Synthesis method of high-purity odorless chlorphenesin

A technology for chlorophenesiol and a synthesis method, which is applied in the directions of ether preparation, alkylene oxide preparation of ether, organic chemistry, etc., can solve the problems of incomplete reaction of raw materials in the synthesis process, complex reaction products, potential safety hazards, etc., and achieves no para-chlorine The effect of phenol residue, simple reaction process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

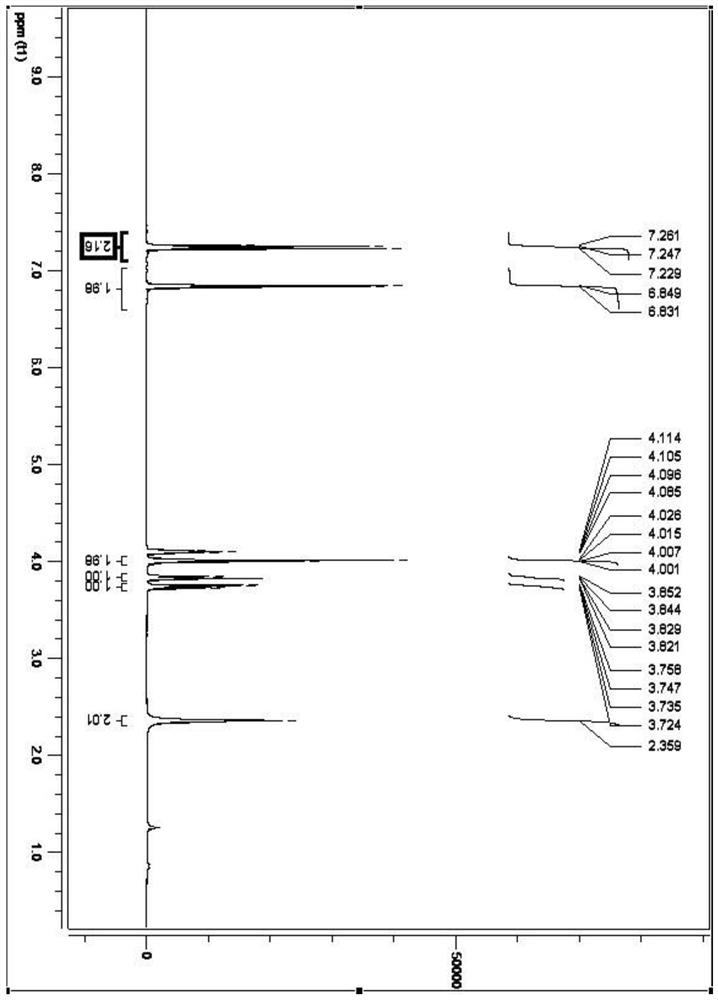

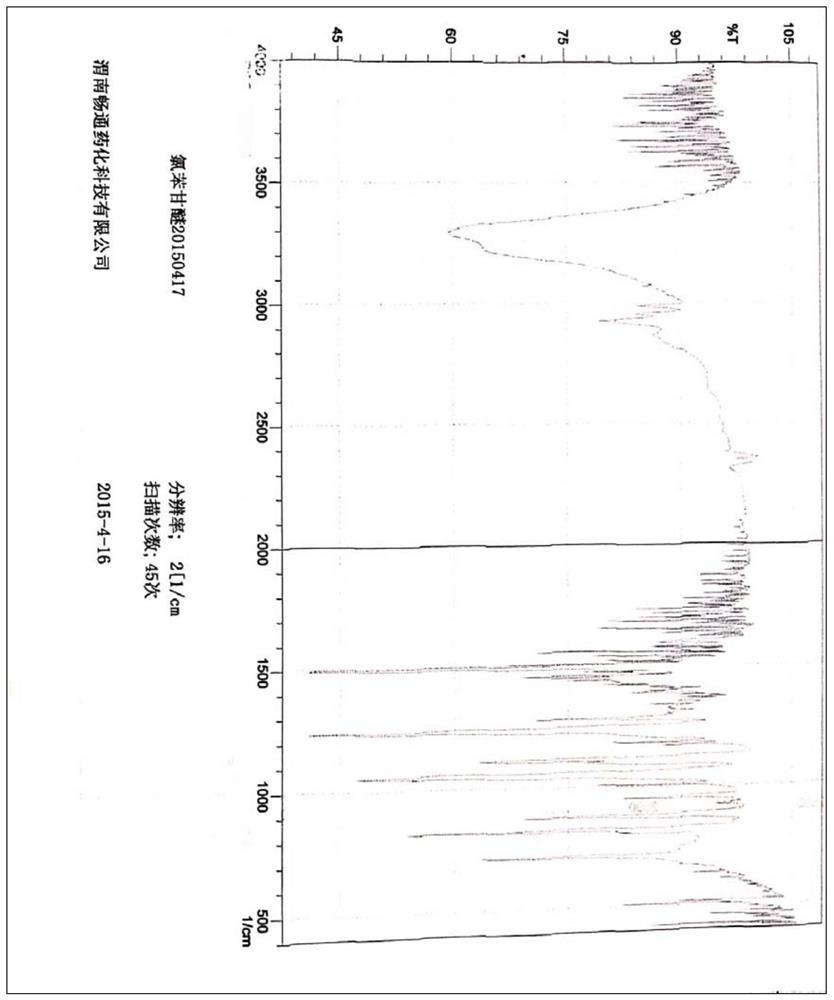

Image

Examples

Embodiment 1

[0037] A kind of high-purity odorless chlorphenesin synthetic method, concrete operation is as follows:

[0038] S1: Put 300kg of purified water, 7.8kg of sodium hydroxide and 250kg of p-chlorophenol into a 1000L reaction tank and stir for 10 minutes;

[0039] S2: Put 1kg of benzyltriethylammonium chloride into the reaction tank and heat to 50°C;

[0040] S3: Slowly drop 150kg of glycidol into the reaction tank at a constant temperature of 50°C;

[0041] S4: After the reaction is finished, let it stand for stratification, the upper layer is the brine layer, and the lower layer is the product layer;

[0042] Put the brine layer into a 200L crystallization bucket and let it stand for crystallization overnight. The clear liquid is concentrated under reduced pressure, and the distilled wastewater is discharged after three-dimensional electrolysis and biochemical treatment up to standard. The concentrated residue is disposed of as hazardous waste.

[0043] The production waste ga...

Embodiment 2

[0047] A kind of high-purity odorless chlorphenesin synthetic method, concrete operation is as follows:

[0048] S1: Put 300kg of purified water, 8.2kg of sodium hydroxide and 250kg of p-chlorophenol into a 1000L reaction tank and stir for 10 minutes;

