Method for preparing organic fertilizer by utilizing dredged sludge of rivers and lakes

A technology for dredging sludge and organic fertilizer, which is applied in the fields of organic fertilizer, sewage/sludge fertilizer, biological organic part treatment, etc., can solve the problems of long fermentation period, low fermentation efficiency and high time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

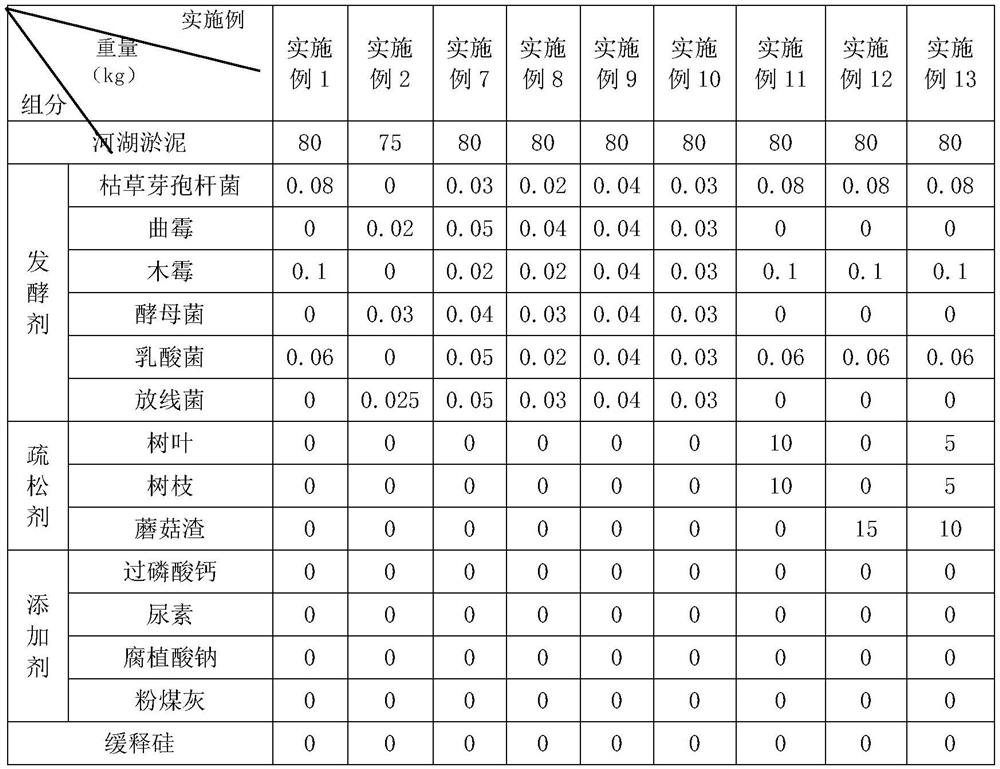

[0042] A kind of organic fertilizer that utilizes river and lake dredging silt to make, the concrete components that comprise and weight are as shown in table 2, are made by following steps:

[0043] S1: dewatering and screening the river and lake sludge, and pressing and filtering with a filter press to obtain pretreated river and lake sludge. The moisture content of the pretreated river and lake sludge is 18%;

[0044] S2: Carry out high-temperature sterilization of the treated river and lake sludge in a high-temperature furnace, the sterilization temperature is 150° C., and the sterilization time is 40 minutes to obtain the sterilized river and lake sludge;

[0045] S3: mixing and stirring the sterilized river and lake silt with deionized water, the stirring speed is 800r / min, and after stirring evenly, the river and lake silt with a moisture content of 70% is obtained;

[0046] S4: Mix and stir Bacillus subtilis, Trichoderma, and lactic acid bacteria at a stirring speed of...

Embodiment 2

[0048] Embodiment 2: a kind of organic fertilizer that utilizes river and lake dredging silt to make, and the difference of embodiment 1 is that concrete component and weight are different, and included concrete component and weight are as shown in table 2, comprise the following steps:

[0049] S1: dewatering and screening the river and lake sludge, and pressing and filtering with a filter press to obtain pretreated river and lake sludge. The moisture content of the pretreated river and lake sludge is 18%;

[0050] S2: Carry out high-temperature sterilization of the treated river and lake sludge in a high-temperature furnace, the sterilization temperature is 280° C., and the sterilization time is 20 minutes to obtain the sterilized river and lake sludge;

[0051] S3: mixing and stirring the sterilized river and lake silt with deionized water at a stirring speed of 800r / min, and obtaining river and lake silt with a water content of 80% after stirring evenly;

[0052] S4: Mix asp...

Embodiment 3

[0053] Embodiment 3: a kind of organic fertilizer that utilizes river and lake dredging silt to make, and the difference of embodiment 1 is, the water content of the river and lake silt after pretreatment in step S1 is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com