Waste recovery device for shale brick production

A technology of waste recycling and shale bricks, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of increasing the number of equipment, high cost, and increased site costs, and achieve the effect of avoiding blocking the mesh and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

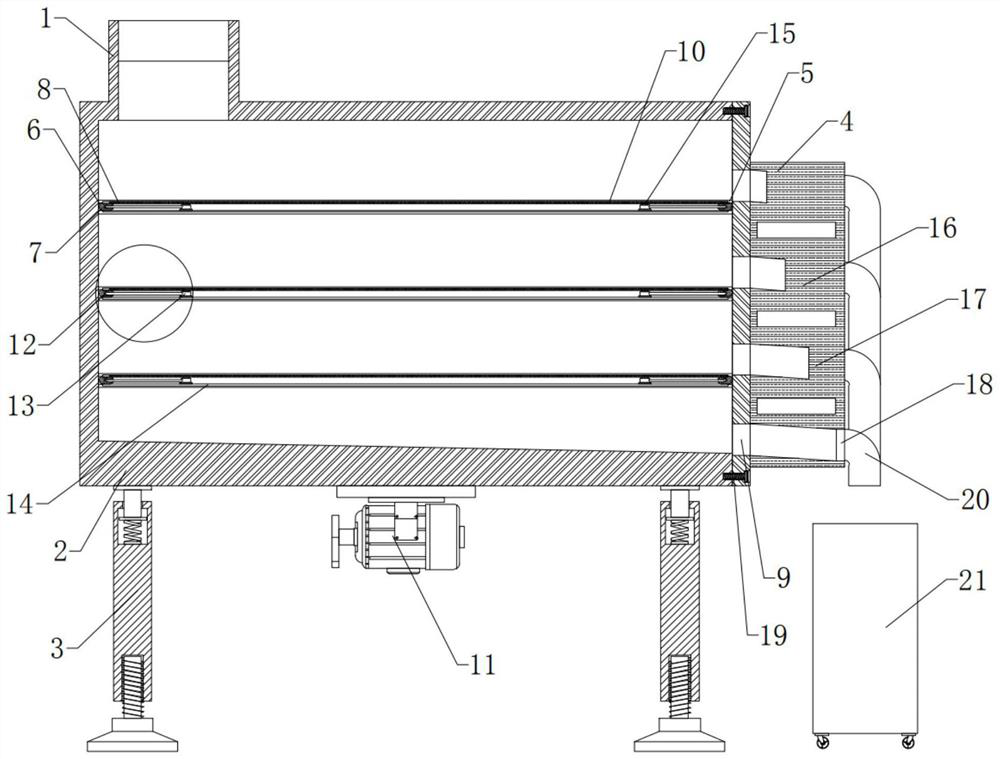

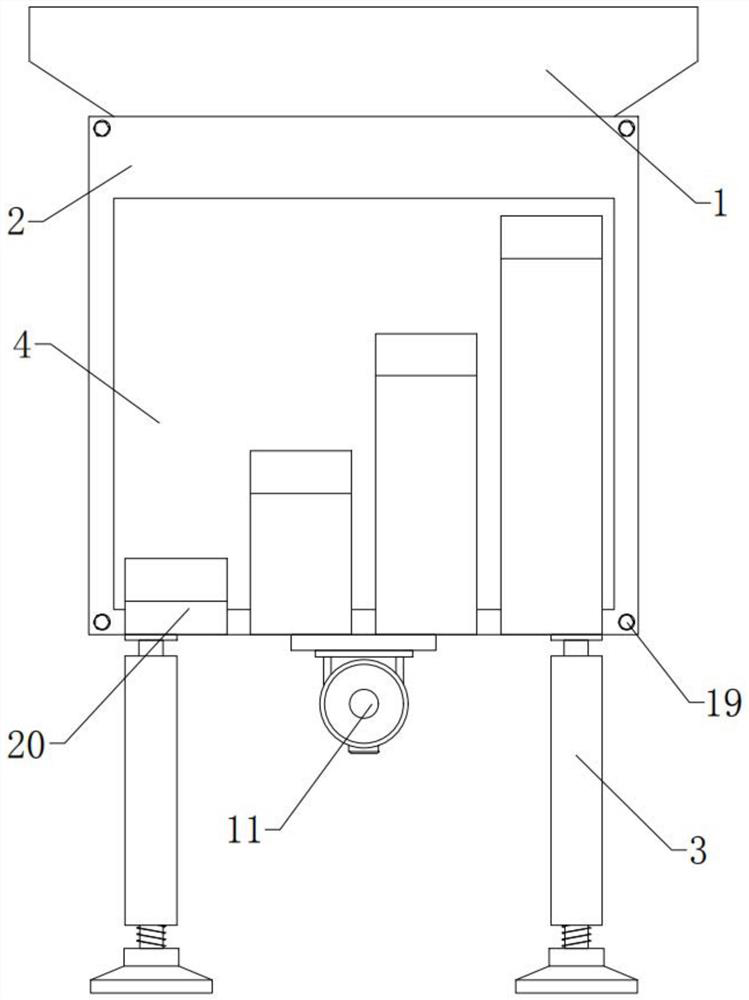

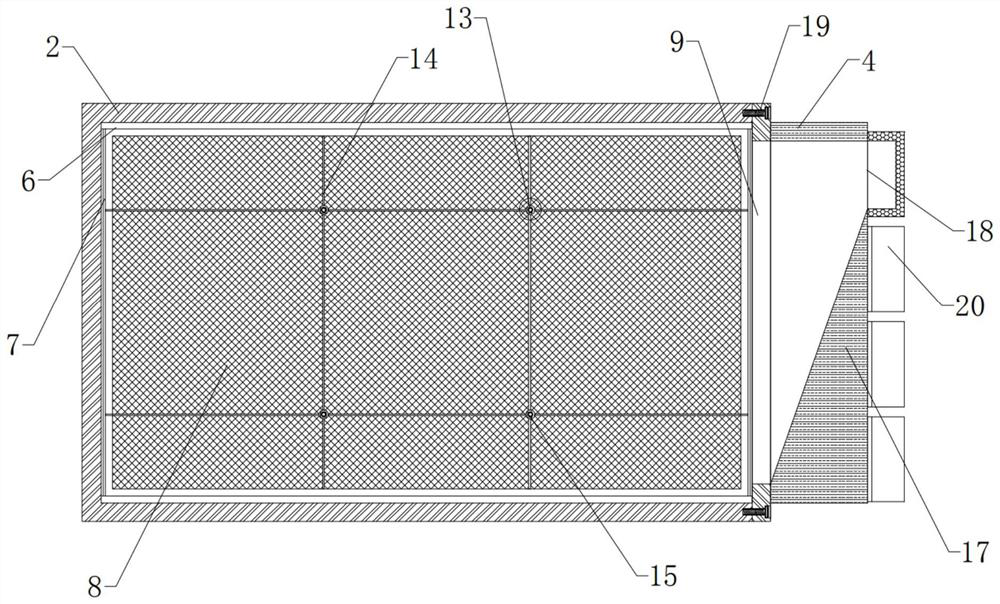

[0027] Embodiment: according to specification Figure 1-5 It can be seen that this case is a waste recovery device for shale brick production, including a feed hopper 1, a treatment box 2, two pairs of adjustable feet 3 and a material distribution trough 4, and a feed trough is provided on the side wall of the treatment box 2. The feed hopper 1 is installed on the side wall of the treatment box 2 and communicates with the feed tank. The bottom surface of the treatment box 2 is provided with two pairs of adjustable legs. The distribution tank 4 is installed on the side wall of the treatment box 2. The treatment box 2 There are several particle size layered structures inside, and a suspension vibration structure is arranged on several particle size layered structures, and a material distribution storage structure is provided under the material distribution tank 4. In the specific implementation process, the material is passed into the In the treatment box 2, the feed hopper 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com