Sulfur-containing standard substance as well as preparation method and application thereof

A standard substance and standard value technology, applied in the field of chemical metrology, can solve the problem that the carbon-sulfur meter cannot meet the analysis requirements, and achieve the effect of meeting the needs of rapid analysis in front of the furnace, reducing costs, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Preparation of standard materials

[0056] 1. Preparation of Flux

[0057] Select 1.5 parts of pure tungsten powder, 0.5 parts of pure iron powder, mix well, press and form, sinter to obtain sintered material, take the sintered material granules with a particle size of 20 mesh to 40 mesh, and select 0.2 part of tin particles with a particle size of 20 mesh to 60 mesh , 0.2 parts of 60-300-mesh vanadium pentoxide, mixed with the prepared sintered pellets, and calcined at 800°C-1100°C to obtain a flux.

[0058] 2. Crush, mix and sieve the flux to obtain candidates.

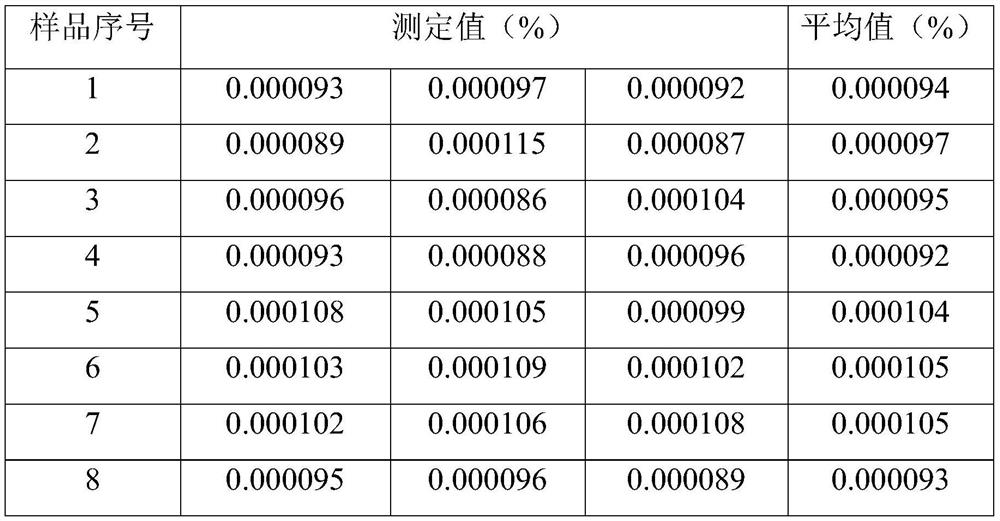

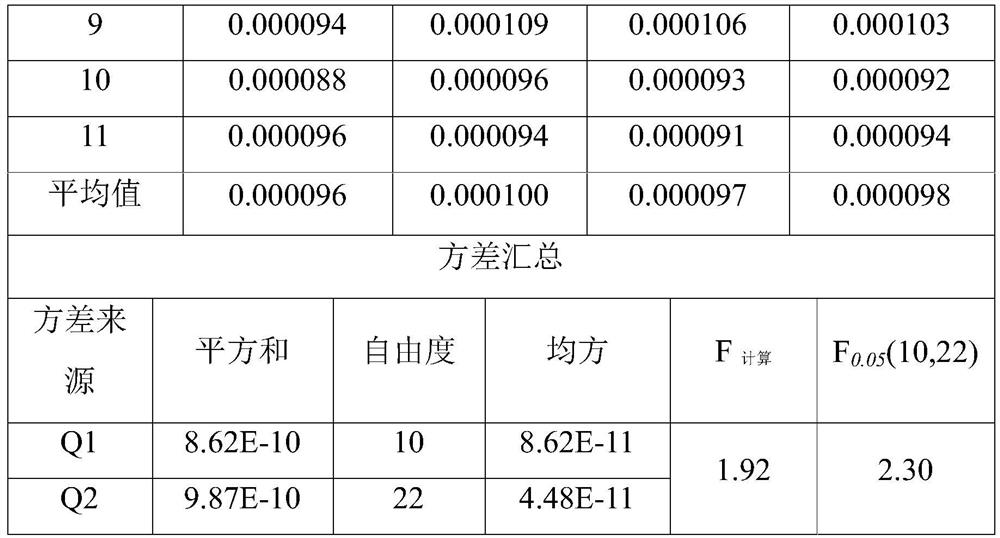

[0059] 3. In accordance with the "Technical Specifications for Primary Standard Substances" (JJF 1006-1994), the candidate was subjected to homogeneity test, stability test, fixed value, determination of standard value and estimation of total uncertainty. The final result showed that the candidate Good material uniformity and stability, the standard value of sulfur S: 0.00010% ± 0.00001%.

[0060] (1) U...

Embodiment 2

[0139] 1. Preparation of standard materials

[0140] 1. Preparation of Flux

[0141] Select 2.0 parts of pure tungsten powder and 1 part of pure iron powder, mix well, press and form, and sinter to obtain a sintered product. The obtained sintered product is crushed and sieved, and the sintered product particles with a particle size of 20 mesh to 40 mesh are taken. 0.5 parts of copper particles with a particle size of 20 mesh to 60 mesh, mixed with the prepared sintered material pellets, and calcined at 1350°C to 1400°C to obtain a flux;

[0142] 2. Crush, mix and sieve the flux to obtain candidates;

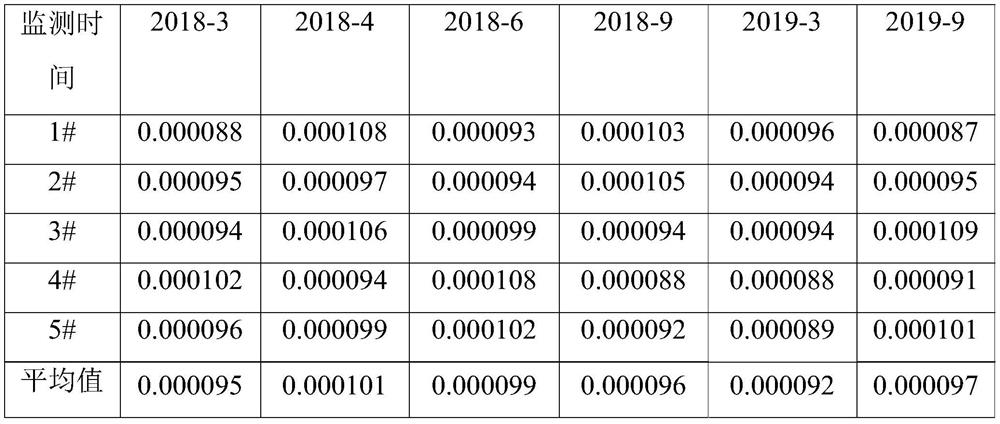

[0143] 3. In accordance with the "Technical Specifications for Primary Standard Substances" (JJF 1006-1994), the candidate was tested for homogeneity, stability, fixed value, standard value and total uncertainty. The final result showed that the candidate Good material uniformity and stability, the standard value of sulfur S: 0.00040% ± 0.00003%.

[0144] (1) Uniformity test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com