Movable and turnover mold for construction site

A construction site and mold technology, applied in the field of movable and turnable molds, can solve the problems of complex assembly structure, time-consuming and laborious construction, low utilization rate of template, and achieve high utilization rate of template, high utilization rate, simple and reliable assembly structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

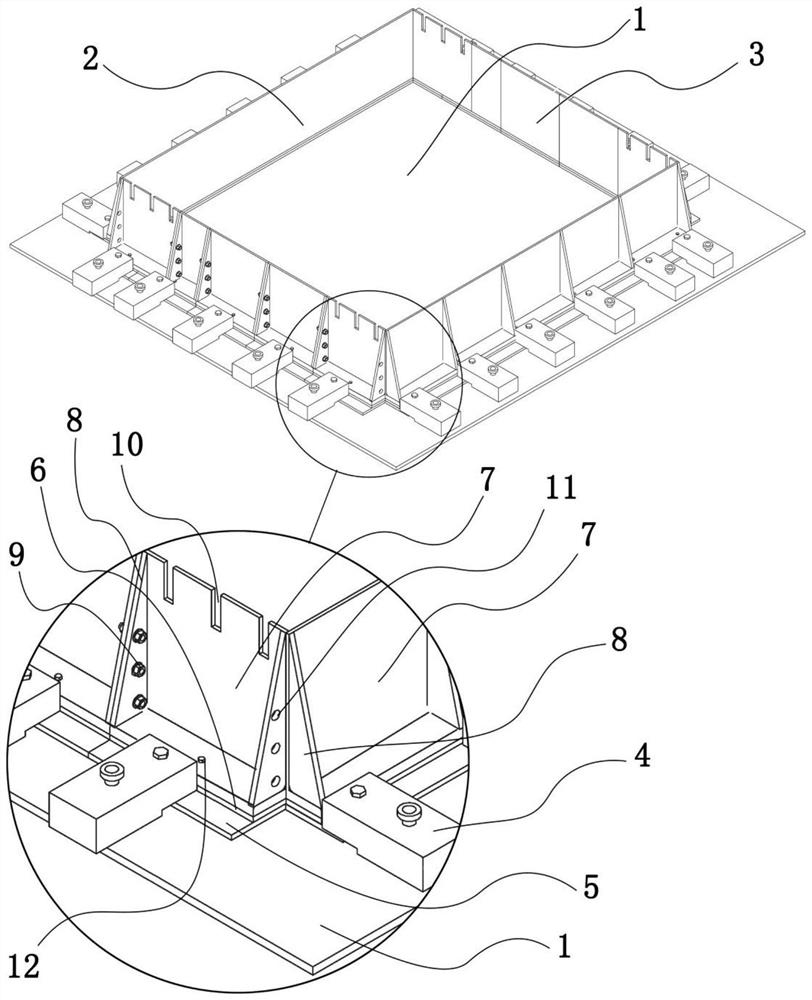

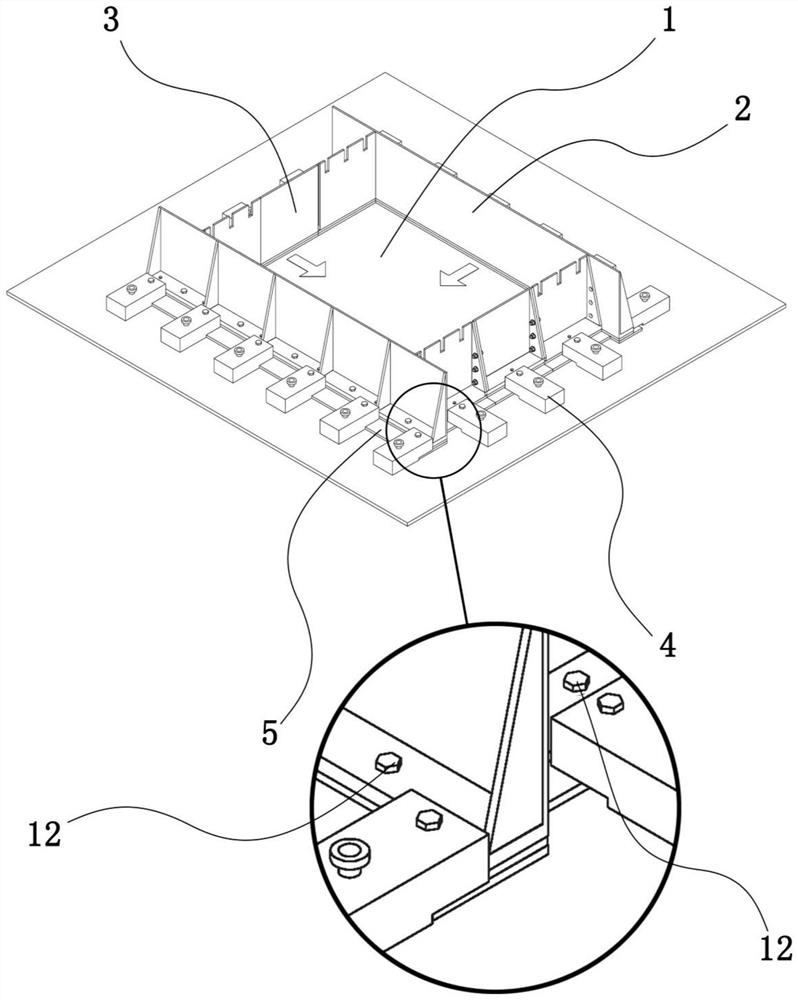

[0026] Embodiment 1 of the present invention, such as figure 1 As shown, a movable and revolvable mold for the construction site includes a bottom mold 1, two long side molds 2 fixed on the bottom mold 1 that are relatively spaced apart, fixed on the bottom mold 1 and Two groups of short side molds 3 or short side molds 3 combined with two groups of symmetrically spaced short side molds 3 that are closed and connected to the two ends of the long side mold 2, and a fixed backing plate 5 fixed to the long side mold 2 or short side mold 3 are used It is used to compress and fix the fixed backing plate 5 and magnetically adsorb a plurality of fixed magnetic boxes 4 on the bottom mold 1, and to fix the long side mold 2 or short side mold 3 and the fixed backing plate 5 The fastening bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com