Construction process for casting large-tonnage box beam in site by support pier method

A technology of cast-in-place beams and piers, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high construction cost, long construction period, large amount of steel such as support formwork, etc., and achieve low construction cost and material consumption. The effect of small size and easy disassembly and assembly of buttresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

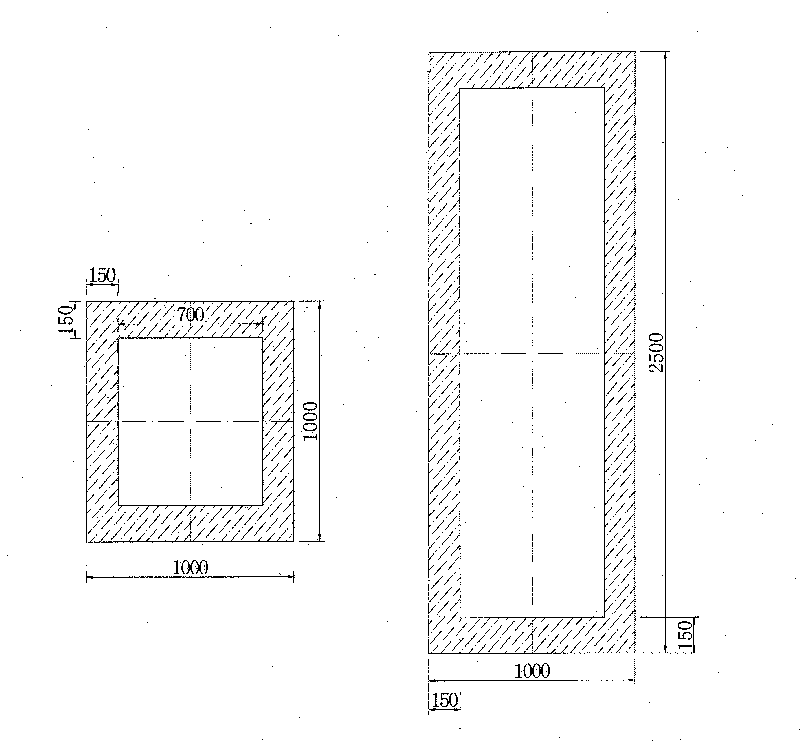

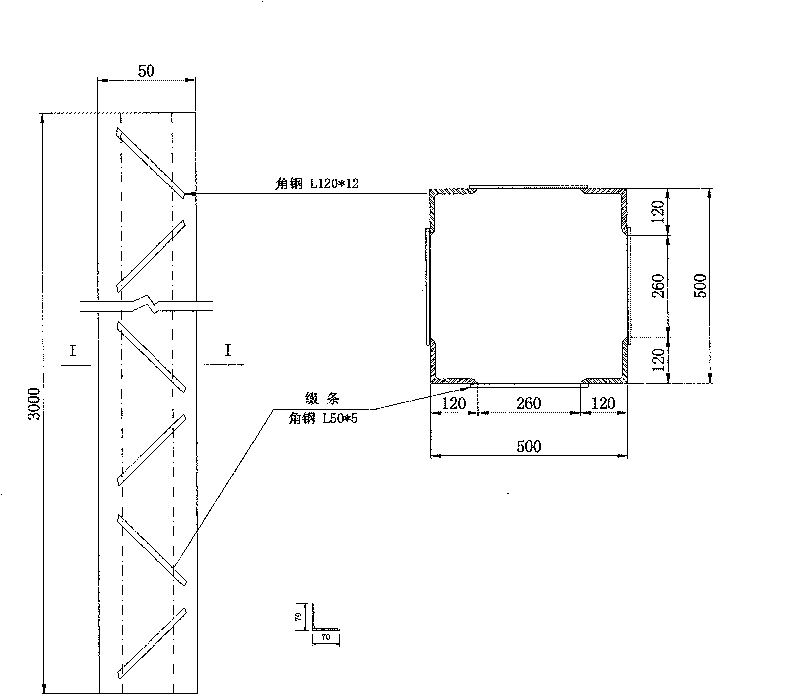

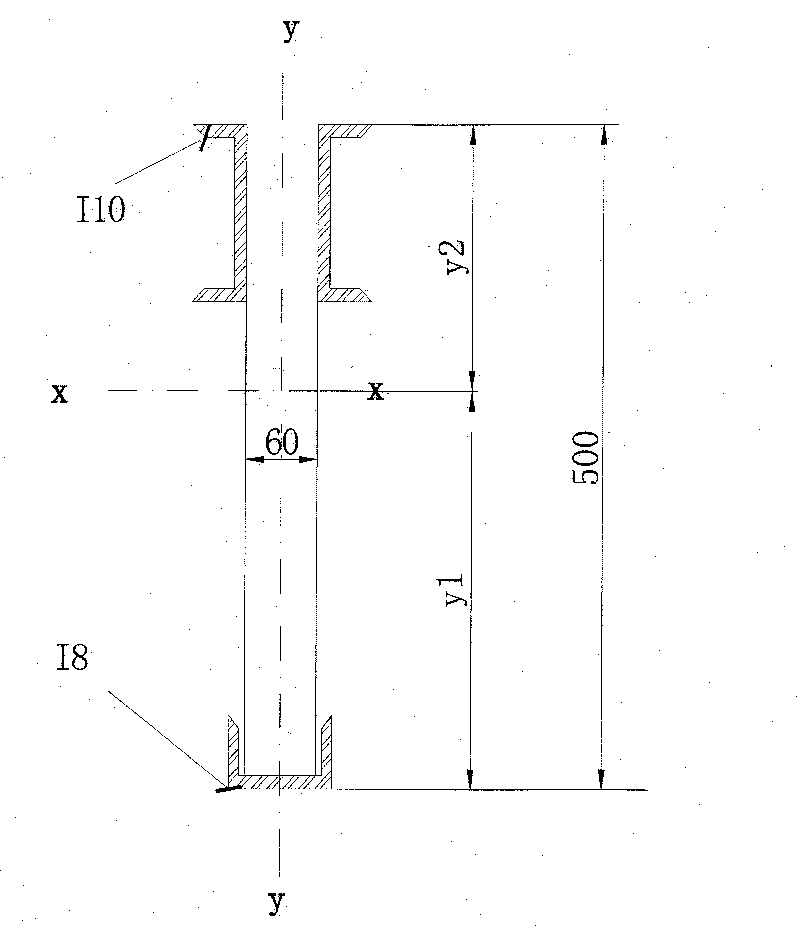

[0021] The Zhengxi Passenger Dedicated Line starts from Zhengzhou City in the east, passes through Luoyang City, Sanmenxia City, and Weinan City in the west, ends in Xi'an City in the west, passes through Henan and Shaanxi provinces, passes through Zhengzhou, Luoyang, and Xi'an railway hubs, and connects the Beijing-Guangzhou Passageway and Datong Railway Station respectively. Zhan Passage and Baoliu Passage are double-track ballastless track passenger dedicated railways with a speed of 350km / h, with strict quality requirements and high technical standards. The Tiejianglu Super Bridge and Shihe Bridge under construction are located in Gongyi City, Henan Province. Both of them were installed due to the high filling height, and bridges were used instead of roads. The 10th to 25th holes and all 8 holes of the Shihe Bridge, a total of 23 holes and a 32m cast-in-place simply supported box girder, were constructed using the pier method. The pier height of the 23-hole box girder is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com