A variable caliber magnetically controlled inner helical vascular robot

A robot and internal spiral technology, applied in the field of vascular robots, can solve the problems of unstable movement process, slow progress of micro-robots, insufficient power, etc., and achieve the effects of improving flexibility, increasing pressure difference, and increasing movement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

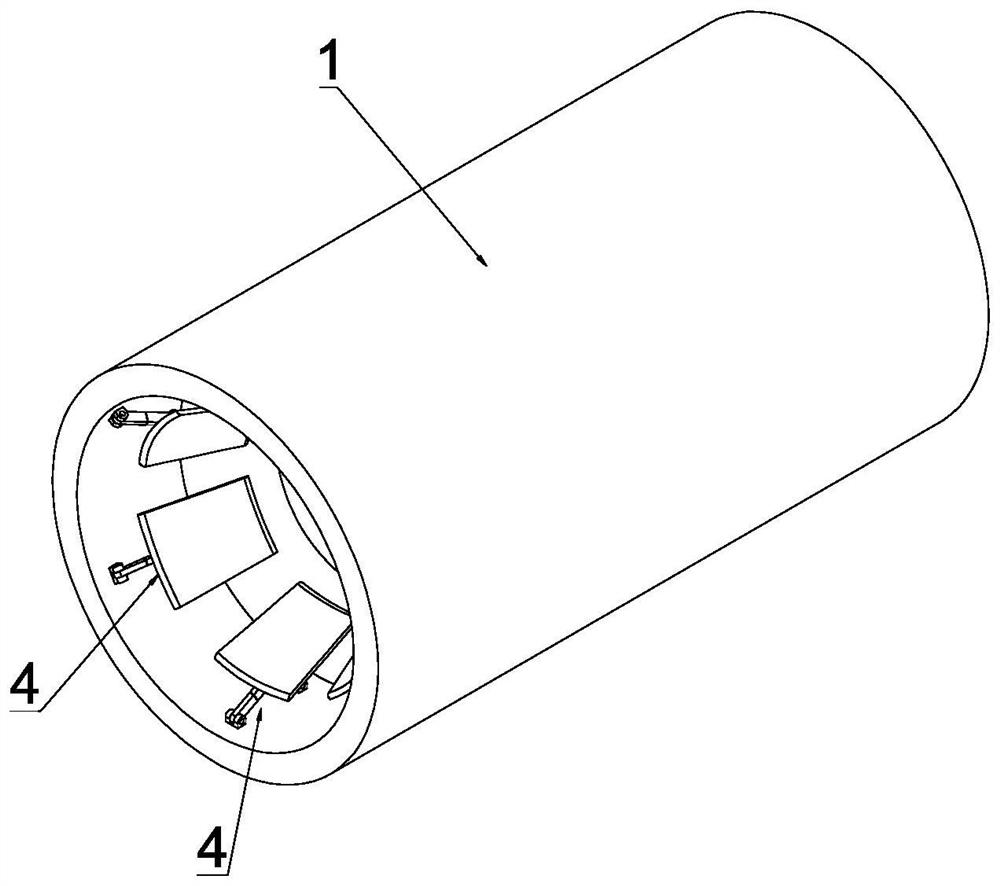

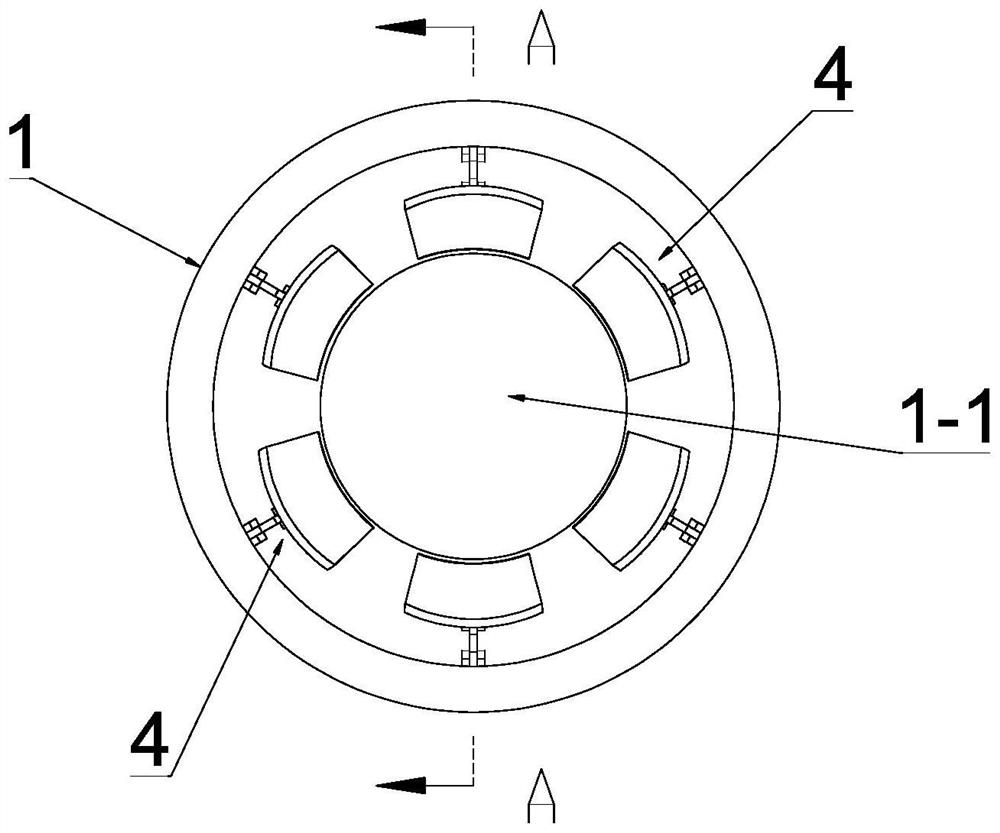

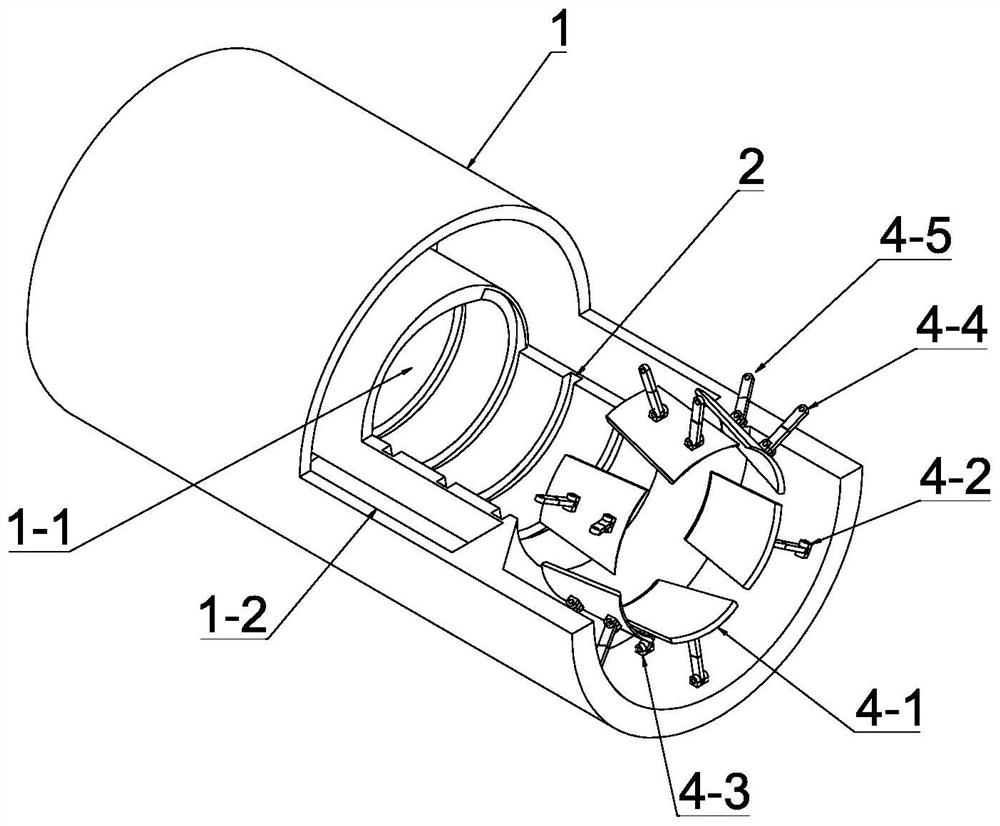

[0036] see Figure 1-Figure 5 , this embodiment discloses a magnetically controlled inner helical vascular robot with variable caliber, including a robot main body 1, a permanent magnet (not shown in the figure), a magnetic field generating device (not shown in the figure) and an execution device (not shown in the figure). shown), the robot main body 1 is a tubular body, and the robot main body 1 has a hollow cavity 1-1 passing through the robot main body 1 and an annular inner cavity 1 coaxially arranged with the hollow cavity 1-1 -2. Both the permanent magnet and the actuator are installed in the annular inner cavity 1-2. The hollow cavity 1-1 includes a drive cavity 1-11 in the middle and a drive cavity 1-11. The installation cavities 1-12 at the front and rear ends, the inner wall of the drive cavity 1-11 is provided with a spiral groove 2, wherein, each of the installation cavities 1-12 is fixed with an elastic ring belt-shaped film 3, the The elastic ring-shaped film 3 ...

Embodiment 2

[0059] see Figure 6-Figure 7 , the other specific structures in this embodiment are the same as in Embodiment 1, the difference is that the movable connection structure includes a hinge seat 4-6 arranged on the inner wall of the installation cavity 1-12, and the adjustment blade 4-1 is One end close to the end of the hollow cavity 1-1 is hinged on the hinge seat 4-6, and the material of the regulating blade 4-1 is magnetic material. With the above-mentioned structure, the axial magnetic field generates a magnetic moment on the adjusting blade 4-1, and under the joint action of the blood impact and the magnetic moment, the adjusting blade 4-1 is made to swing, and the elastic ring belt-shaped film 3 is continuously squeezed during the swinging process, so that The caliber of the elastic ring belt-shaped film 3 changes, thereby controlling the size of the openings at both ends of the robot main body 1 .

[0060] see Figure 6-Figure 7 , one end of the regulating vane 4-1 hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com