Tungsten bronze-based super-hydrophobic transparent thermal insulation coating and preparation method thereof

A heat-insulating coating and super-hydrophobic coating technology, which is applied in chemical instruments and methods, coatings, tungsten compounds, etc., can solve the problems of high price, complicated preparation process, and easy oxidation of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of tungsten bronze-based transparent heat-insulating paint, comprising the following steps:

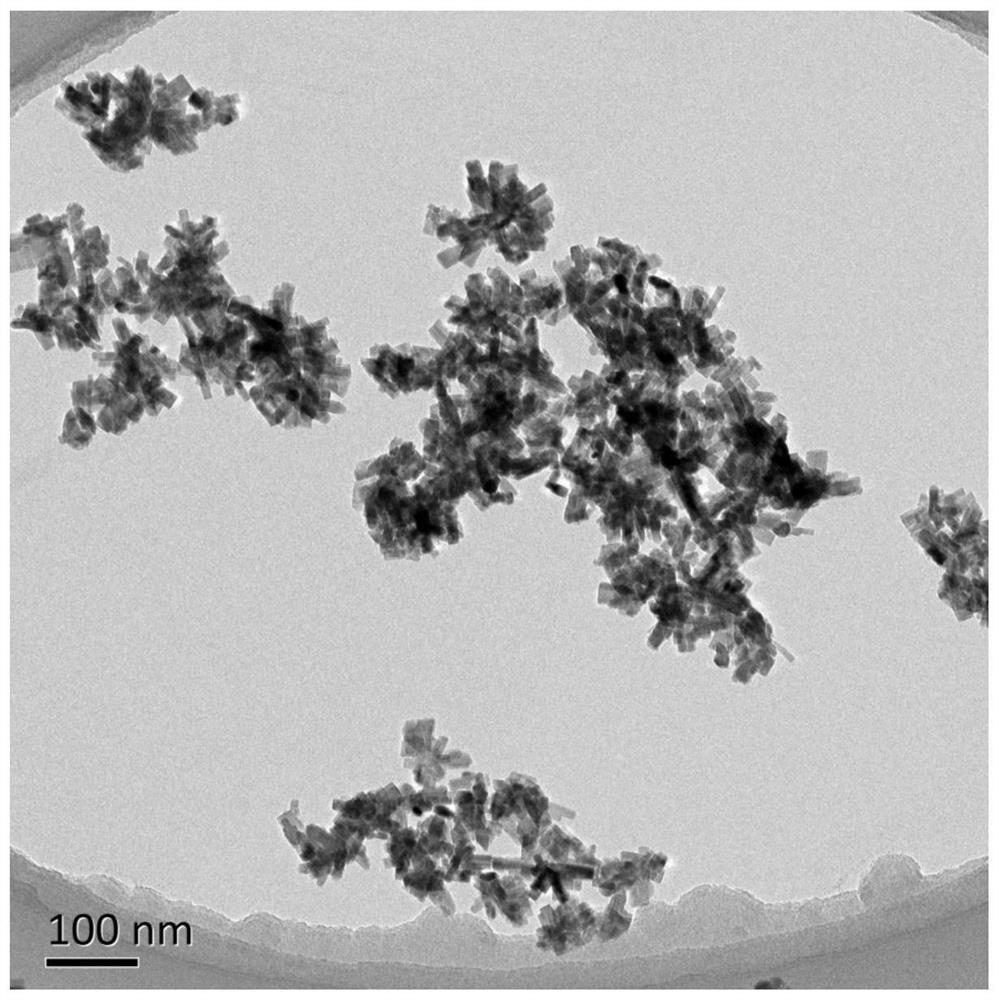

[0054] 1) Measure 63ml of benzyl alcohol and pour it into a 100ml beaker, weigh 0.6000g of tungsten chloride and pour it into benzyl alcohol, dissolve it ultrasonically to obtain an orange-red clear solution; then weigh 0.1270g of cesium hydroxide monohydrate and add it to the above Solution, ultrasonically stirred for five minutes to obtain an orange-red transparent clear solution, then add 7ml oleic acid to it, stir evenly, transfer the above solution to the lining of a 100ml p-polyphenyl reactor, put the reactor into an oven, and keep Reaction at 220°C for 8h. After the reaction is finished, the reactant is naturally cooled, washed with absolute ethanol for 6 times, centrifuged and dried at 60°C for 8 hours to obtain cesium tungsten bronze nanopowder; figure 2 The topography of its cesium tungsten bronze powder shows that the synthesized nano-powder is...

