Tightening mechanism for wafer cleavage, film tightening assembly and film tightening method

A stretch film and cleavage technology, applied in the field of tension mechanism of wafer cleavage, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

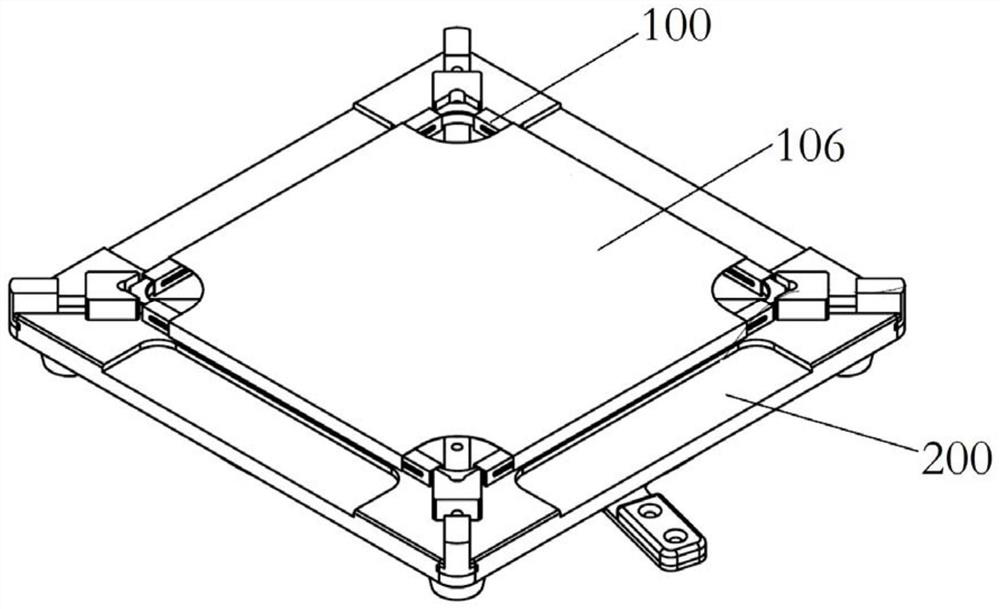

[0060] The flirtraine assembly provided in this embodiment, such as figure 1 As shown, the tensioning mechanism 200 and the banditer frame 100 are included; the tensioning mechanism 200 and the sliding frame 100 are used in conjunction, and the film 106 is disposed in the sliding frame in the process of the wafer. 100 on 100;

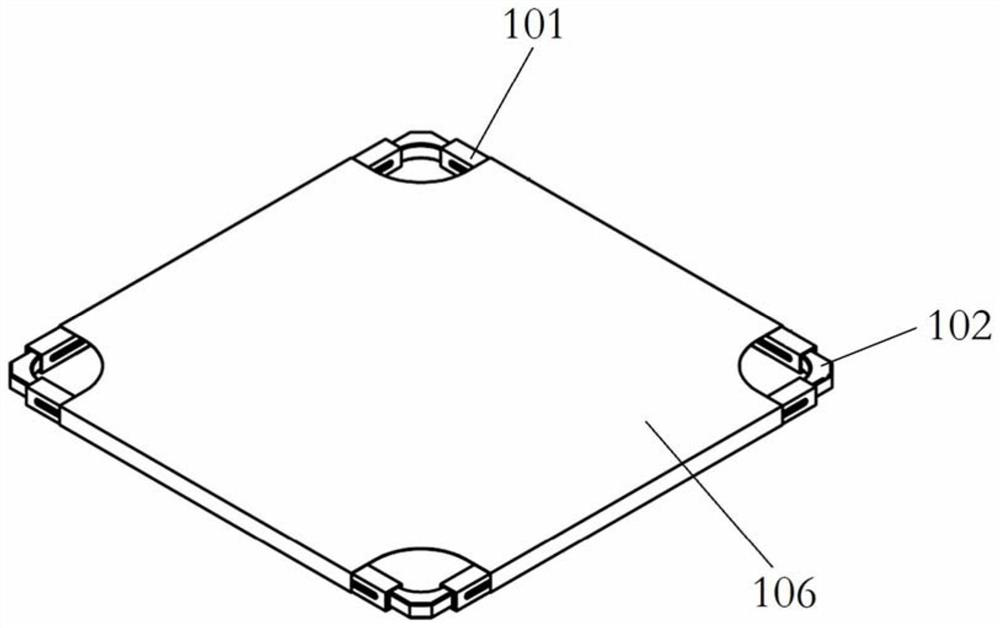

[0061] like figure 2 As shown, the sliding frame 100 has a rectangular shape, has a four-sliding film tube 101, and the four sluts 101 constitute the four sides of the stretch film 100, and the flungeon 101 has a cavity;

