Method and system for electrochemically reducing hardness of wastewater

An electrochemical and wastewater technology, applied in chemical instruments and methods, water pollutants, descaling and water softening, etc., can solve the problems of increasing the burden of downstream processing, large electrode consumption, etc., to achieve a simple hard removal process, reduce the burden, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Raw material: 100kg / h filtered gasification wastewater, total hardness 800mg / L, pH=7.9;

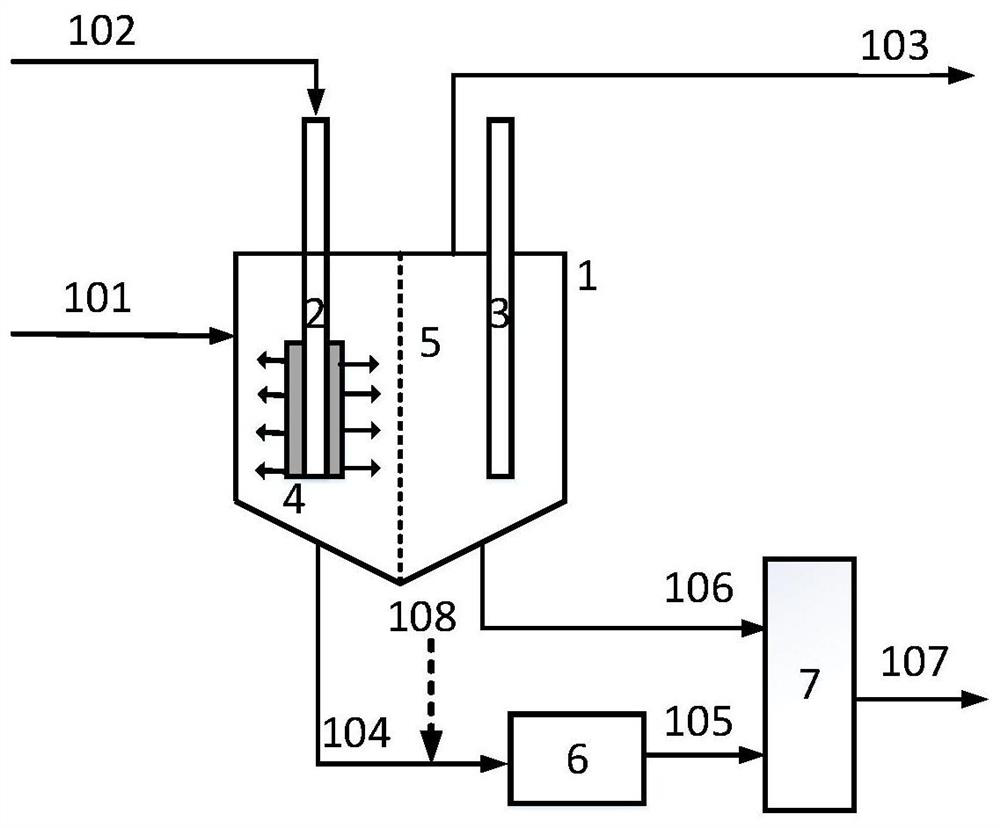

[0085] Such as figure 1 As shown, the above-mentioned raw materials are filtered at room temperature and then passed into an electrochemical hard removal device. In the closed electrolytic cell 1, the electrodes are plate-type inert electrodes, wherein the anode 3 is a graphite electrode, the cathode 2 is a titanium electrode; the ion exchange membrane 5 is a cationic membrane. Adjust the voltage and current so that the voltage is 30-50V, the current is 10-20A, and the temperature is 20-25°C. After electrolysis, a white precipitate is produced in the cathode chamber, and the pH value rises to 12, and the pH value of the anode chamber decreases to 3.5, and the CO 2 The gas 102 is passed into the cathode chamber, the pressure is controlled at 0.2MPa, and the released gas 103 is discharged from the top of the closed electrolytic cell 1; the wastewater 104 in the cathode chamber is f...

