System and process for removing crude and light pyridine

A pyridine and crude removal technology, applied in the crude pyridine removal system and process field, can solve the problems of complex neutralization tank, cumbersome process, short process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

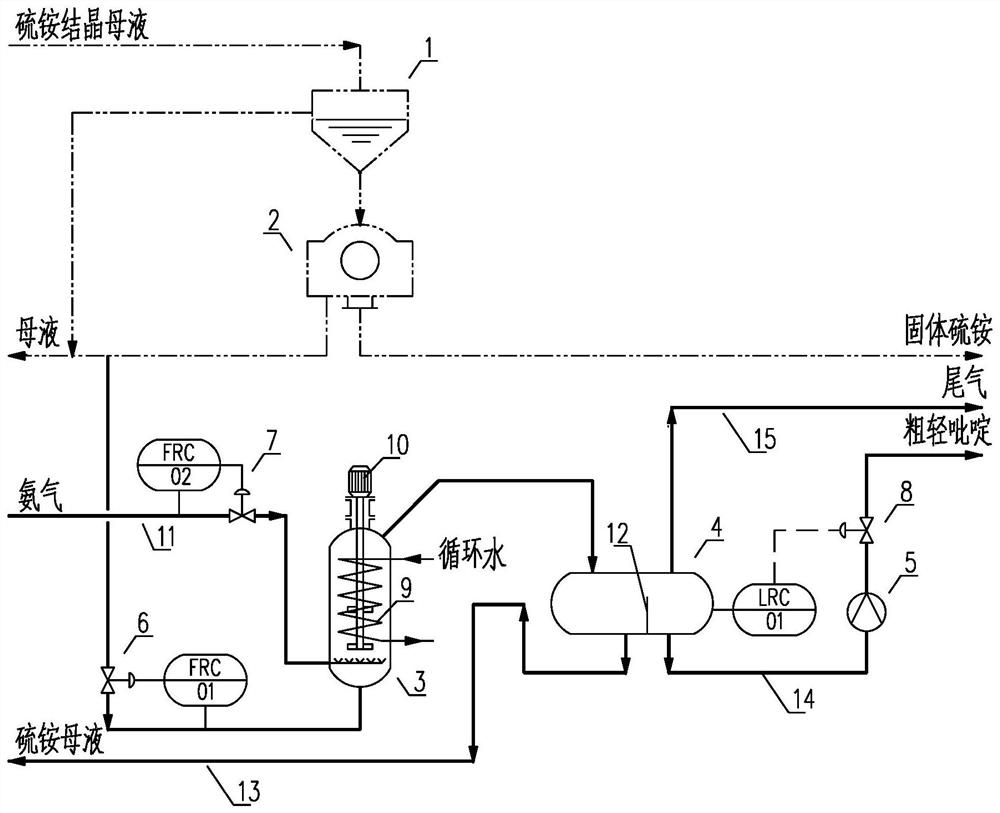

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] like figure 1 As shown, a crude light pyridine removal system includes a crystallization tank 1, a centrifuge 2, a neutralization tank 3 and a mother liquor separation tank 4. The saturator is connected to the top of the crystallization tank 1 through a pipeline, the bottom of the crystallization tank 1 is connected to the top of the centrifuge 2 through a pipeline, the bottom of the centrifuge 2 is connected to the solid ammonium sulfate delivery pipeline, and the bottom of the centrifuge 2 is connected to the saturator through a pipeline.

[0029] A mixer 10 is arranged on the top of the neutralization tank 3, and a circulating water pipeline 9 is arranged inside. The bottom of the centrifuge 2 is connected to the bottom of the neutralization tank 3 through a pipeline, and the pipeline connecting the bottom of the centrifuge 2 and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com