Soilless culture device and soilless culture method

A soilless cultivation and fog cultivation technology, applied in the field of agriculture, can solve problems such as slow development, high labor costs, and failure to meet the needs of agricultural development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

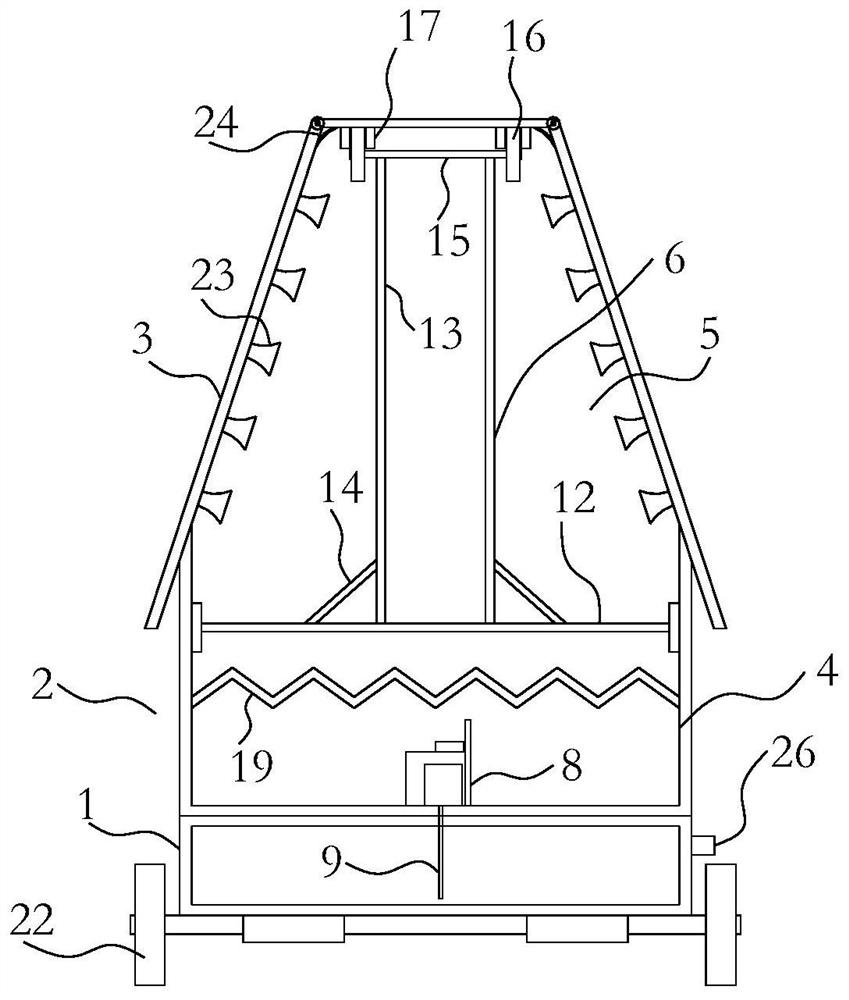

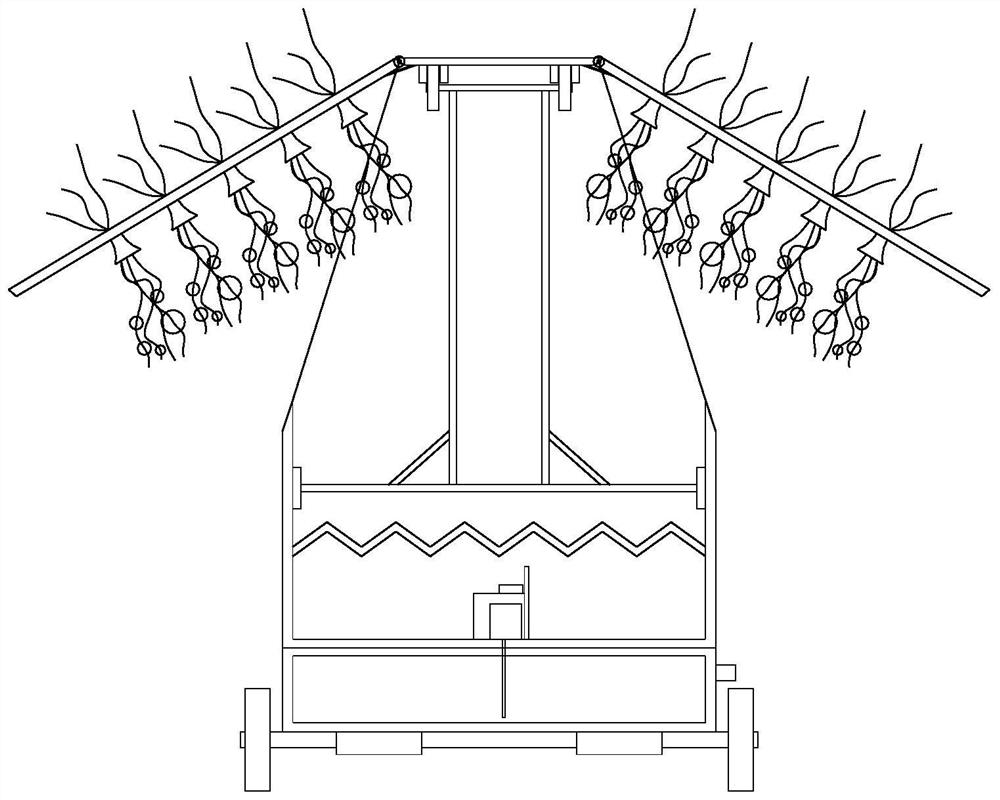

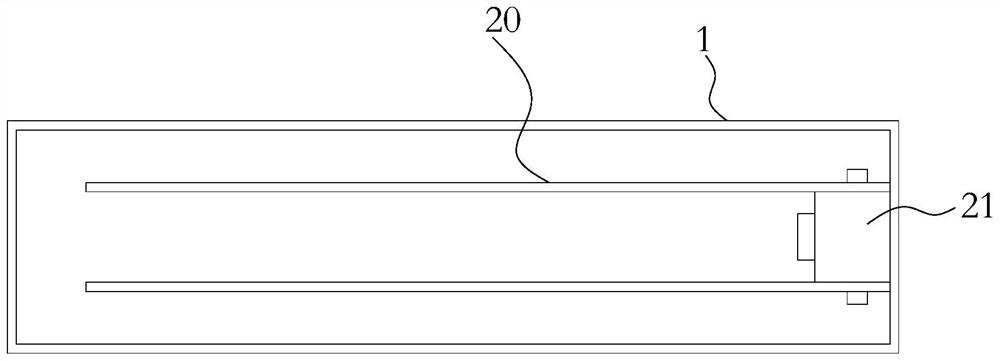

[0032] Such as Figure 1-7 As shown, a soilless cultivation device includes three modules: a liquid storage tank 1, a support tank 2 fixedly arranged above the liquid storage tank 1, and a planting plate 3 built on the support tank 2, and each module is separately Processing, transportation; assembly and use on site. The liquid storage tank 1 is used to store the culture medium, and the side wall of the liquid storage tank 1 is provided with a liquid filling port 26 and the bottom is provided with a liquid discharge port. It is roughly in the shape of a flat cuboid, and its length is specifically designed according to the space of the greenhouse. Its width is generally between 2-2.5m, and it is integrally injection-molded with plastic materials. It is light in weight, low in cost, and has excellent sealing performance. The support tank 2 is arranged above the liquid storage tank 1, and is used for installing the planting plate 3, and the planting plate 3 is laid on the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com