A process and reactor for converting carbon dioxide into carbon monoxide

A carbon dioxide, carbon monoxide technology, applied in the direction of carbon monoxide, chemical instruments and methods, catalytic treatment of combustible gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

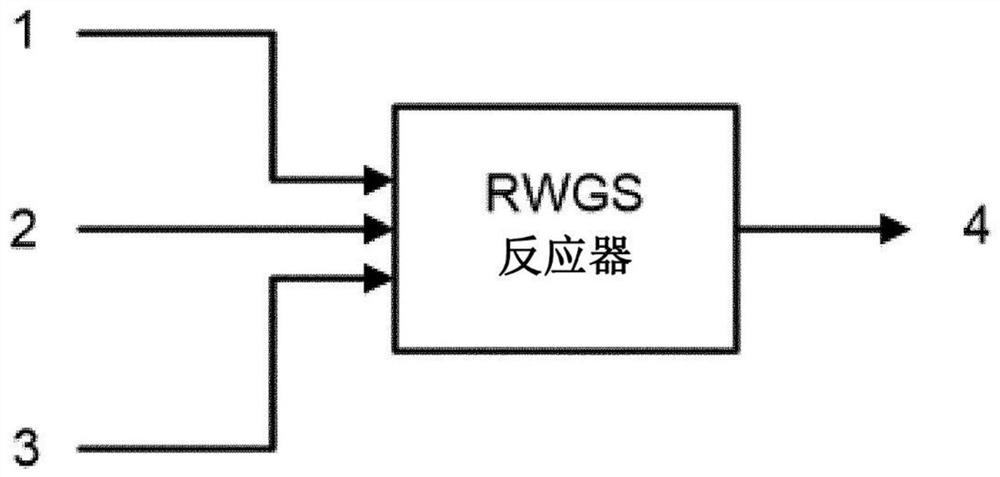

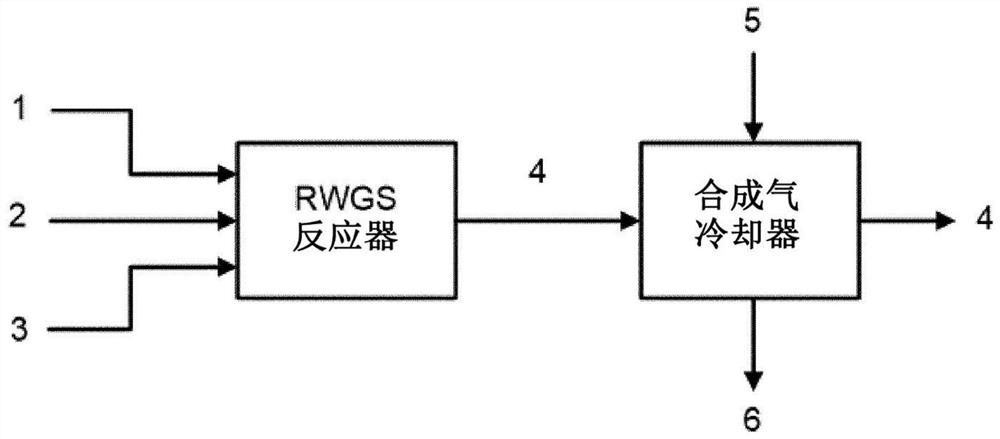

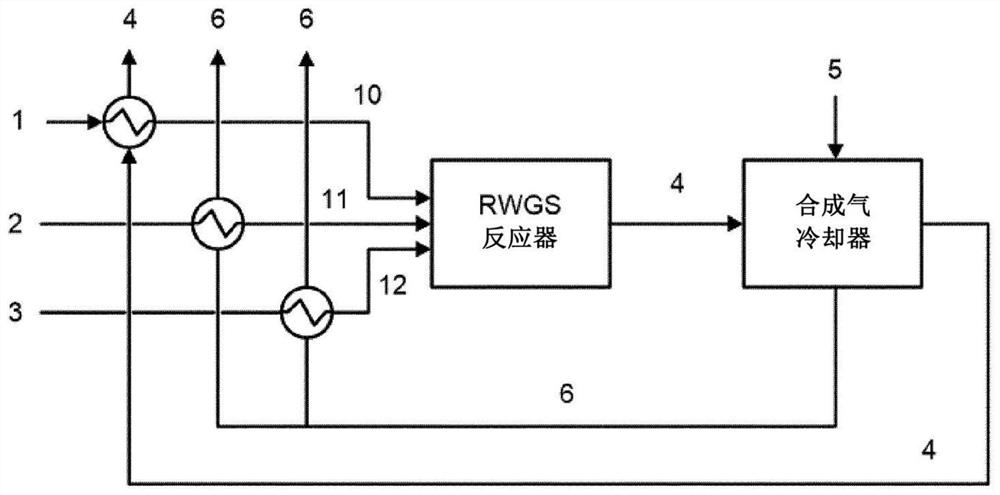

[0010] The present disclosure relates to a RWGS process for converting a gas stream comprising carbon dioxide into products. According to the present disclosure, the feed stream to the reverse water gas shift reactor vessel includes several gas streams: a gas stream comprising at least carbon dioxide, a hydrogen-enriched gas stream, and an oxygen-enriched gas stream. Optionally, additional gas streams may be introduced into the reaction vessel as co-feeds or premixed gas streams (ie, premixed with any other gas streams), such as, but not limited to, streams comprising off-gas or natural gas.

[0011] A gas stream comprising carbon dioxide herein means a gas stream comprising 1% to 100% by volume of carbon dioxide. The source of the carbon dioxide can be various, such as, for example but not limited to, carbon dioxide captured from the air or from flue gas, exhaust, etc. The gas stream comprising carbon dioxide comprises carbon dioxide, and may also comprise other gases, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com