Novel underneath type hydraulic machine

A hydraulic press, a new type of technology, applied in the field of hydraulic presses, can solve the problems of inconvenient assembly of the lifting height, shortening of the active power cylinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

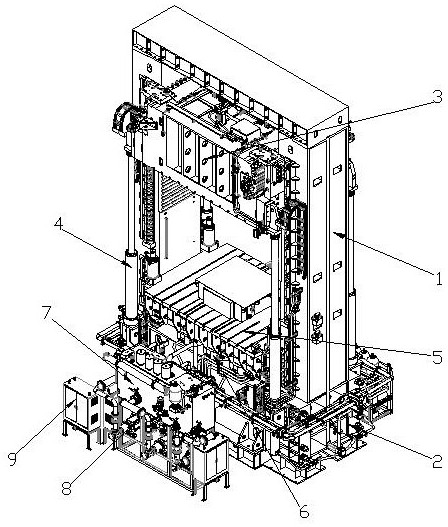

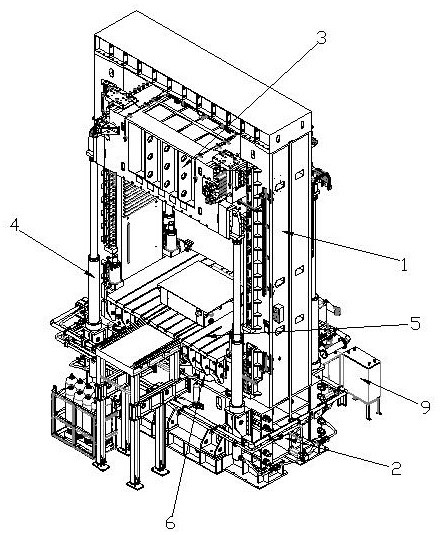

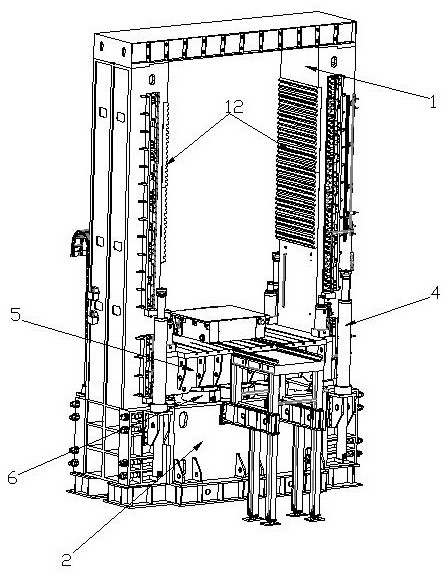

[0051] The content, characteristics and principles of the present invention will be further described below in conjunction with the accompanying drawings. The following descriptions are only examples, not limitations of the present invention.

[0052] As shown in the figure, the present invention is a new type of undermounted hydraulic machine, which includes a column frame 1, a lower beam frame 2 arranged at the bottom of the column frame 1, and a movable upper beam 3 arranged on the column frame 1;

[0053] The four end corners of the lower beam frame 2 corresponding to the movable upper beam 3 are respectively vertically fixed with lifting cylinders 4 for pushing the movable upper beam 3 up and down, and the bottom end angles of the movable upper beam 3 are respectively connected to the corresponding The lifting cylinder 4 is connected;

[0054] The corners of the bottom of the movable upper beam 3 are respectively provided with support seats for assembling and connecting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com