Method for supporting surrounding rock of diversion tunnel

A technology for surrounding rock support and water diversion tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of limited construction space, long construction period, and long lining period for small-section and extra-long water diversion tunnels, and save personnel management. cost, less cost input, and the effect of speeding up the lining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

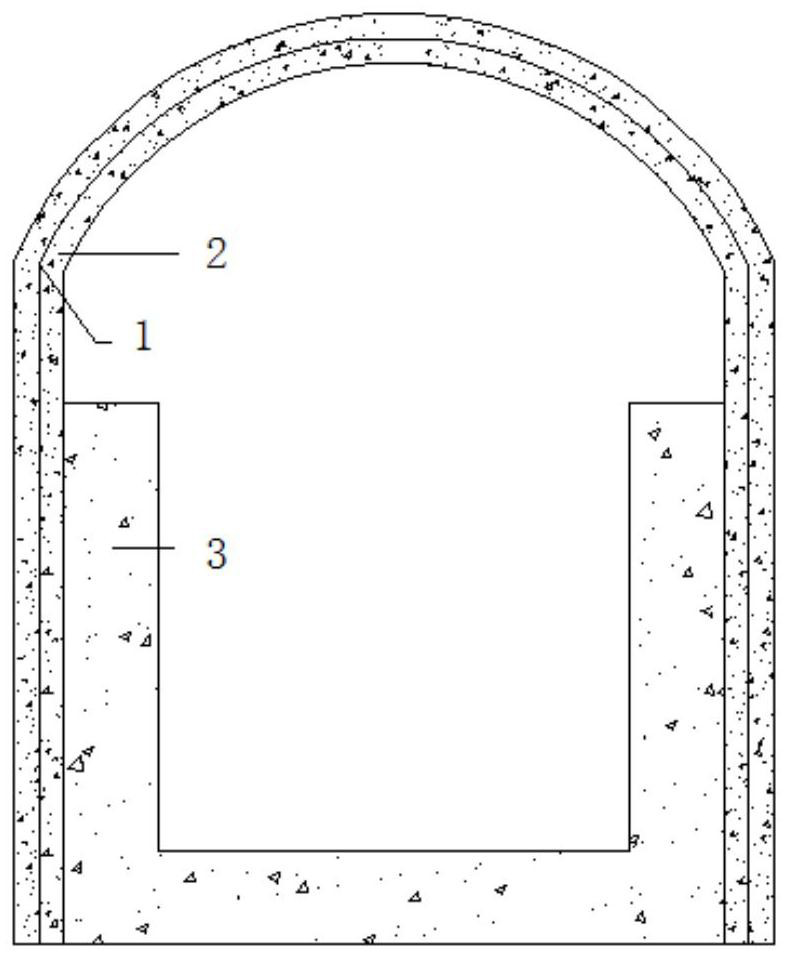

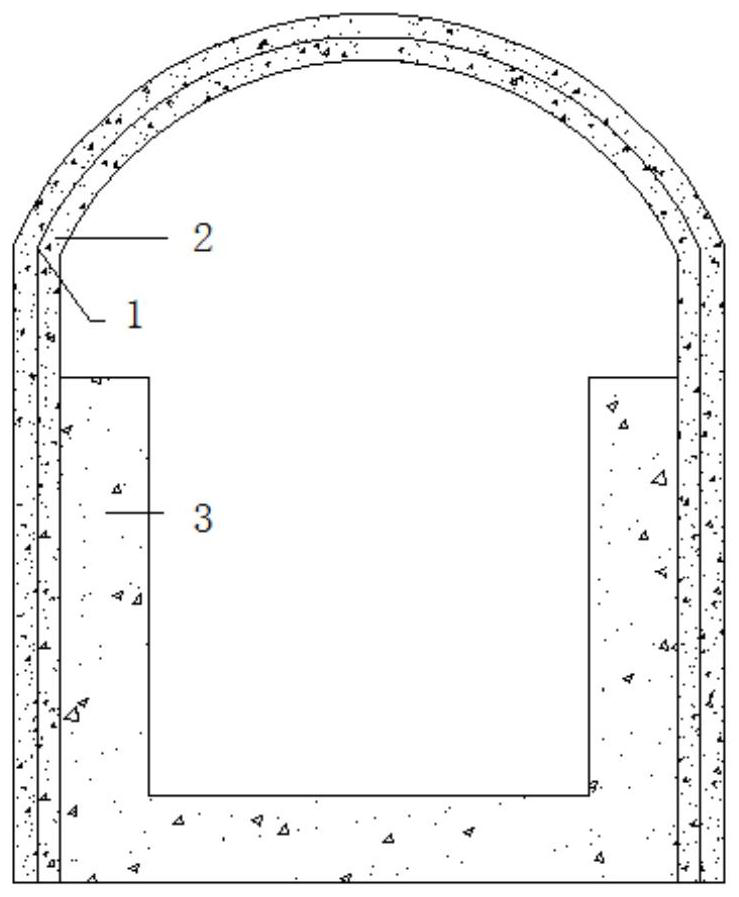

[0048] Specific implementation mode one: a method for supporting the surrounding rock of a water diversion tunnel. This method is applicable to the B2 type support of the IV type surrounding rock and the C1 type support of the V type surrounding rock, and specifically includes the following steps:

[0049] Step 1: Arrange support;

[0050] Use profiled steel pavement 1 as support within the range of the top arch and side walls;

[0051] Step 2: Arrange the anchor rod;

[0052] Lay anchor rods within the scope of the top arch and side walls, and arrange the anchor rods in a row every other support, and arrange three anchor rods in each row.

[0053] Step 3: laying longitudinal connecting bars;

[0054] Lay connecting bars within the range of the top arch and side walls to connect the connecting bars to the supports;

[0055] Step 4: laying steel mesh;

[0056] Lay reinforcement mesh within the scope of the top arch and side walls;

[0057] Step 5: Spray concrete 2;

[0058]...

specific Embodiment approach 2

[0061] Embodiment 2: The anchor rods are all arranged on the support body.

[0062] Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0063] Specific implementation method three: the medium-shaped steel 1 in the step 1 is made of No. 14 I-beam, and the distance between each support is 1.2m; the anchor rod in the step 2 is an M20 mortar C20 anchor rod, and the length of the anchor rod is 1.5 m, and the row spacing of two adjacent rows of anchor rods is 2.4m, the longitudinal connecting bars in the step 3 adopt C16 steel bars, the circumferential spacing of the longitudinal connecting bars is 1.0m, and the reinforcing mesh in the step 4 is A6 steel mesh , the inter-row spacing of steel mesh is 200mm * 200mm; Concrete 2 is C20 concrete in described step five, and concrete 2 spraying thickness is 160mm; Plain concrete 3 is C30 plain concrete in described step six, and the spraying thickness of plain concrete 3 is 300mm.

[0064] Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com