A sail hull structure

A sail and hull technology, applied in the direction of hull, hull parts, hull design, etc., can solve the problems of unable to further reduce the energy consumption of the ship, limited sail boosting effect, and constraints on the size of the sail, to achieve compact structure, increased thrust, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

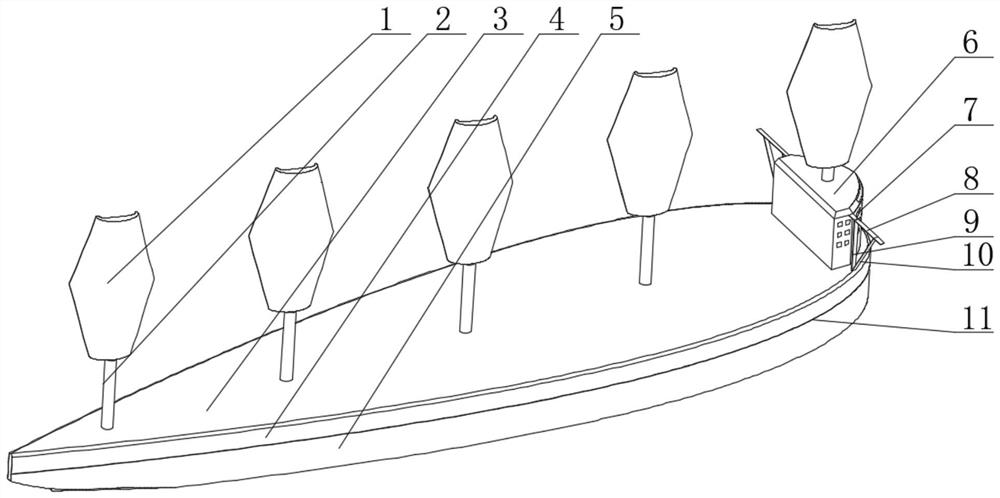

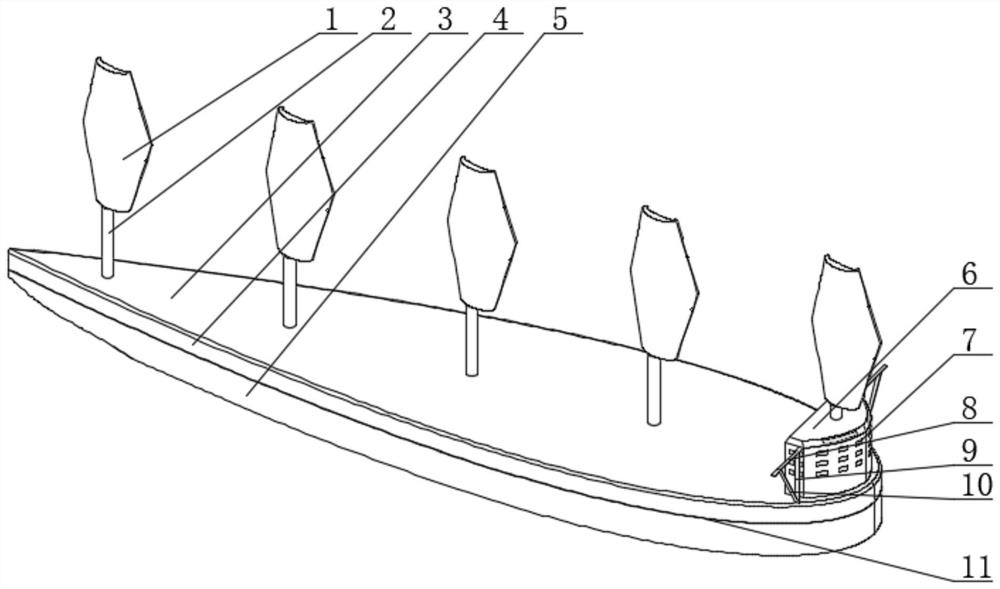

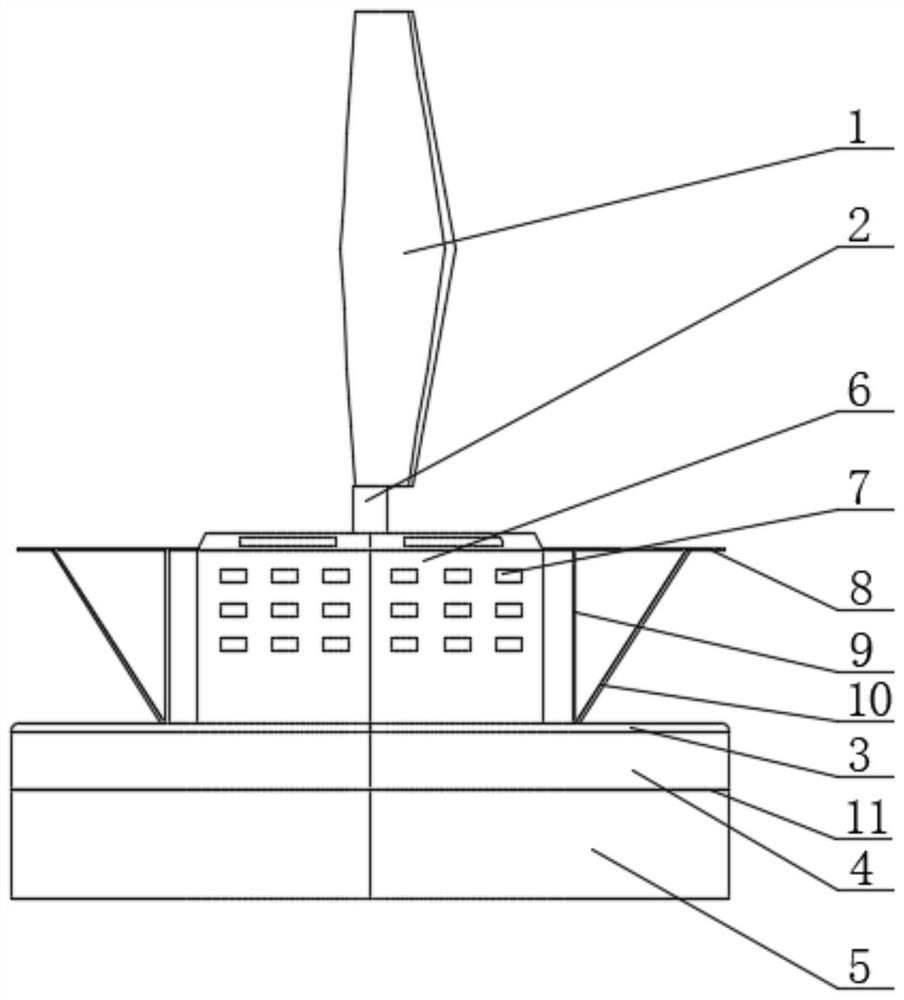

[0039] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention will be described.

[0041] Four struts 2 are installed on the deck 3.

[0042] All sails 1 have the same structure and are located at the same height.

[0043] The strut 2 on the top surface of the driving building 6 is shorter than the strut 2 on the deck 3.

[0044] The cross section of a single sail 1 is an arc structure, and the end face is a rhombus structure.

[0045] A waterline 11 is formed between the upper half body 4 and the lower half body 5.

[0046] The upper half main body 4 adopts a NACA0015 profile.

[0047] The cross section of the lower body half 5 is matched with the upper body half 4.

[0048] A tail structure 401 is installed at the tail portion of the bottom surface of the lower half main body 5, and the cross section of the tail structure 401 is triangular.

[0049] The width of the driving building 6 is less than or equal to the width of the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com