Cooling system of pivoting equipment

A cooling system and equipment technology, applied in the direction of mechanical equipment, gear lubrication/cooling, material thermal expansion coefficient, etc., can solve the problems of indirect and inaccurate, not sensitive enough, not direct enough in temperature measurement, etc., to achieve optimal detection and cooling, The detection method is accurate and the effect of protecting the rotating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

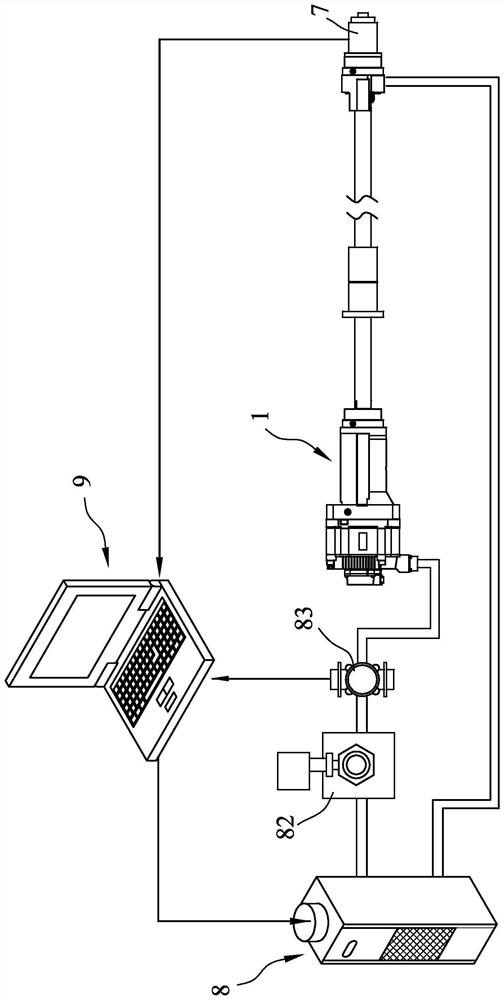

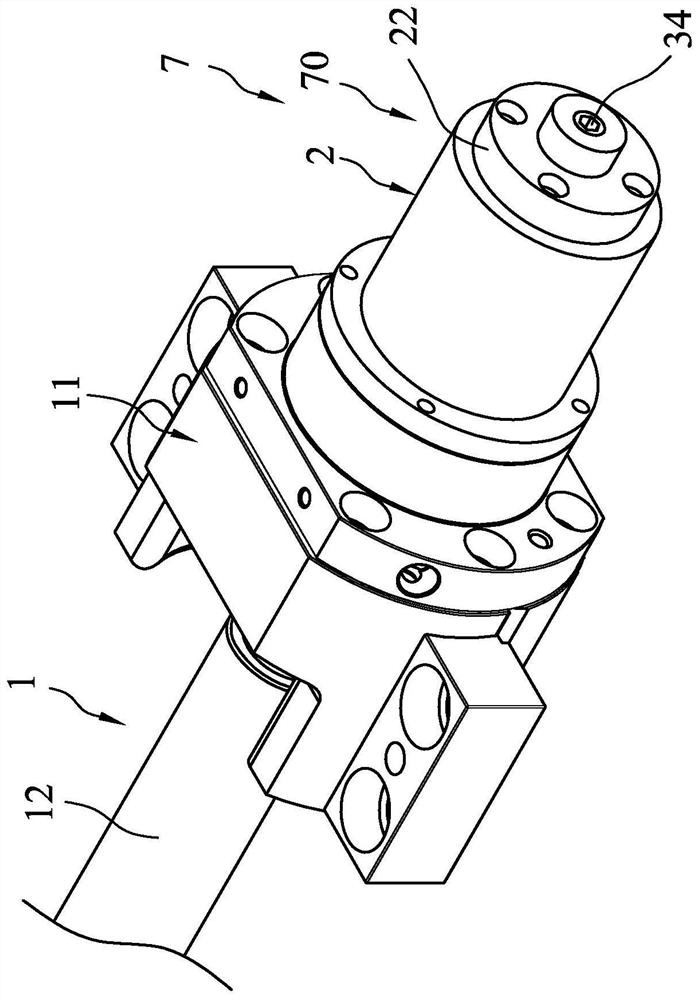

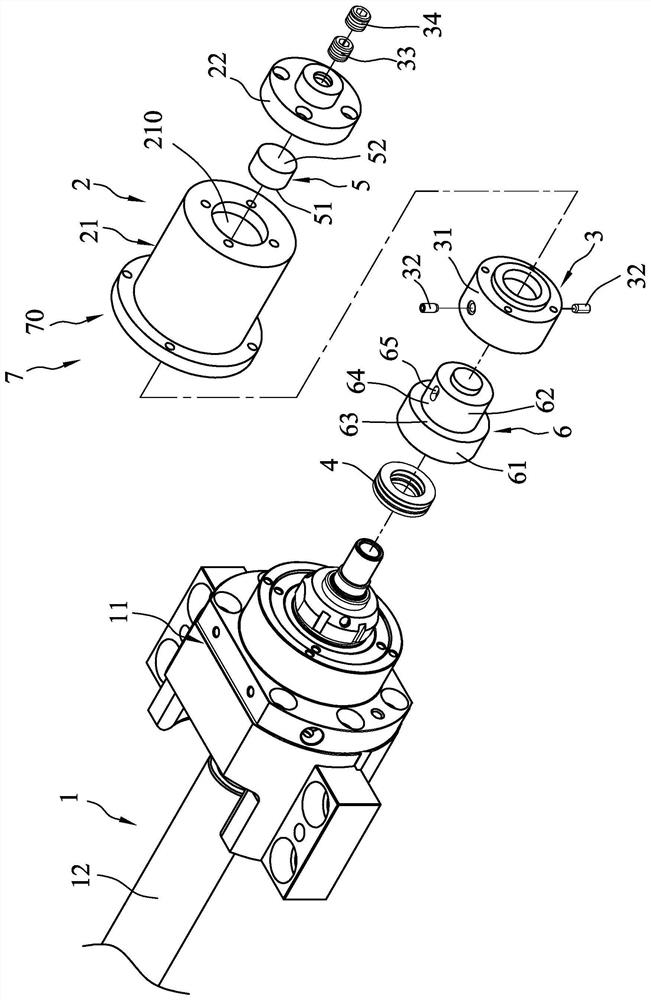

[0038] refer to Figure 1~4 , the first embodiment of the cooling system of the rotary device 1 of the present invention is suitable for providing a cooling fluid to cool the rotary device 1, the rotary device 1 includes a hollow base 11, a rotatably penetrating through the The rod body 12 of the base 11 and a bearing unit 13 installed in the base 11 and through which the rod body 12 can rotatably pass through. The cooling system of the first embodiment includes a thermal elongation measuring device 7 , a cooling machine 8 , a control valve 82 , a flow meter 83 , and a control unit 9 .

[0039] The thermal elongation measuring device 7 is combined with the pivoting device 1 and used to measure the elongation of the pivoting device 1 after being heated during the rotation process. Specifically, the thermal elo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com