TEP-based coagulant regulation and control method and application thereof

A coagulant and data technology, applied in the direction of measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problem of lack of exploration of the mechanism of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

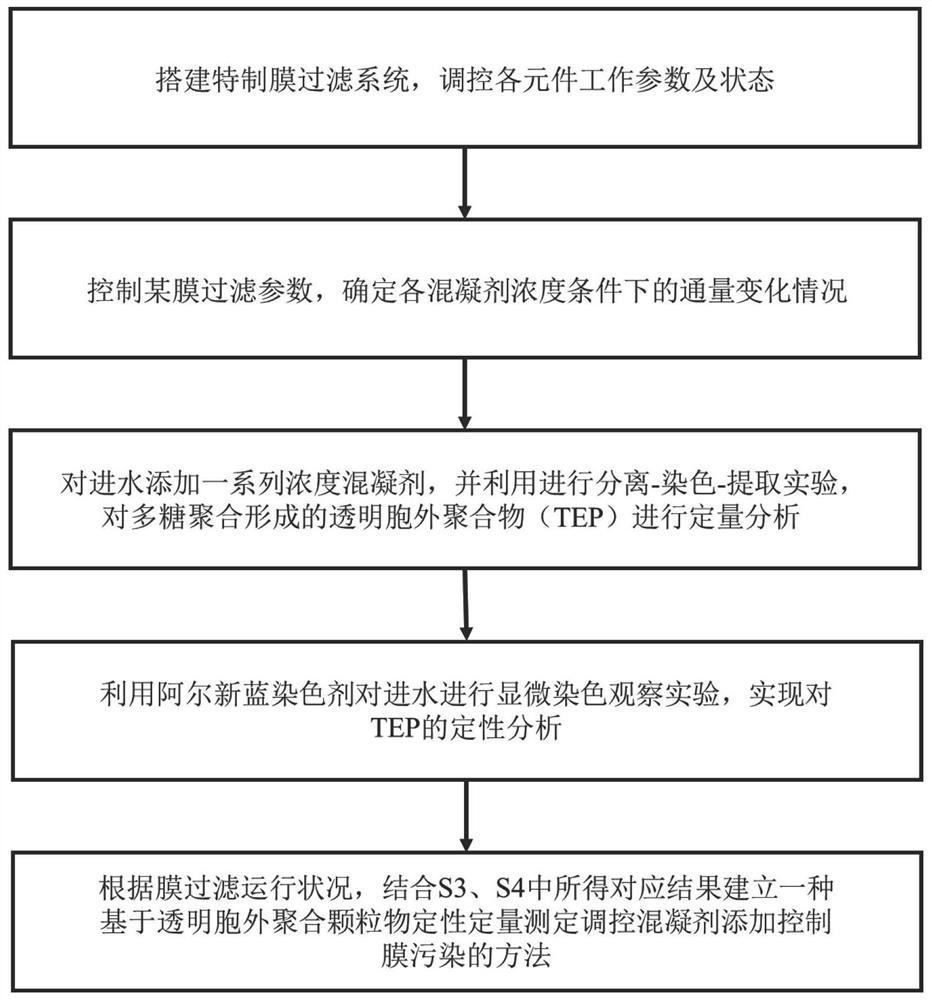

Method used

Image

Examples

Embodiment 3

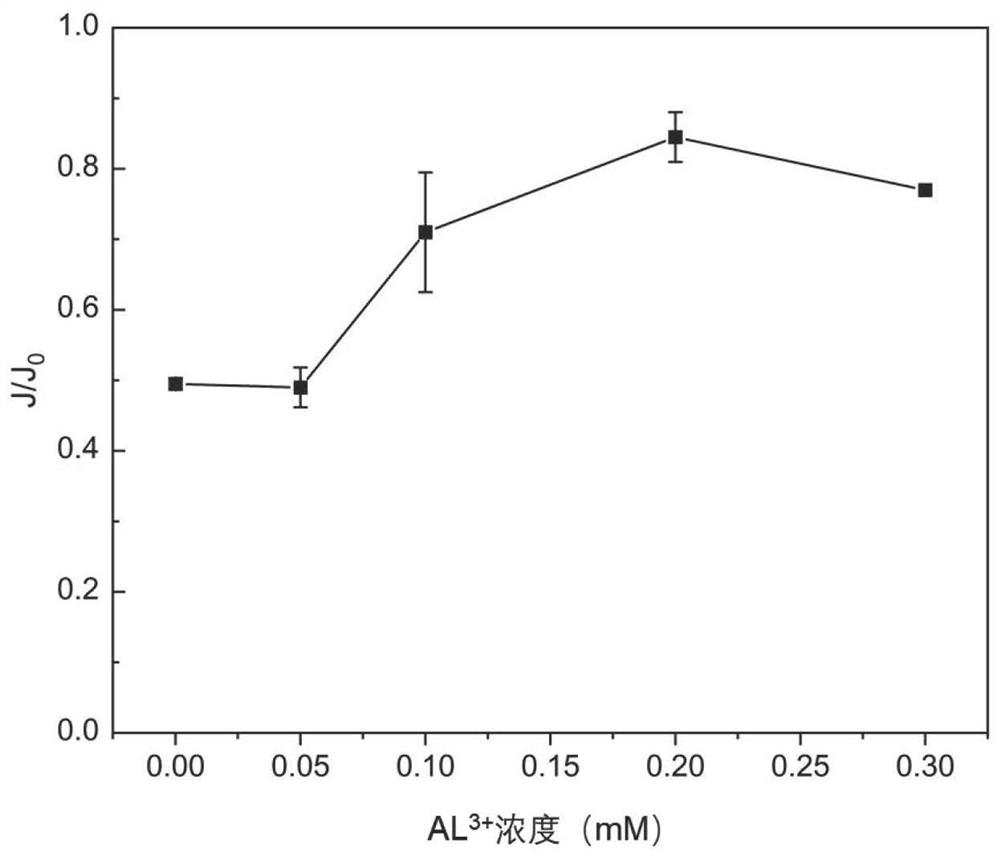

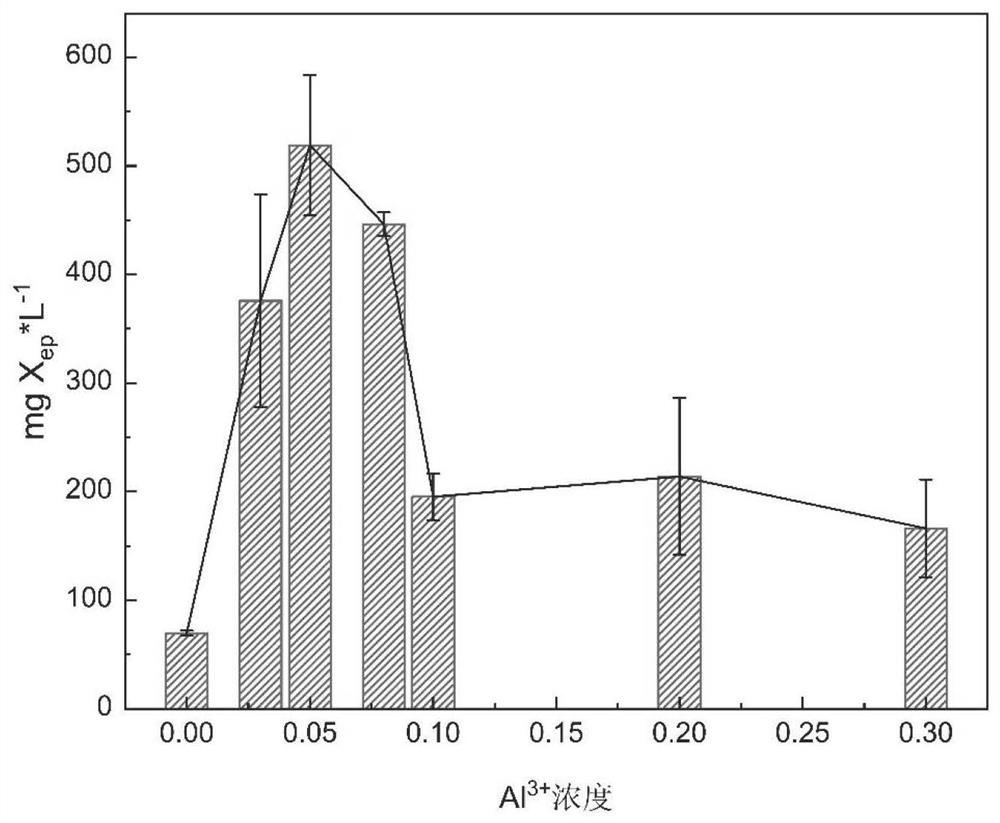

[0060] In this example, a total of 4 L of liquid was fed, and the liquid fed contained water and sodium alginate, wherein the concentration of sodium alginate was 50 mg / L. After the solution was prepared, it was stirred with a magnetic stirrer for 2 hours to ensure that the solution was fully mixed. The cross-flow filtration device built in the first embodiment of the present invention was used to carry out membrane filtration tests, wherein the membrane module equipped with the membrane unit was a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 20kDa, the cross-flow filtration time was 120min, and the constant pressure was 2bars , the balance connected to the computer records the weight change every 15-60s, and calculates the membrane resistance according to Darcy's law.

Embodiment 4

