Modular high-expansion-and-contraction-rate robot based on paper folding mechanism

A robotic and modular technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of limited robot application range, complex structure, high failure rate, etc., to achieve good flexibility and adaptability, firm structure, and easy operation flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, for the convenience of describing the structural features of the present invention and simplifying the description, in the description of the present invention, the terms "upper", "lower", "top", "bottom", "one side", "another side" The orientation or positional relationship indicated by , "left", "right", etc. is based on the orientation or positional relationship shown in the drawings, and does not mean that the structure must have a specific orientation, be constructed and operated in a specific orientation.

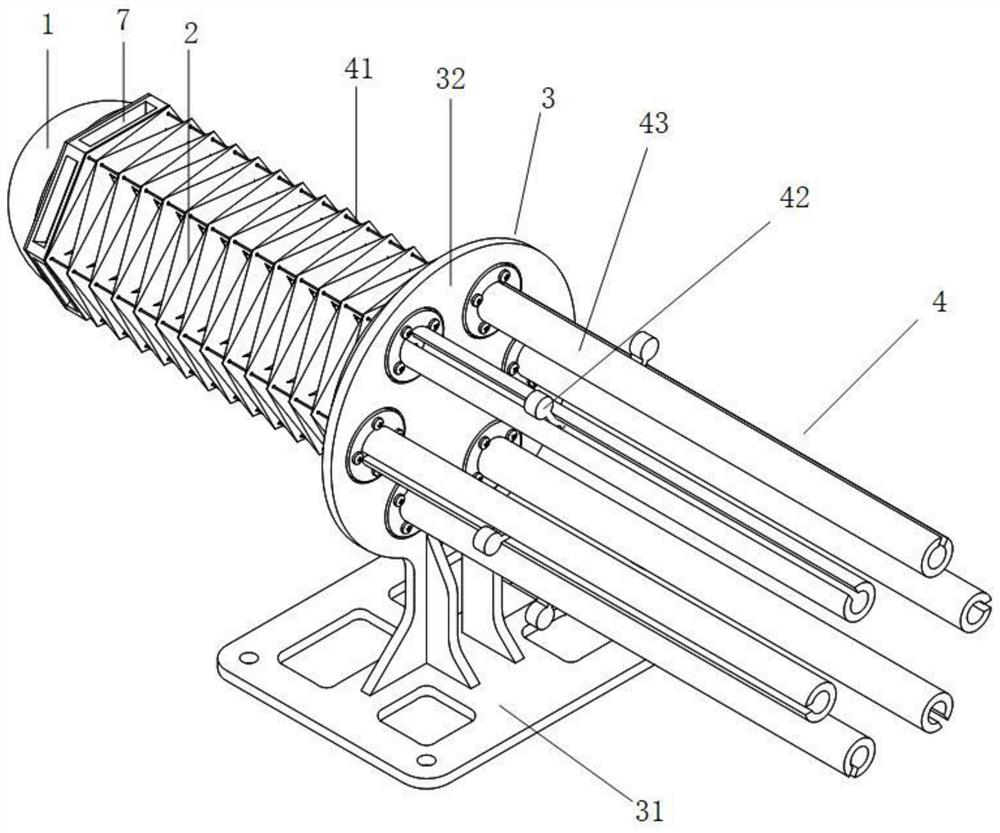

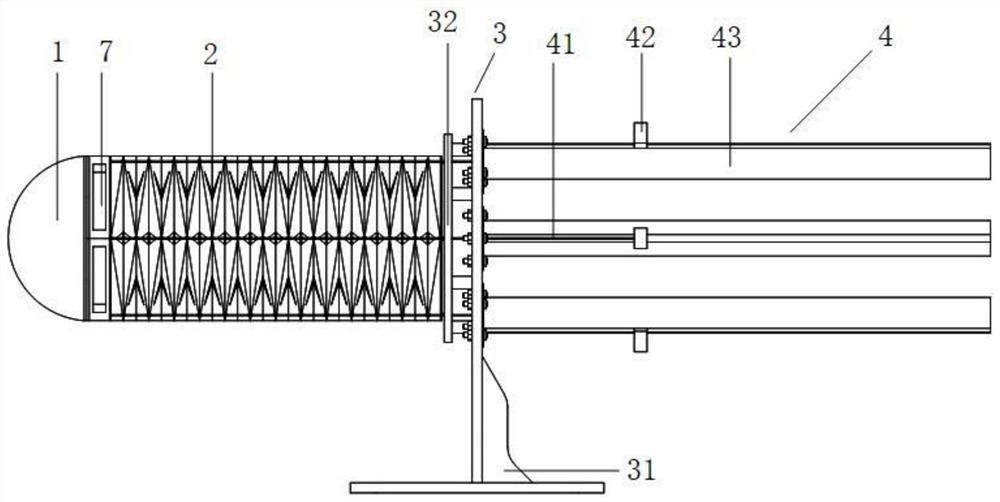

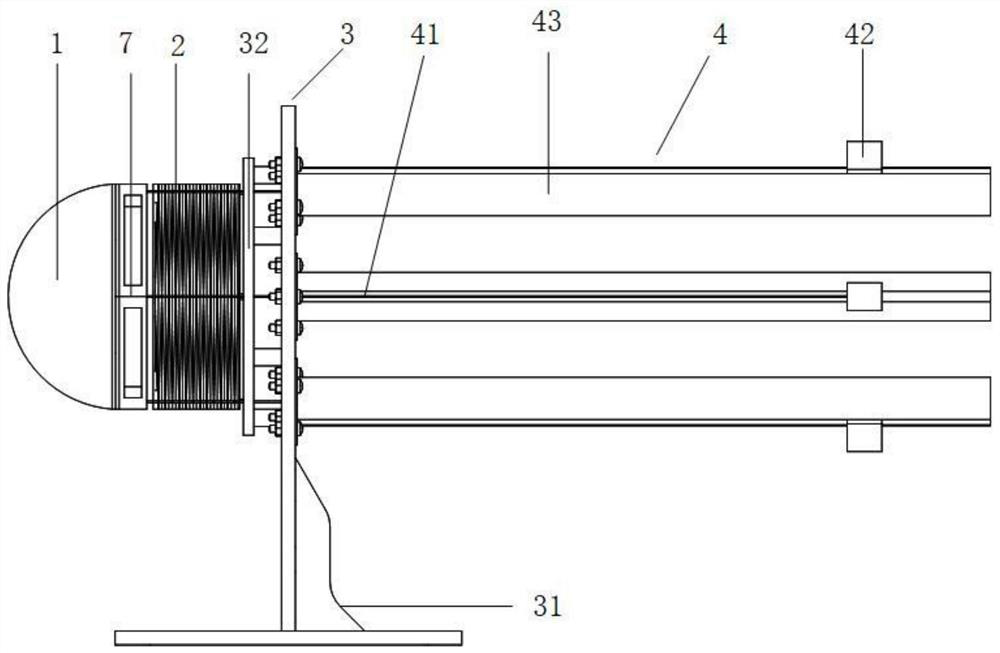

[0038] Such as Figure 1 ~ Figure 3 As shown, the origami mechanism-based modular high-stretch-rate robot disclosed in the present invention includes a robot end effector 1 , an origami module 2 , a base 3 and a drive module 4 . The origami module 2 and the driving module 4 are installed on both sides of the base 3 respectively, the robot end effector 1 is installed at the end of the origami module 2 through the connecting module 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com