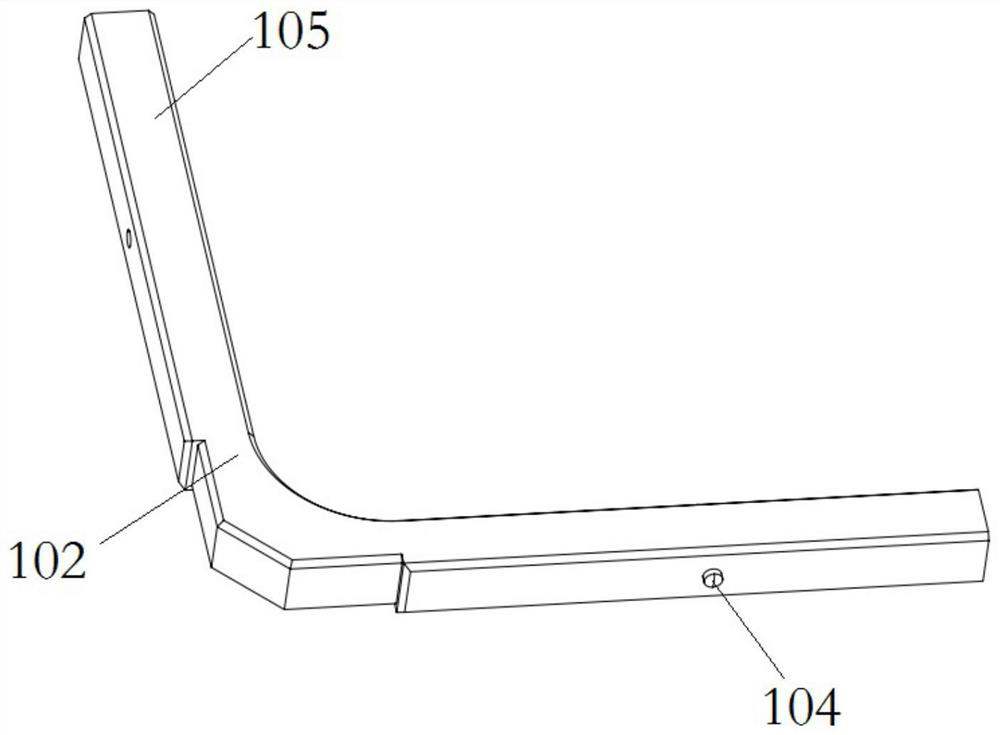

[0062] like image 3 As shown, the adjacent end slides in the adjacent end slide inserted with a tension angle 102, the tension angle 102 is "L" type, and the two ends are suitable for sliding to the sliding tube. Insert 105 in the cavity of 101;

[0063] like Figure 4 , 5 As shown, a finiterating device is provided between the tensioning angle 102 and the sliding tube 101; the limit device includes a limit slot 103 disposed on the side wa...

Embodiment 2

[0076] The flunter method according to the present embodiment, the flirtave assembly of Example 1, including the steps of:

[0077] The scratch film 106 is placed, and the four corners of the rectangular scrubbing film 106 are disconnected to avoid the position of the top block 205 on the base 201, and the cutting film 106 will be cut. The front surface of the base 201 is laid;

[0078] The slacete frame 100 is placed such that the second end 209 of the driving groove 207 on the turntable 206 is located at the position of the drive shaft 204, that is, the top tension block 205 is in the second state away from the center of the base 201; the sliding tube of the slope frame 100 The outer surface of 101 is pasted on the double-sided adhesive, press the tension angle 102, placed on the base 201, so that a tension angle 102 is in contact with a top block 205;

[0079] The mobile handle 210 causes the turntable 206 to rotate, so that the drive shaft 204 also moves, the drive shaft 204 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com