High-voltage isolating switch

A technology of high-voltage isolating switch and one-phase mother, which is applied in the direction of electric switch, high-voltage air circuit breaker, air switch parts, etc., can solve the problems of poor coordination, many moving joints, and large space occupation, and achieve the reduction of assembly accuracy and coordination Degree requirements, simple matching method, and the effect of occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

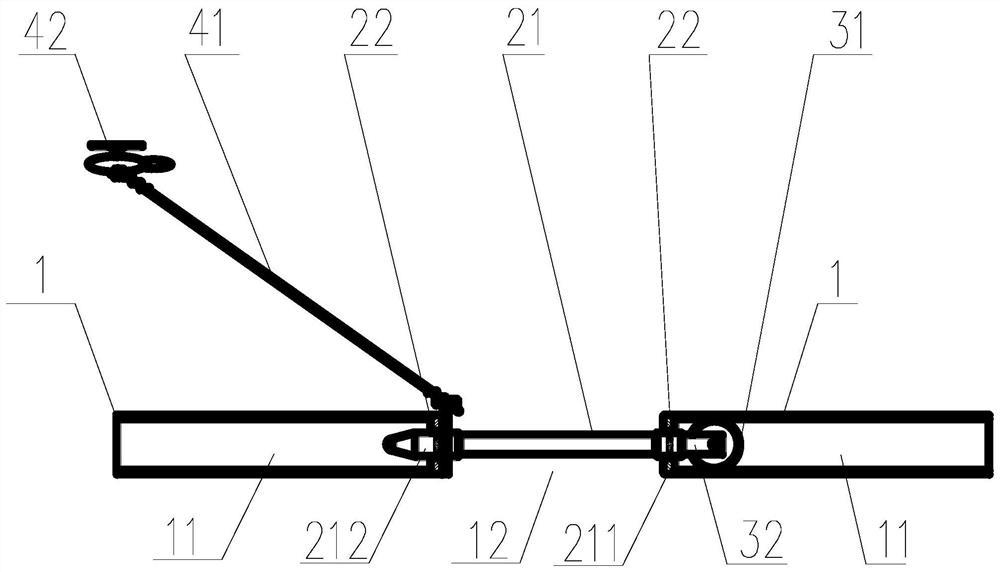

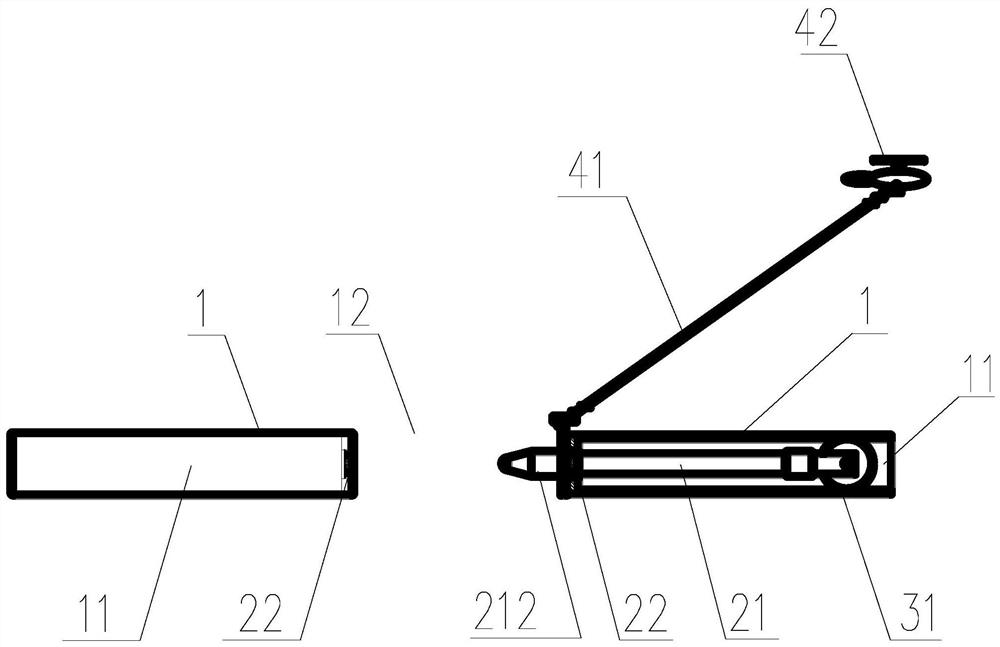

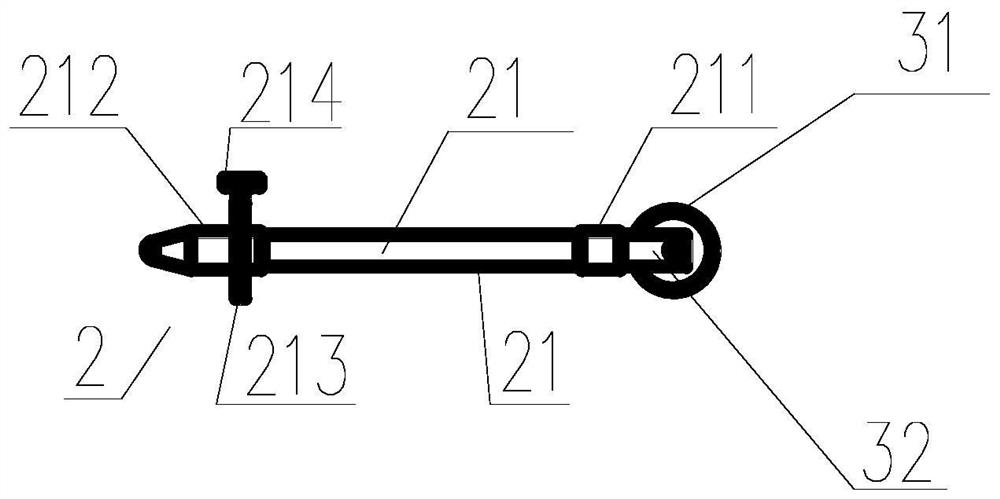

[0020] The following is attached Figures 1 to 3 The given examples further illustrate the specific implementation of a high-voltage isolating switch of the present invention. A high voltage isolating switch of the present invention is not limited to the description of the following embodiments.

[0021] A high-voltage isolating switch, connected between the isolation intervals 12 of at least one phase bus 1, including a contact assembly 2, a moving assembly and a traction assembly, the contact assembly 2 is connected to the traction assembly, and the contact assembly 2 passes through the moving assembly Slidingly matched with the busbar 1, the traction assembly includes a drone 42, which can drive the contact assembly 2 to reciprocate between the isolation intervals 12 along the axis of the busbar 1, so that the isolation intervals 12 are connected or disconnect.

[0022] Compared with the existing high-voltage isolating switch, a high-voltage isolating switch of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com