Embodiment 2

[0062] A preparation method of tungsten bronze-based transparent heat-insulating paint, comprising the following steps:

[0063] (1) Measure 63ml of benzyl alcohol and pour it into a 100ml beaker, weigh 0.6000g of tungsten chloride and pour it into benzyl alcohol, dissolve it ultrasonically to obtain an orange-red clear solution; then weigh 0.1270g of cesium hydroxide monohydrate and add The above solution was ultrasonically stirred for five minutes to obtain an orange-red transparent clear solution, then 7ml oleic acid was added thereto, stirred evenly, the above solution was transferred to the lining of a 100ml p-polyphenyl reactor, and the reactor was put into an oven. Keep the reaction at 220°C for 8h. After the reaction, the reactant was cooled naturally, washed with absolute ethanol for 6 times, centrifuged and dried at 60°C for 10 hours to obtain cesium tungsten bronze nanopowder;

[0064] (2) Add 1g of cesium tungsten bronze nanopowder into 20ml of n-hexane, after sti...

Embodiment 3

[0069] A preparation method of tungsten bronze-based transparent heat-insulating paint, comprising the following steps:

[0070] (1) Measure 63ml of benzyl alcohol and pour it into a 100ml beaker, weigh 0.6000g of tungsten chloride and pour it into benzyl alcohol, dissolve it ultrasonically to obtain an orange-red clear solution; then weigh 0.1270g of cesium hydroxide monohydrate and add The above solution was ultrasonically stirred for five minutes to obtain an orange-red transparent clear solution, then 7ml oleic acid was added thereto, stirred evenly, the above solution was transferred to the lining of a 100ml p-polyphenyl reactor, and the reactor was put into an oven. Keep the reaction at 220°C for 8h. After the reaction is finished, the reactant is naturally cooled, washed with absolute ethanol for 6 times, centrifuged and dried at 60°C for 8 hours to obtain cesium tungsten bronze nanopowder;

[0071] (2) Add 1g of cesium tungsten bronze nano-powder into 20ml of n-hexane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

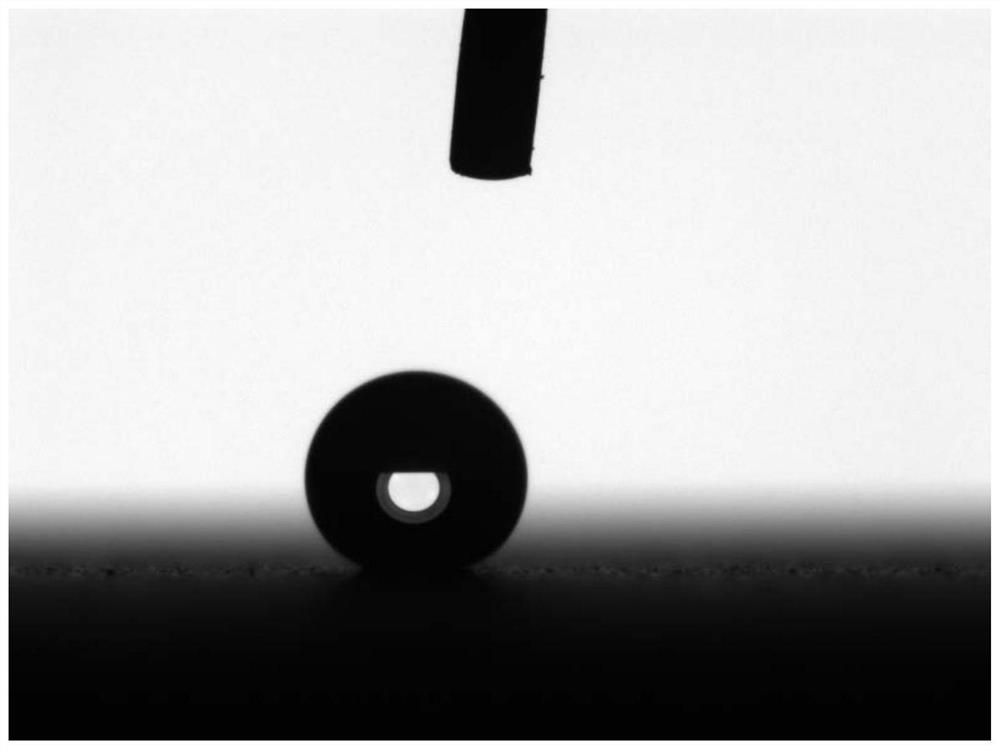

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com