Feeding device for shrinkage setting in textile production

A technology of feeding device and sizing cylinder, which is applied to the processing of textile materials, processing of textile material drums, and processing of textile material carriers, etc., which can solve the problems of cloth changes, unqualified cloth quality, and affecting the effect of cloth shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

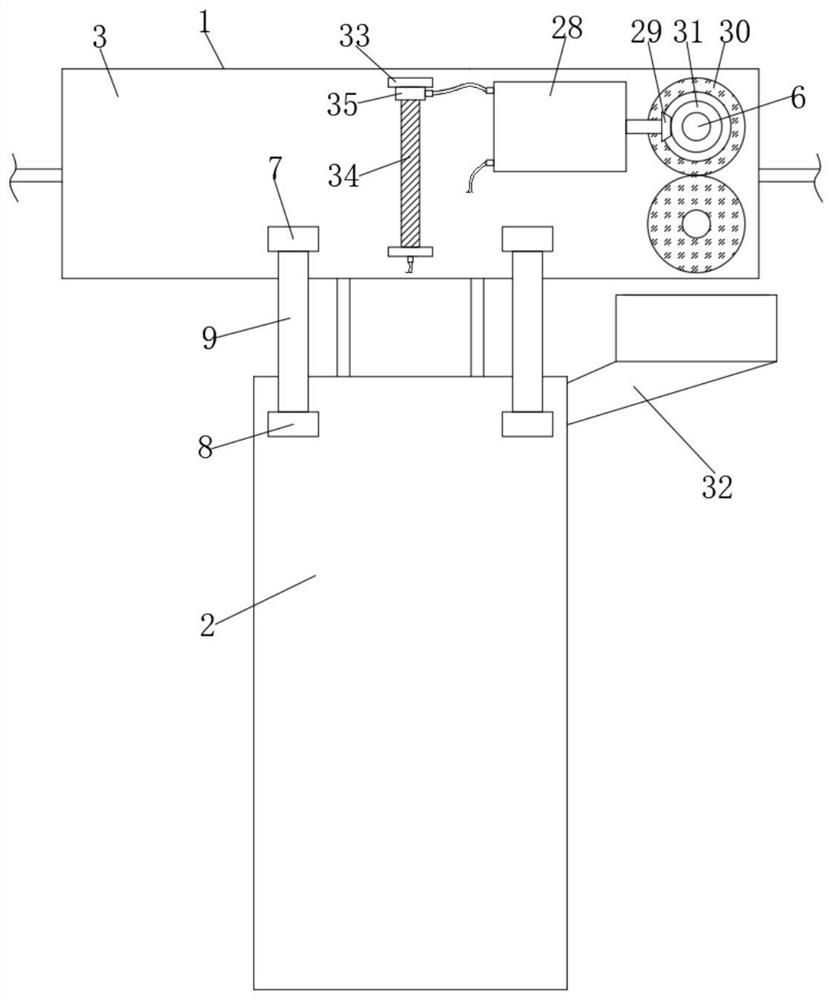

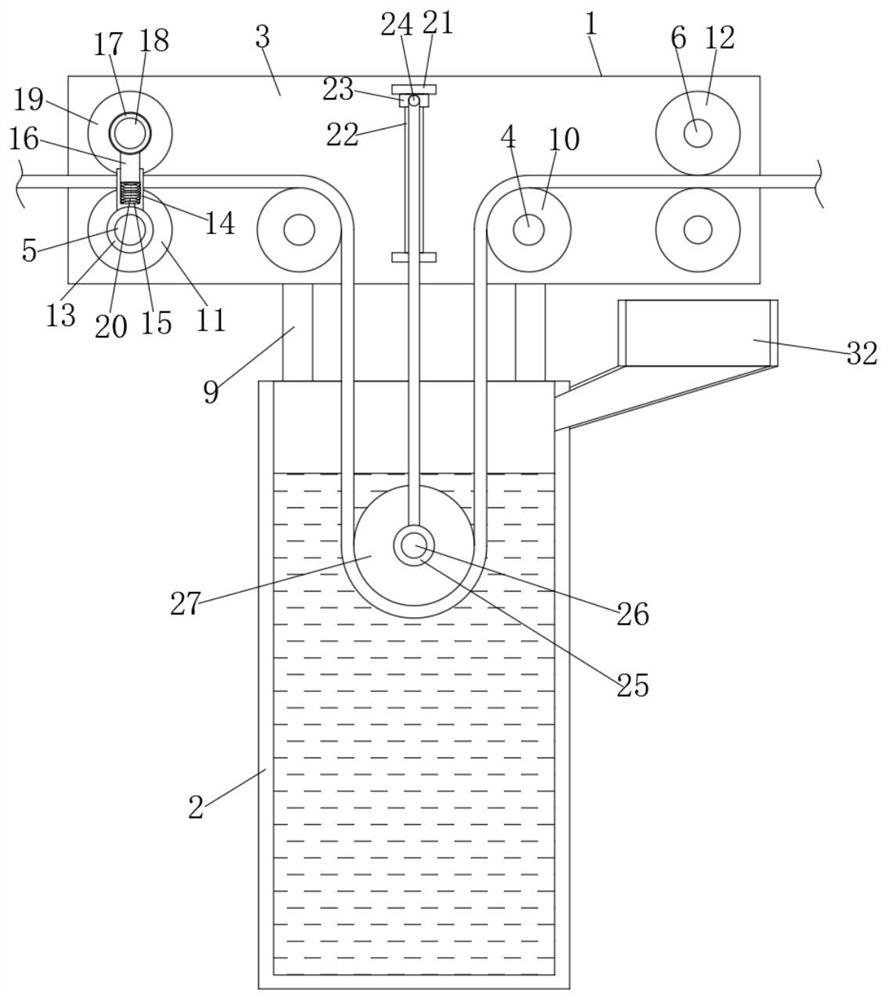

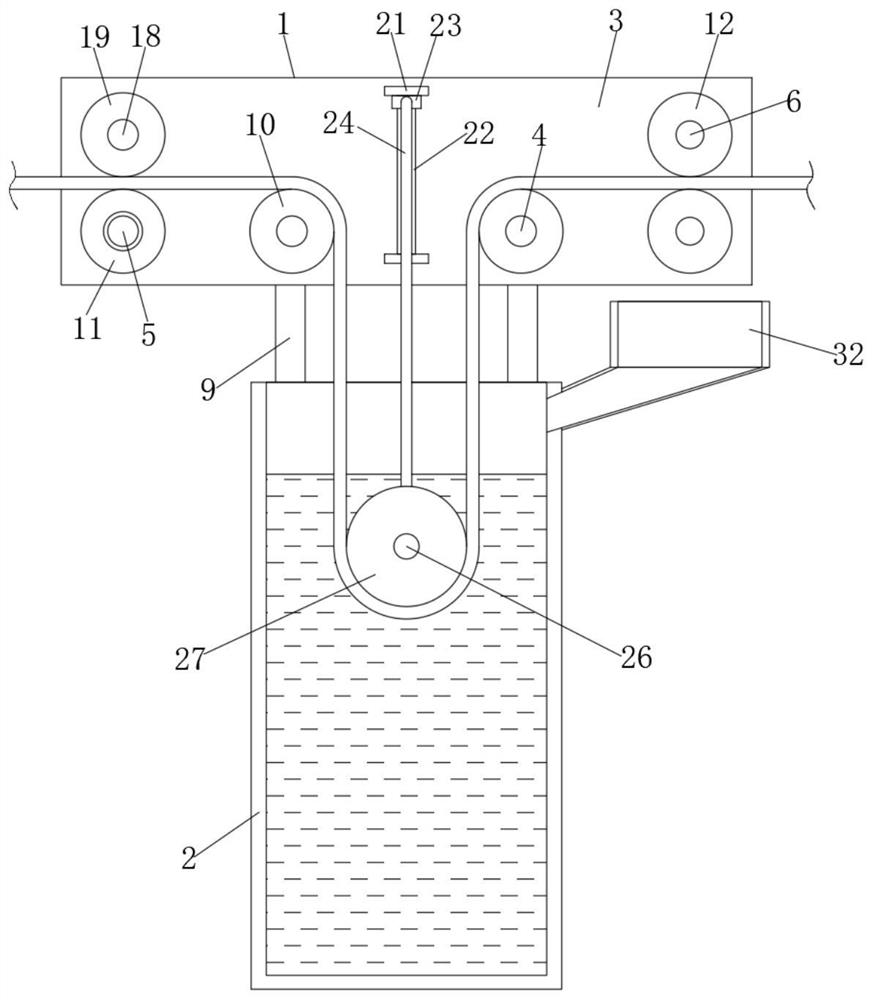

[0021] Refer Figure 1-4 , A woven production of a grease-shaped feed apparatus, including the frame 1 and the immersion stylus 2, and the soaking stack 2 has a stitcher, the frame 1 is fixed to the immersion stylus 2, and the frame 1 includes two baffles. 3, the two baffle 3 is symmetrically fixed to two fixing rods 4, and there is a damping shaft 5 between the two baffles 3, and the two baffle 3 rotate between the two transmission shafts 6, the baffle 3 Symmetrical fixation is coupled with a plurality of first connecting members 7, and the solenoided cartridge 2 is fixedly coupled with a plurality of second connecting members 8, and the first connecting member 7 and the second conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com