Novel building mortar taking iron tailing powder as raw material and preparation method of novel building mortar

A technology of iron tailings powder and construction sand, applied in the field of building materials, can solve the problems of waste iron tailings accumulation and ineffective recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

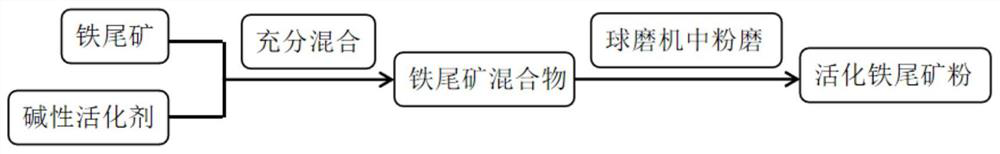

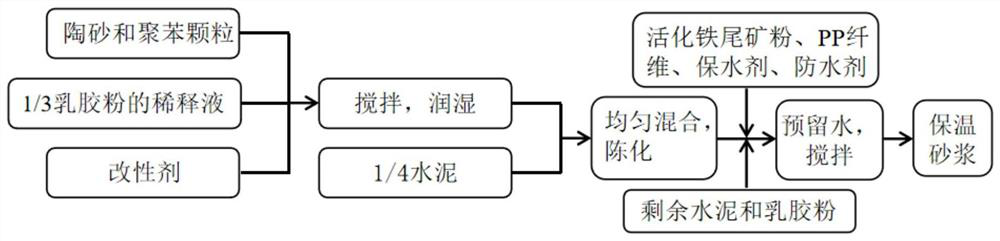

[0054] The preparation method of construction mortar of the present invention specifically comprises the following steps:

[0055] Step 1. Take the weight of the required raw materials respectively according to the test proportion and dosage, and weigh them for future use;

[0056] Step 2: Using water-diluted modifier and part of VAE latex powder to fully wet the polystyrene particles and ceramic sand particles, then put in cement, mix evenly, and perform aging pretreatment;

[0057] Step 3. Then add the remaining VAE latex powder and cement, activated iron tailings powder, fiber, water retaining agent and waterproofing agent, add reserved water while stirring, and fully stir for 3 to 5 minutes.

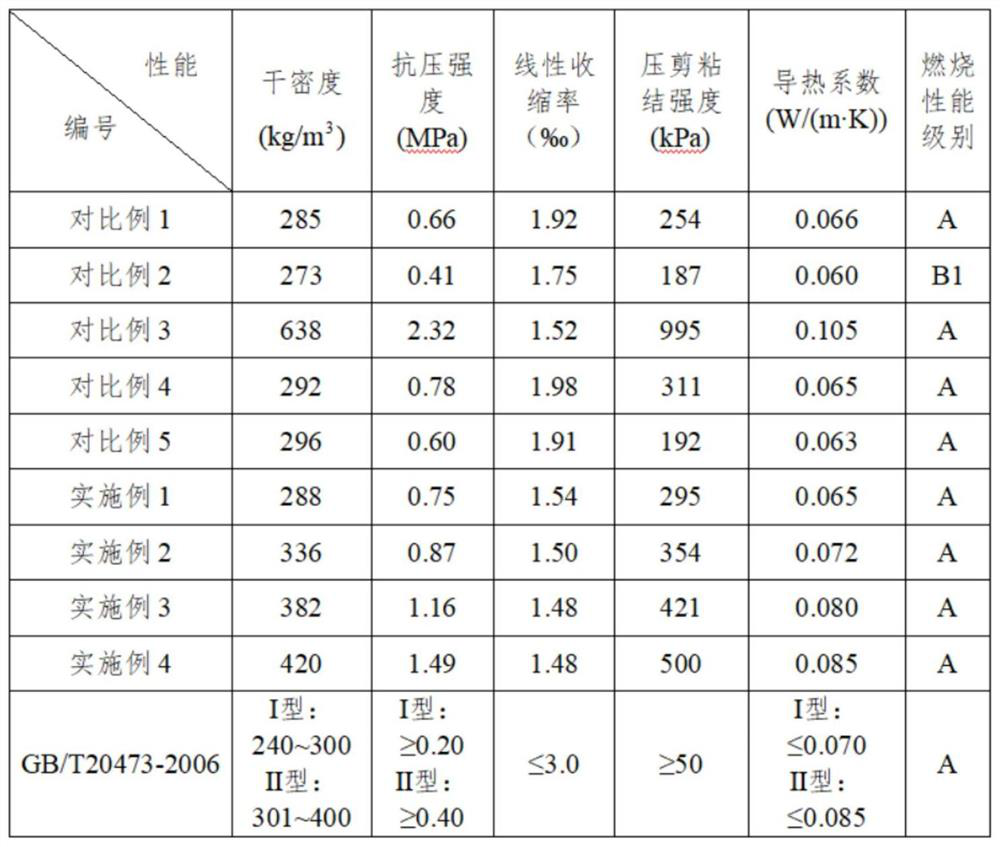

[0058] The present invention makes full use of the abandoned iron tailings, and prepares a new type of thermal insulation mortar by using the waste after mineral processing and organic-inorganic composite binary aggregate, and mixes an appropriate amount of fiber, latex powder and ot...

Embodiment 1

[0061] Each material used in the preparation was weighed according to the following metering fraction, wherein the total volume of ceramic sand particles (L): the total volume of polystyrene particles (L) = 1:9. That is, ceramic sand particles 8.0%, polystyrene particles 1.0%, activated iron tailings powder 14.0%, ordinary Portland cement 30.0%, PP fiber 0.35%, VAE latex powder 1.55%, modifier 0.1%, cellulose ether 0.35%, waterproofing agent 1.55%, and the rest is water; then use water-diluted modifier and 1 / 3 VAE latex powder to fully wet the polystyrene particles and ceramic sand particles, and then add 1 / 4 amount of Cement, mix evenly, and carry out aging pretreatment; finally, mix and stir the pretreated thermal insulation aggregate with the remaining VAE latex powder and cement, activated iron tailings powder, fiber, water-retaining agent and waterproof agent, Stirring is continued for another 3 minutes to prepare thermal insulation mortar. When activating the iron tailin...

Embodiment 2

[0063] Weigh each material used in the preparation according to the following metering fractions, the total volume of ceramic sand particles (L): the total volume of polystyrene particles (L) = 1:4. That is, ceramic sand particles 16.2%, polystyrene particles 0.75%, activated iron tailings powder 13.8%, ordinary portland cement 29.0%, PP fiber 0.27%, VAE latex powder 1.39%, modifier 0.09%, cellulose ether 0.27%, waterproofing agent 1.39%, and the rest is water. Then prepare thermal insulation mortar according to the preparation method of Example 1. When activating the iron tailings, the content of the active activator is controlled to be 1.2%, and the co-grinding time is controlled to be 0.8h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com