Probe for measuring composition of combustion-supporting gas

A combustion-supporting gas and gas technology, which is applied to the structural details of gas analyzers, measuring devices, and analyzing gas mixtures, etc., can solve the problems of non-real-time measurement and delay, and achieve the best response time and less stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

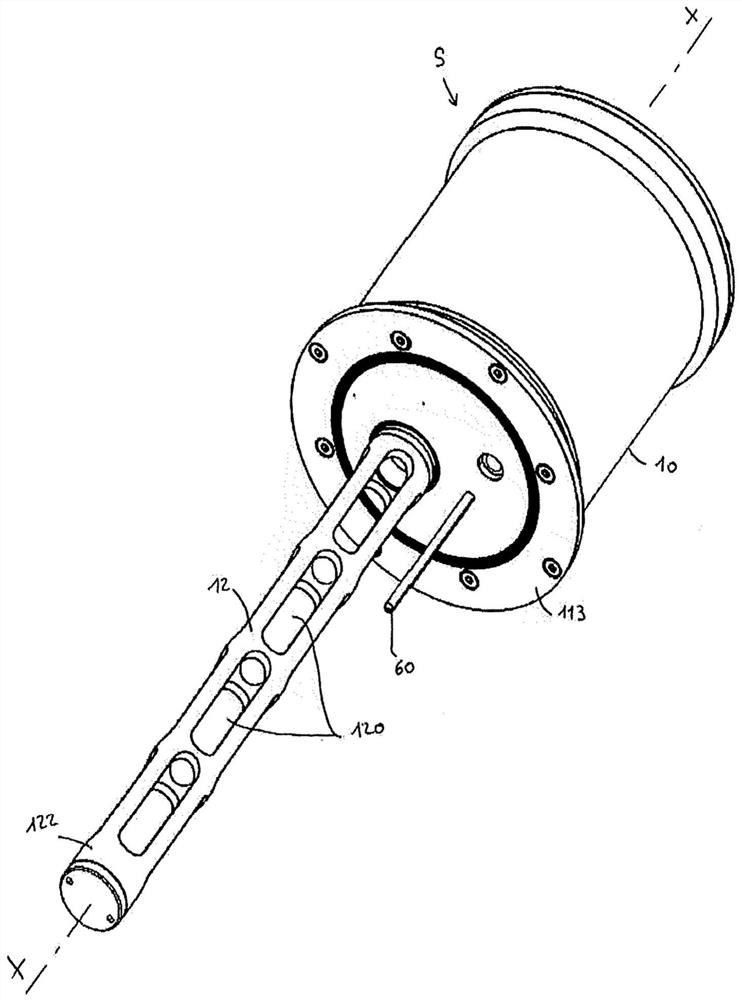

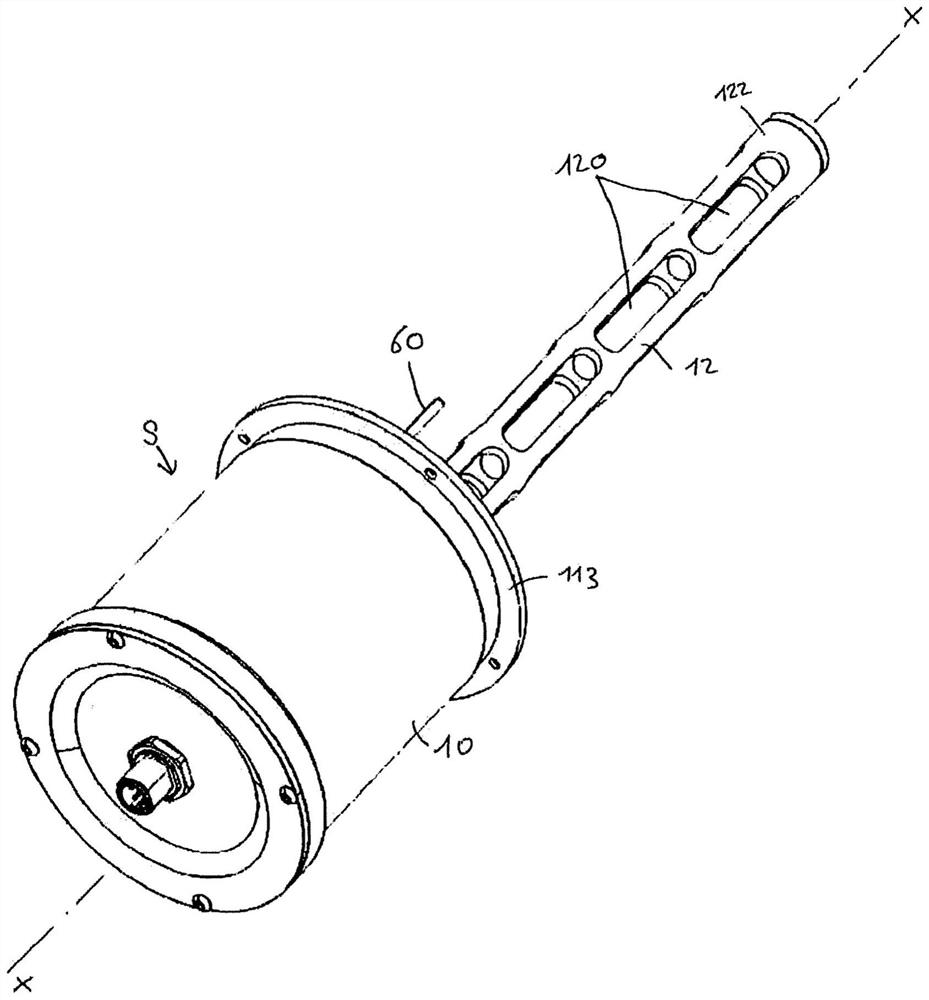

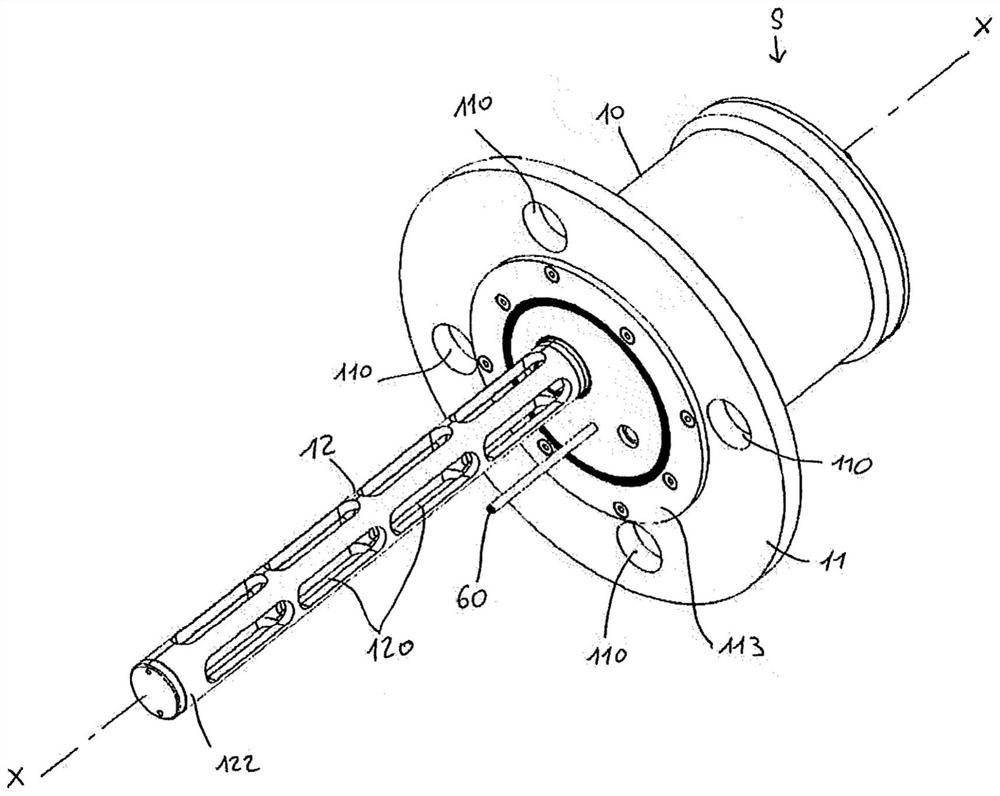

[0072] The target probe of the present invention is used to measure the composition of combustion-supporting gas. The latter is more specifically the gas used as a combustion aid in gas appliances such as gas heat engines, gas burners, gas boilers, gas turbines, and gas furnaces. The gas can also be circulated in lines belonging to a gas pipeline-like distribution network.

[0073] The probe is especially used for the control of gas appliances regardless of the gas quality changes. The probe can better control the appliance by acting on one or several of the following parameters when the gas quality changes: gas and / or air injection velocity, air-gas ratio, ignition advance, etc.

[0074] The gas to be analyzed can be, for example, methane (CH 4 ), ethane (C 2 h 6 ), propane (C 3 h 8 ), isobutane (i-C 4 h 10 ), n-butane (n-C 4 h 10 ), hydrogen (H 2 ), carbon monoxide (CO), carbon dioxide (CO 2 ) or gaseous mixtures of these compounds.

[0075] Gas composition meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com