[0062] This embodiment enters a total of 4L of liquid, which contains water, sodium alginate and aluminum ion coagulant, wherein the concentration of sodium alginate is 50mg / L, and the concentration of aluminum ion is 0.05mM. After the solution is prepared, use a magnetic stirrer to Stir for 2 h, ensuring that the solution is well mixed. Membrane filtration experiments were carried out using the cross-flow filtration device built in the first embodiment of the present invention. The equipped membrane module is a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 20kDa, the cross-flow filtration time is 120min, the constant pressure is 2bars, the balance connected to the computer records the weight change every 15-60s, and the membrane resistance is calculated according to Darcy's law .

Embodiment 5

[0064] This embodiment enters a total of 4L of liquid, which contains water, sodium alginate and aluminum ion coagulant, wherein the concentration of sodium alginate is 50mg / L, and the concentration of aluminum ion is 0.1mM. After the solution is prepared, use a magnetic stirrer to Stir for 2 h, ensuring that the solution is well mixed. Membrane filtration experiments were carried out using the cross-flow filtration device built in the first embodiment of the present invention. The equipped membrane module is a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 20kDa, the cross-flow filtration time is 120min, the constant pressure is 2bars, the balance connected to the computer records the weight change every 15-60s, and the membrane resistance is calculated according to Darcy's law .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com