Embodiment 2

[0087] Raw material: 100kg / h filtered gasification wastewater, total hardness 800mg / L, pH=7.9;

[0088] Such as figure 1As shown, the above-mentioned raw materials are filtered at room temperature and then passed into an electrochemical hard removal device. In the closed electrolytic cell 1, the electrodes are plate-type inert electrodes, wherein the anode 3 is a graphite electrode, the cathode 2 is a titanium electrode; the ion exchange membrane 5 is a cationic membrane. Adjust the voltage and current so that the voltage is 30-50V, the current is 10-20A, and the temperature is 20-25°C. After electrolysis, a white precipitate is produced in the cathode chamber, and the pH value rises to 12, and the pH value of the anode chamber decreases to 3.5, and the CO 2 The gas 102 is passed into the cathode chamber, the pressure is controlled at 0.2 MPa, and the released gas 103 is discharged from the top of the closed electrolytic cell 1; the cathode chamber wastewater 104 is neutrali...

Embodiment 3

[0090] Raw materials: 100kg / h filtered gasification wastewater 101, total hardness 800mg / L, pH=7.9;

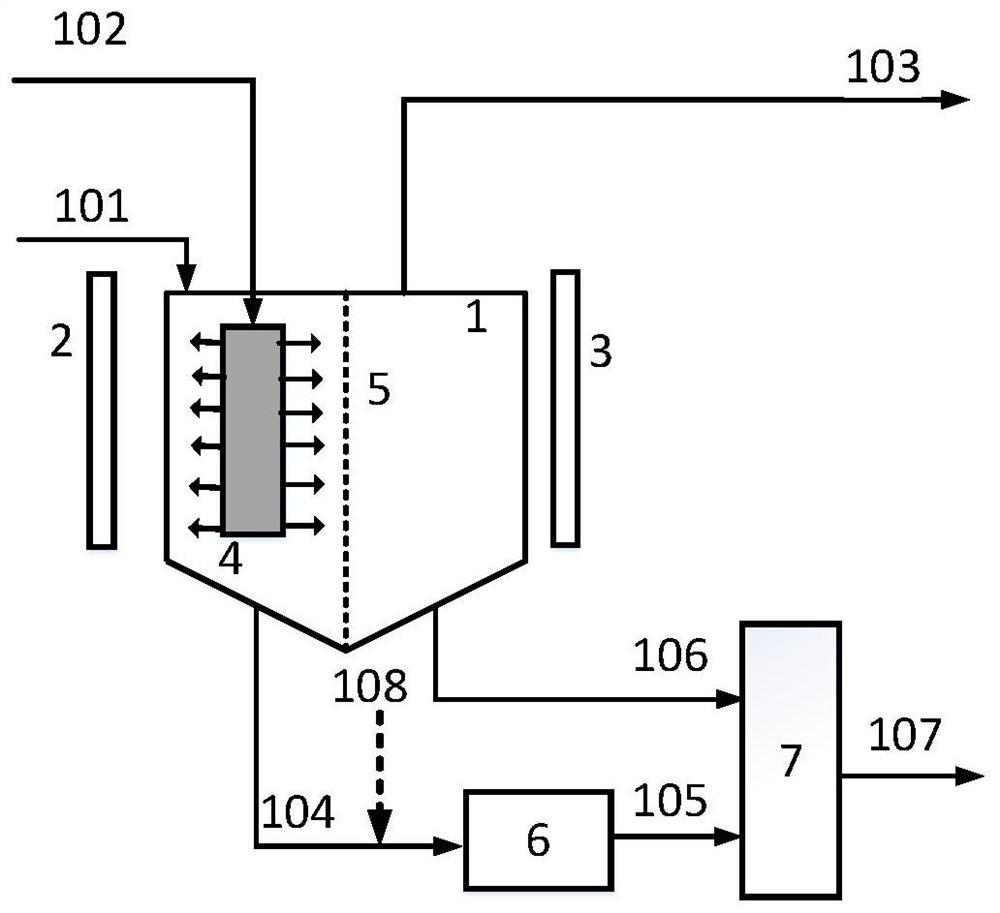

[0091] Such as figure 2 As shown, the above-mentioned raw materials are filtered at room temperature and then passed into an electrochemical hard removal device. In the closed electrolytic cell 1, the electrodes are plate-type inert electrodes placed on both sides outside the electrolytic cell; the ion exchange membrane 5 is a cationic membrane. The electrolytic cell is divided into a cathode chamber and an anode chamber, and the voltage and current are adjusted so that the voltage is 30-50V, the current is 10-20A, and the temperature is 20-25°C. While powering on, the CO 2 The gas 102 is passed into the cathode chamber, the control pressure is 0.2MPa, and the release gas 103 is discharged from the top of the electrolytic cell; the cathode chamber waste water 104 is neutralized with the alkali 108, and a large amount of white precipitates appear, which are filtered by the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com