Refining method of methoxyamine hydrochloride

A kind of technology of methoxyamine hydrochloride and refining method, applied in the refining field of methoxyamine hydrochloride, can solve problems such as affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

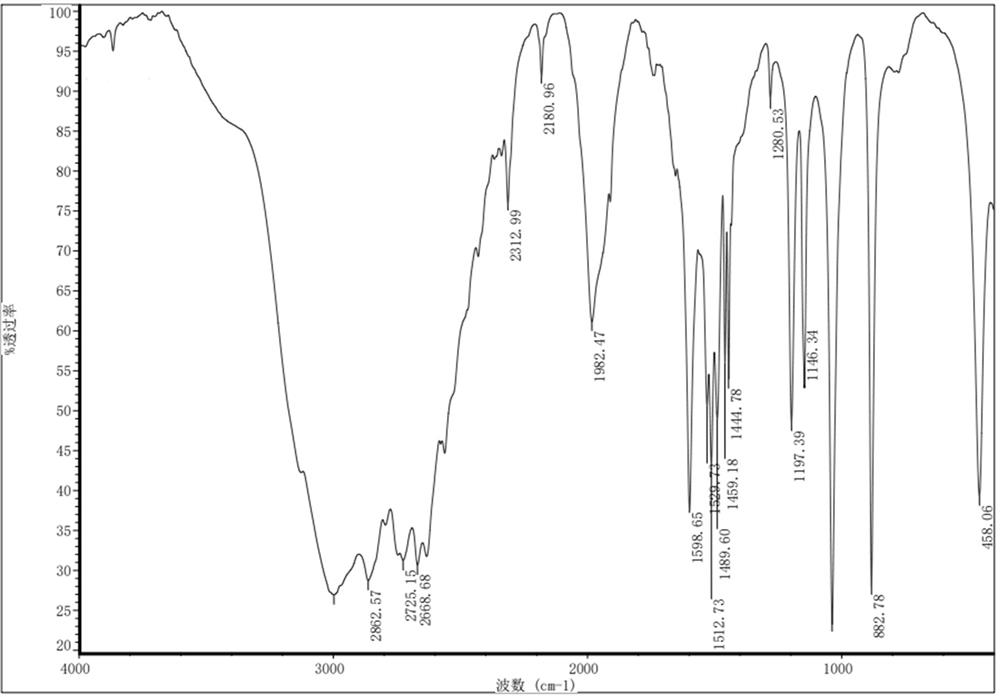

Image

Examples

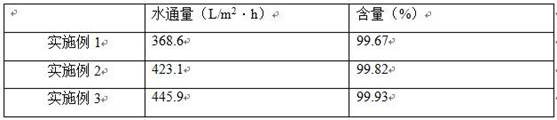

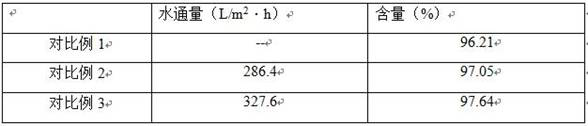

Embodiment 1

[0028] A kind of refining method of methoxyamine hydrochloride, its scheme is:

[0029] Pump the reaction liquid in the 100kg reaction tower kettle to the reboiler for heating and circulation to 50°C through the reaction tower pump, then enter the rectification tower 1 for vacuum rectification reaction, and the distillate flows into the distillation tank of the reaction tower through secondary condensation at the top of the tower , the rectification tower still liquid is pumped into the tower still liquid separator for stratification, the lower layer is methoxyamine hydrochloride solution; then the lower layer methoxyamine hydrochloride solution is pumped into the concentration tower, after concentration The tower circulating pump and the concentration tower reboiler are heated to 60°C and concentrated to 40%, then add 80kg of organic solvent, stir and mix evenly, then cool down to 30°C through a heat exchanger, and then filter through a microporous membrane filter. The obtain...

Embodiment 2

[0038] A kind of refining method of methoxyamine hydrochloride, its scheme is:

[0039]The reaction liquid in the 200kg reaction tower tank is pumped into the reboiler through the reaction tower pump to heat and circulate to 60°C, and then enters the rectification tower 1 for vacuum rectification reaction, and the distillate flows into the distillation tank of the reaction tower through secondary condensation at the top of the tower , the rectification tower still liquid is pumped into the tower still liquid separator for stratification, the lower layer is methoxyamine hydrochloride solution; then the lower layer methoxyamine hydrochloride solution is pumped into the concentration tower, after concentration The tower circulation pump and the reboiler of the concentration tower are heated to 70°C and concentrated to 50%, then add 100kg of organic solvent, stir and mix evenly, then cool down to 35°C through a heat exchanger, and then filter through a microporous membrane filter. ...

Embodiment 3

[0048] A kind of refining method of methoxyamine hydrochloride, its scheme is:

[0049] Pump the reaction liquid in the reactor of 300kg reaction tower to the reboiler for heating and circulation to 80°C through the reaction tower pump, then enter the rectification tower 1 for vacuum rectification reaction, and the distillate flows into the distillation tank of the reaction tower through secondary condensation at the top of the tower , the rectification tower still liquid is pumped into the tower still liquid separator for stratification, the lower layer is methoxyamine hydrochloride solution; then the lower layer methoxyamine hydrochloride solution is pumped into the concentration tower, after concentration The tower circulation pump and the concentration tower reboiler are heated to 80°C and concentrated to 60%, then add 160kg of organic solvent, stir and mix evenly, then cool down to 40°C through a heat exchanger, and then filter through a microporous membrane filter. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com