[0049] S2: Put 2kg of tetrabutylammonium bromide into the reaction tank and heat to 70°C;

[0050] S3: Slowly drop 150kg of glycidol into the reaction tank at a constant temperature of 70°C;

[0051] S4: After the reaction is finished, let it stand for stratification, the upper layer is the brine layer, and the lower layer is the product layer;

[0052] Put the brine layer into a 200L crystallization bucket and let it stand for crystallization overnight. The clear liquid is concentrated under reduced pressure, and the distilled wastewater is discharged after three-dimensional electrolysis and biochemical treatment up to standard. The concentrated residue is disposed of as hazardous waste.

[0053] The production waste gas (incl...

Embodiment 3

[0057] A kind of high-purity odorless chlorphenesin synthetic method, concrete operation is as follows:

[0058] S1: Put 300kg of purified water, 8.5kg of potassium carbonate and 250kg of p-chlorophenol into a 1000L reaction tank and stir for 10 minutes;

[0059] S2: Put 5kg of chain polyethylene glycol into the reaction tank and heat to 70°C;

[0060] S3: Slowly drop 150kg of glycidol into the reaction tank at a constant temperature of 70°C;

[0061] S4: After the reaction is finished, let it stand for stratification, the upper layer is the brine layer, and the lower layer is the product layer;

[0062] Put the brine layer into a 200L crystallization bucket and let it stand for crystallization overnight. The clear liquid is concentrated under reduced pressure, and the distilled wastewater is discharged after three-dimensional electrolysis and biochemical treatment up to standard. The concentrated residue is disposed of as hazardous waste.

[0063] The production waste gas (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com