Universal thermosetting alcohol-free fountain solution and preparation method thereof

A technology free of alcohol and fountain solution, applied in the field of fountain solution, which can solve problems such as damage to rubber rollers, influence of ink gloss, and environmental pollution caused by isopropanol emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

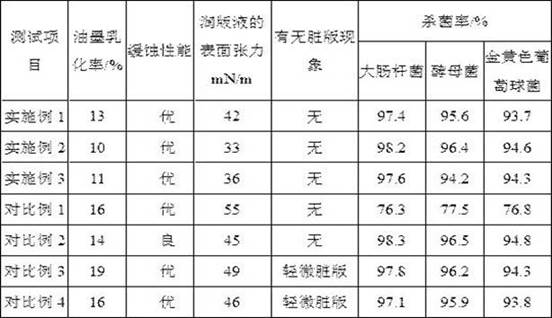

Examples

Embodiment 1

[0031] A all-round thermos well-free alcoholic solution, which consists of 85 parts of magnetically activated water, sodium hydrogen phosphate, 4.0 parts of sodium hydrogen phosphate, 8 copies of citric acid, 2 carboxyail Cellulose, 1.3 parts fat alcohol polyoxyethylene ether, 3 part glycerol, 1.8 parts plant base cleaner, 1.2 servicing, 0.5 sterilizing agent, 2.0 parts of the regulation surface active agent, 1.5 partial antifoaming agent and 1.8 parts wetting agent.

[0032] The preparation method of the plant base cleaner includes the following steps:

[0033] I, use water to clean the soap grass after cleaning into the drying equipment for drying treatment, remove the dried soap grass, and the resulting particle size is 300 mesh micropipestrap, spare;

[0034] II, the above-mentioned soap grass micropowder is put into extraction equipment, and the extraction equipment is added to the extraction equipment 8 times the extraction liquid, the mixture obtained in the extraction equi...

Embodiment 2

[0046] The moisturizing liquid and the preparation method provided in this example are substantially the same as those of the first embodiment, and the main difference is:

[0047] A all-round thermos well-free alcohol-free version of the oil, the moisturizing liquid consists of 95 parts of magnetically activated water, 12 sodium hydrogen phosphate, 5.5 parts sodium sodium sodium, 10 copies of citric acid, 4 parts of carboxyail Cylinder, 1.5 parts fat alcohol polyoxyethylene ether, 4 parts of glycerol, 2.5 parts of plant-based finished lotion, 1.6-parts of function auxiliaries, 0.8 sterilization, 2.6 parts of the regulatory surfactant, 1.8 parts of antifoaming agent and 2.2 parts wetting agent.

[0048] The preparation method of the plant base cleaner includes the following steps:

[0049] I, use water to clean the soap grass after cleaning, transfer to the drying equipment for drying treatment, remove the dried soap grass, and paste the grinding treatment; the resulting particle ...

Embodiment 3

[0061] The moisturizing liquid and the preparation method provided in this example are substantially the same as those of the first embodiment, and the main difference is:

[0062] A fully-intensive thermos-free alcohol-free version of the oil, the moisturizing liquid consists of 100 parts of magnetically activated water, 14 sodium hydrogen phosphate, 6.5 sodium sodium sodium sodium, 12 copies, 6 servility Cylinder, 1.8 parts of fat alcohol polyoxyethylene ether, 6 parts of glycerol, 4.0 parts plant base cleaner, 2.0 function auxiliaries, 1.0 fungicides, 3.2 parts of the regulation surface active agent, 2.2 defoamers and 2.5 parts wetting agent.

[0063] The preparation method of the plant base cleaner includes the following steps:

[0064] I, use water to clean the soap grass after cleaning into the drying equipment to carry out the drying equipment, remove the dry soap, and the resulting particle size is 500 destination to save, spare;

[0065] II, the above-mentioned soap grass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com