Self-compacting concrete based on ultrasonic concussion technology and preparation method of self-compacting concrete

A self-compacting concrete, ultrasonic vibration technology, applied in the field of concrete, can solve the problems of reducing the strength of concrete, decreasing the strength of concrete, increasing the friction force of fibers, etc., and achieving the effect of wide source and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The above-mentioned preparation method of self-compacting concrete based on ultrasonic vibration technology comprises the following steps:

[0056] (1) According to the weight, the above raw materials are divided into four groups, the first group is 0.006-0.018 parts of sisal fiber, the second group is 0.0012-0.0036 parts of silicon dioxide, the third group is 0.840 parts of water and high-efficiency water-reducing The fourth group is 1 part of ordinary portland cement, 0.78 part of primary fly ash, 0.32 part of stone powder, 1.68 part of gravel, and 0.84 part of standard sand.

[0057] (2) Put the first group of samples into the sodium hydroxide solution and let them stand for 0.25 hours, then wash them with water and dry them at 80°C to remove surface impurities.

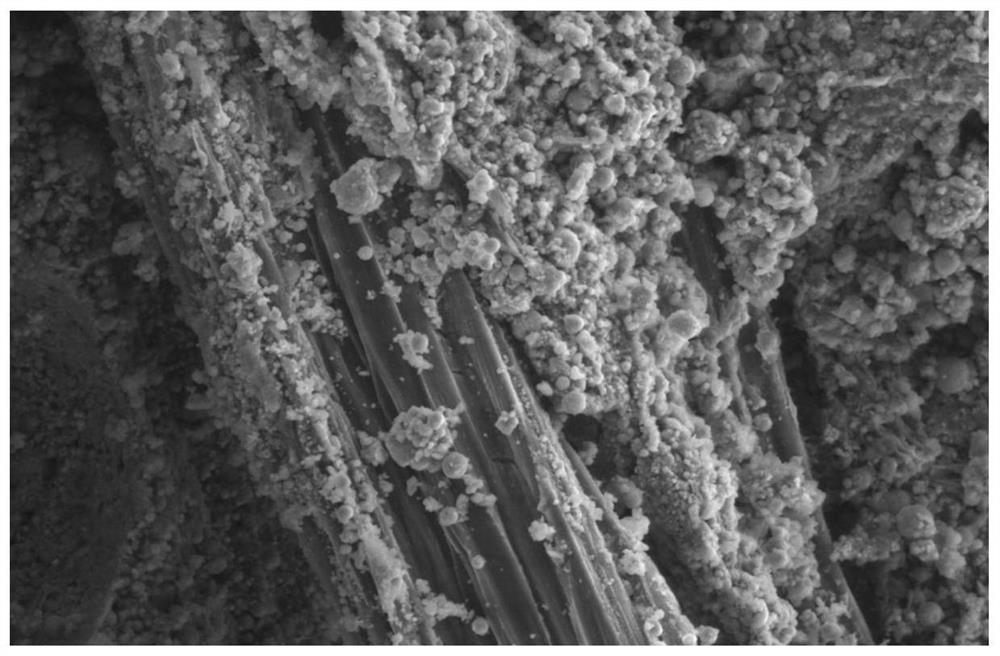

[0058] (3) Add the second group of samples into 300 milliliters of ethanol solution to make a suspension, and put the suspension device into an ultrasonic oscillator, and perform vibration treatment with a ...

Embodiment 1

[0100] The present embodiment self-compacting concrete, by weight parts, the composition and content of concrete are respectively:

[0101] Ordinary Portland cement: 1 part

[0102] Primary fly ash: 0.78 parts

[0103]Stones: 1.68 parts

[0104] Standard sand: 0.84 parts

[0105] Stone powder: 0.32 parts

[0106] Superplasticizer: 0.168 parts

[0107] Sisal fiber: 0.006 parts

[0108] Nano silicon dioxide: 0.0012 parts

[0109] Water: 0.840 parts

[0110] Coupling agent: 0.00012 parts

[0111] Dispersant: 0.0012 parts

[0112] In this embodiment, the stone powder is silica powder.

Embodiment 2

[0114] On the basis of embodiment 1, increase the add-on of sisal fiber and nano silicon dioxide, the number of parts of sisal fiber is 0.012 part. The part number of silica is 0.0024 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com