Fabricated connecting structure and building component fabrication method

A connecting structure and prefabricated technology, which is applied in the direction of building components, building structures, protected buildings/shelters, etc., can solve the problems of inconvenient assembly of prefabricated beams and prefabricated walls, and achieve inconvenient assembly and positioning accuracy High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

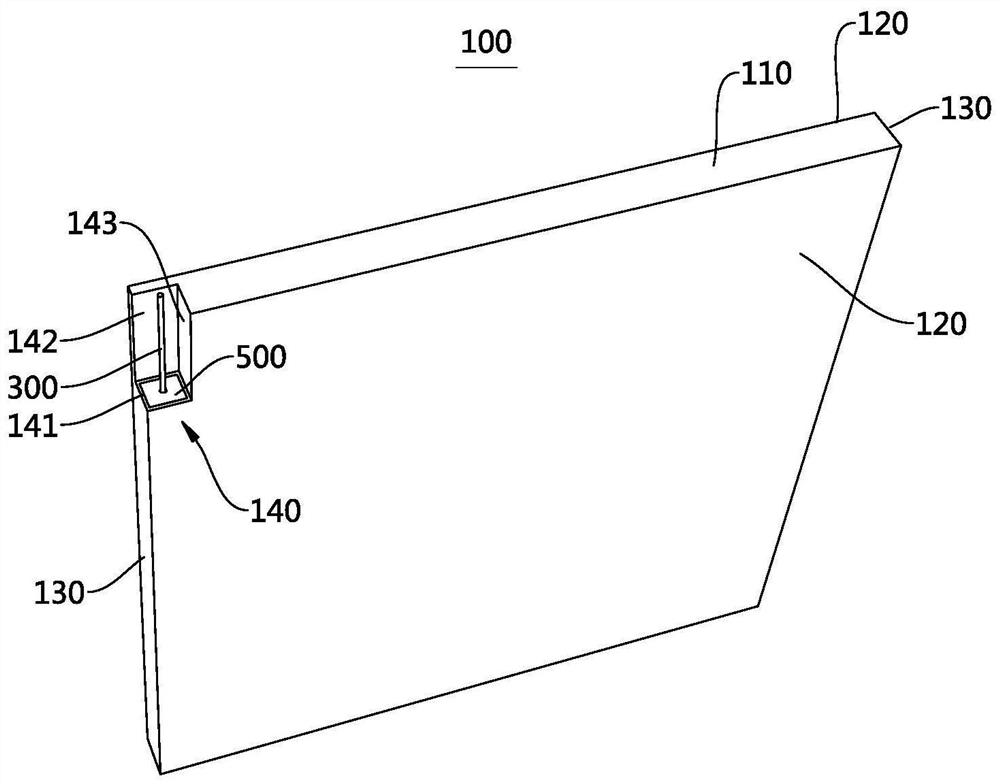

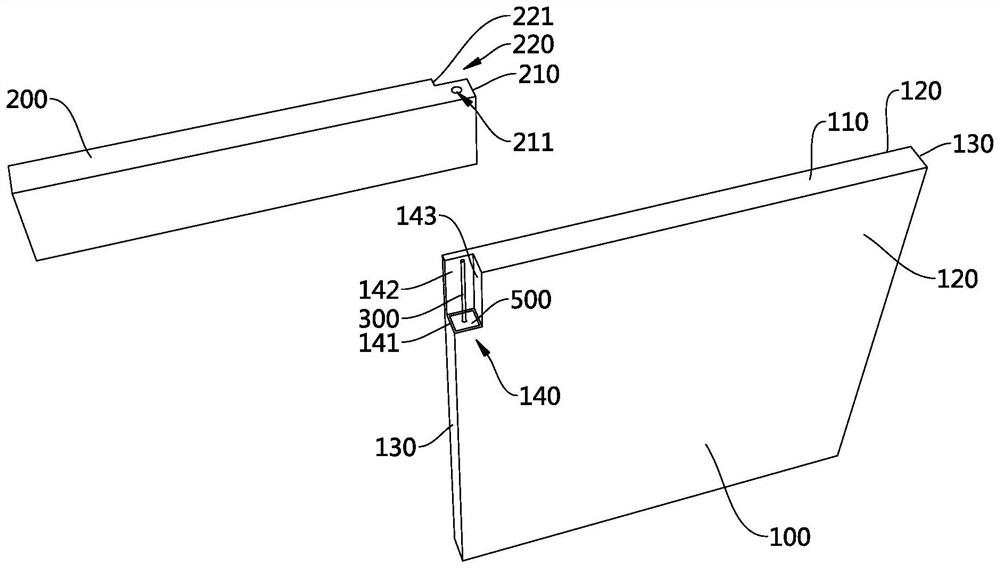

[0053] This embodiment provides a prefabricated connection structure, which includes prefabricated beams 200, prefabricated walls 100 and reserved ribs 300. The prefabricated connection structure is easy to assemble and has high assembly accuracy.

[0054] Such as figure 1 , the upper corner of the prefabricated wall body 100 is provided with a notch 140 . The so-called notch 140 refers to making the upper corner of the prefabricated wall body 100 from a male corner into a structure similar to a female corner.

[0055] A reserved rib 300 is provided at the bottom of the notch 140 , one end of the reserved rib 300 extends into the prefabricated wall 100 for fixing, and the other end extends upward from the bottom of the notch 140 .

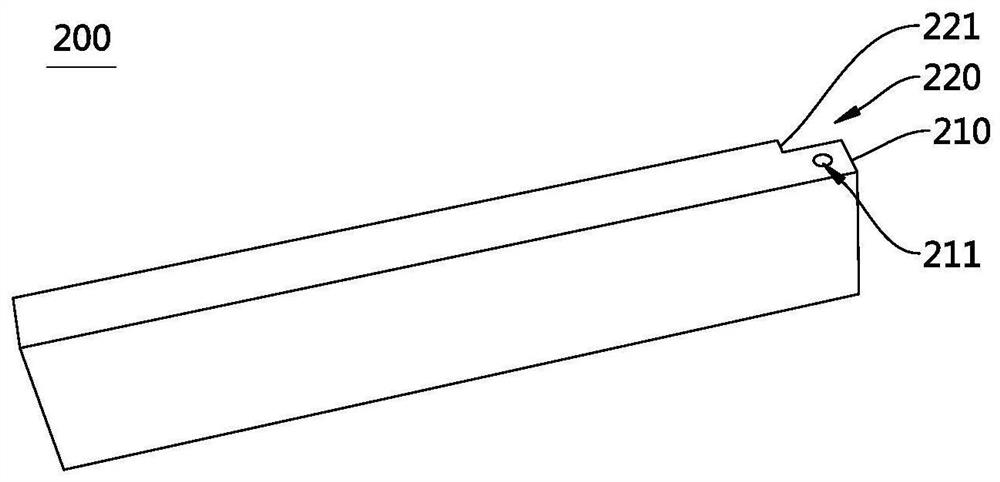

[0056] Precast Beam 200 AS figure 2 As shown, a protrusion 210 is formed at one end thereof. The so-called protrusion 210 refers to a protrusion protruding horizontally from the beam end surface 130 of the prefabricated beam 200 . A through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com