System and method for combined treatment and utilization of various solid wastes

A technology for solid waste and materials, applied in the fields of chemical industry, environmental protection, and energy, which can solve the problems of high disposal cost, difficult disposal of light materials, and small amount of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

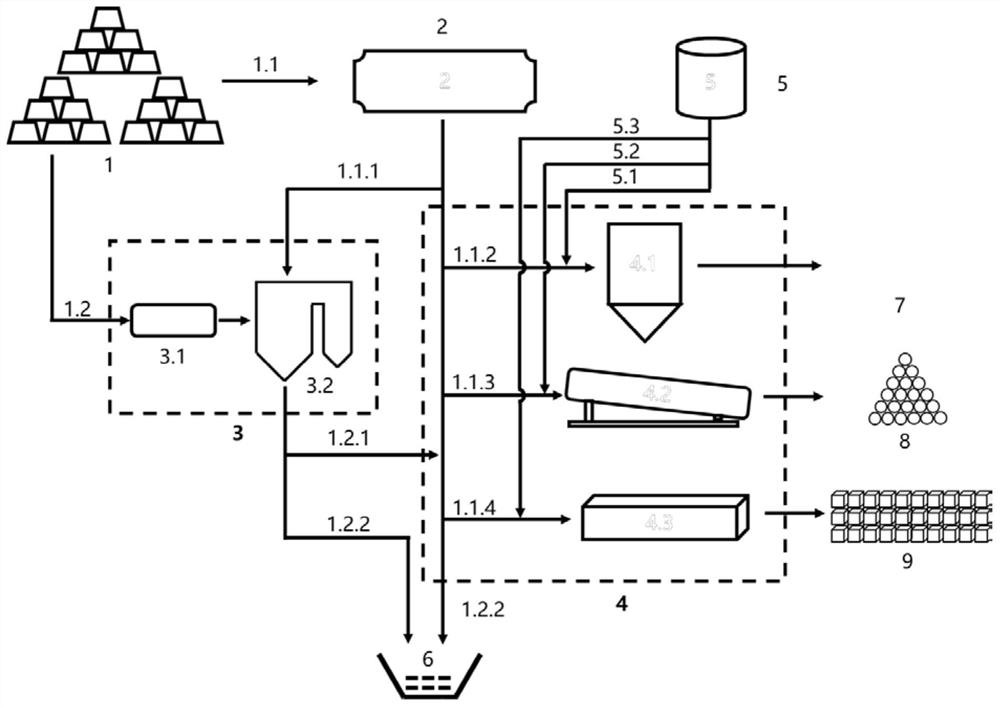

[0034] refer to figure 1 As shown: a system for joint disposal and utilization of various solid wastes of the present invention, including a solid waste storage module 1, a sorting and crushing module 2, a drying and incineration module 3, a resource utilization module 4, a curing agent configuration module 5 and a harmless Landfill module 6; resource products include cement mortar 7, ceramsite 8 and building materials 9; the material outlet of the solid waste storage module 1 is connected with the materials of the sorting and crushing module 2 and the drying and incineration module 3 respectively through the first conveying device The inlet is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com