Water tank type wire drawing machine capable of being remotely monitored in real time and monitoring method of water tank type wire drawing machine

A technology of real-time monitoring and wire drawing machine, applied in metal wire drawing, progressive dryer, dryer and other directions, can solve the problems of easy rusting, inconvenient observation, and the wire is not wiped dry in time, etc. Convenience, easy later storage, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

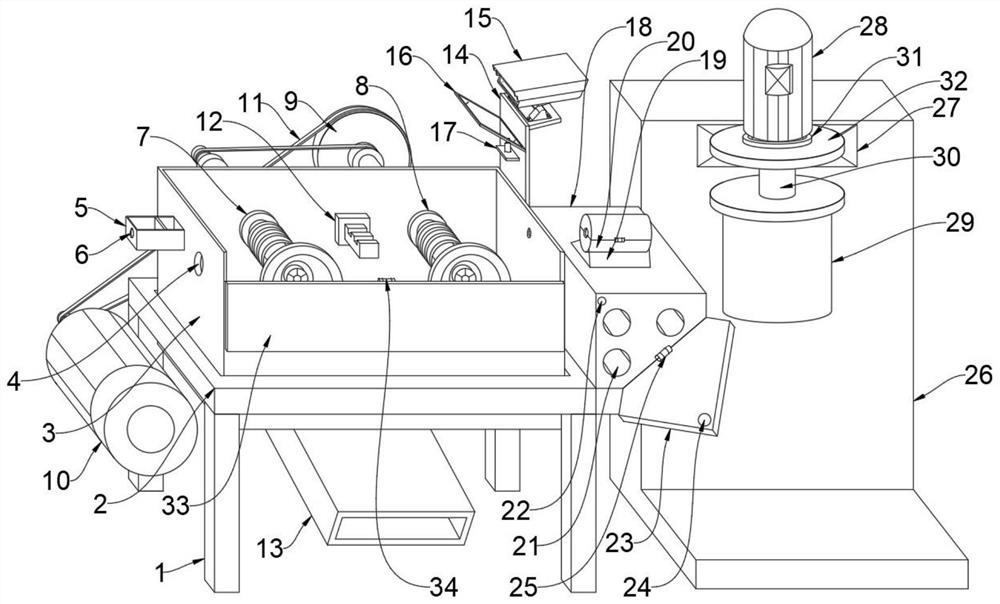

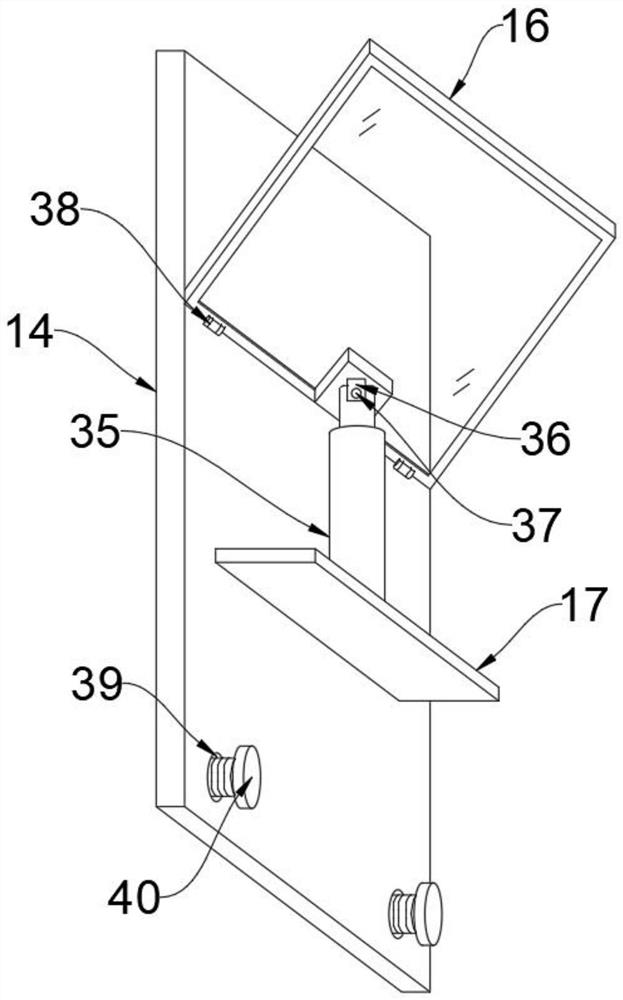

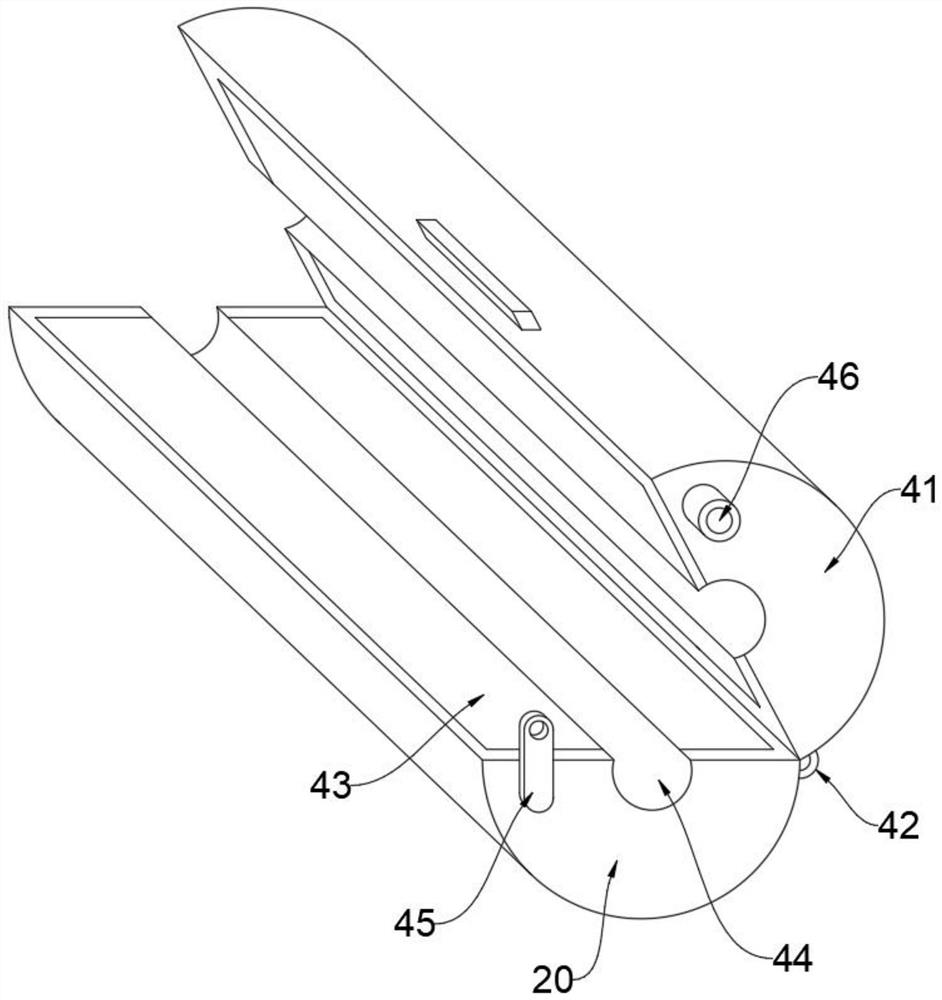

[0031] see Figure 1-5 , an embodiment provided by the present invention: a water tank-type wire drawing machine capable of remote real-time monitoring, including a support column 1, a horizontal frame 2 is provided on the upper end of the support column 1, and a water tank 3 is provided on one side of the horizontal frame 2, The top of water tank 3 is provided with camera mechanism 15, and one side of water tank 3 is provided with dry seat 18, and the top of dry seat 18 is provided with lower round box 20, and the upper end of lower round box 20 is provided with upper round box 41, wipes dry. The front surface of seat 18 is provided with spare groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com