Low-hardness high-tear-resistance natural latex material suitable for space environment and preparation method thereof

A natural latex and space environment technology, applied in the field of latex materials, can solve the problems of low hardness, high strength, high and low temperature resistant natural latex rubber material formula components, etc., to achieve excellent heat resistance, wide applicability, and good comprehensive performance of the film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

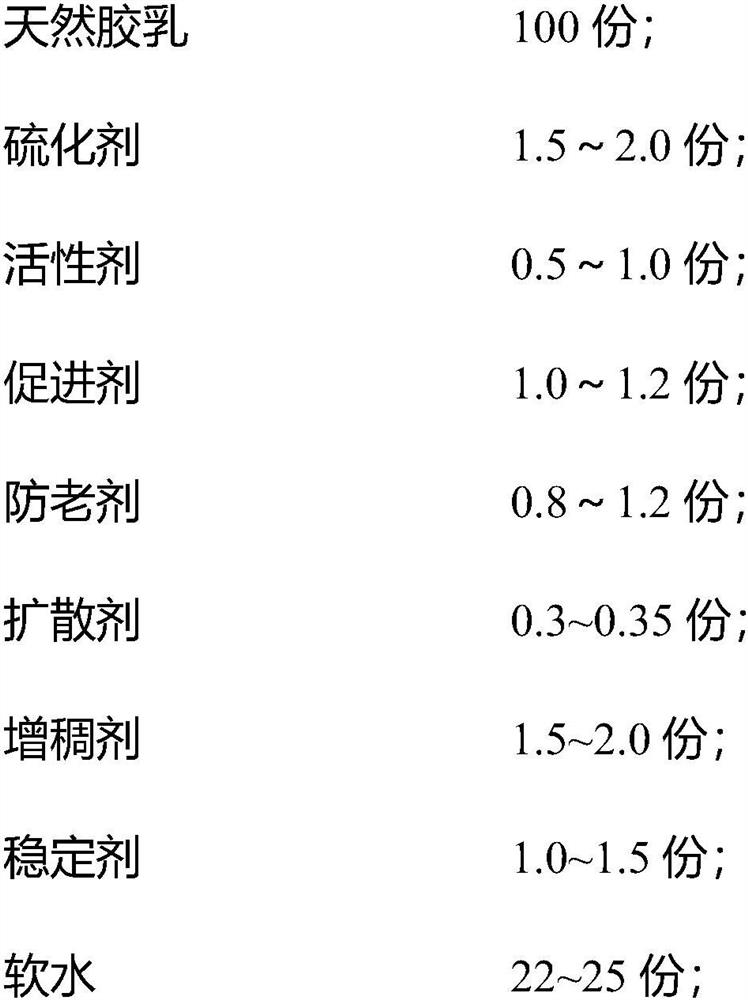

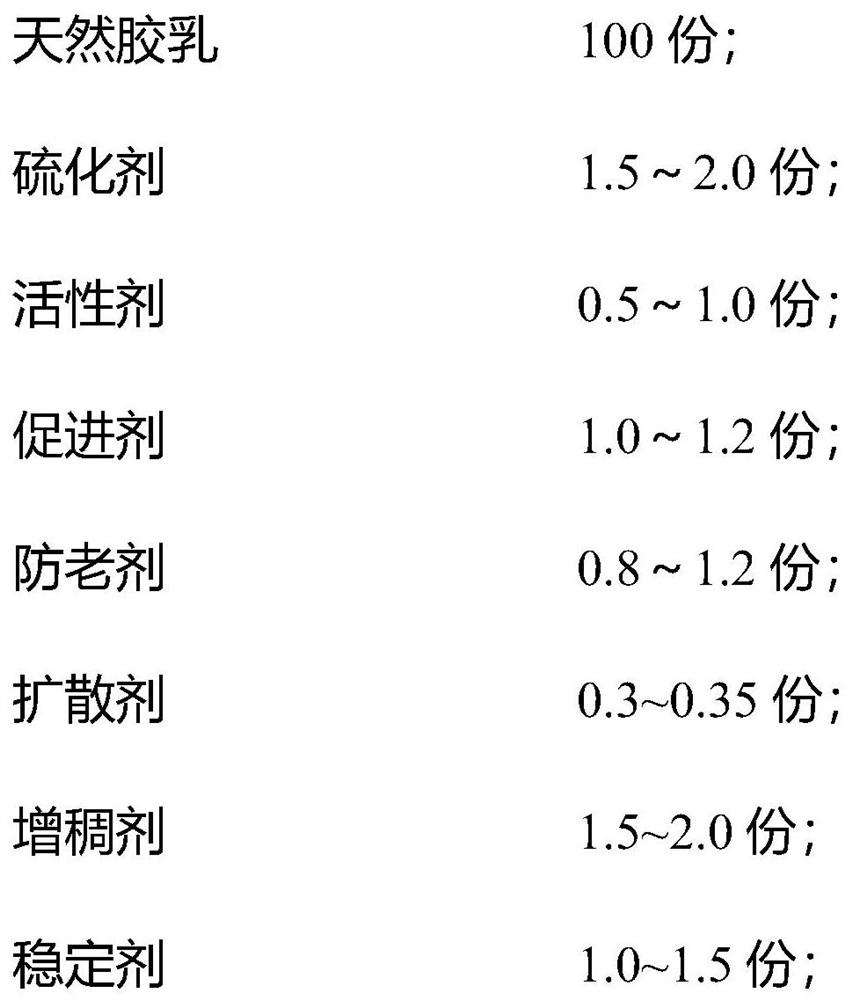

[0043] A kind of preparation method of the low hardness high tear resistance natural latex material that is applicable to space environment, comprises the following steps:

[0044] (1) Add soft water, stabilizing agent, diffusing agent, thickener successively in natural rubber latex, mix; Preferably, weigh natural latex in the rubber mixing bucket, add 1 / 2 of soft water, stabilizing agent, Diffusion agent, thickener, stirring for 3 to 5 minutes;

[0045] (2) Add vulcanizing agent, accelerant, anti-aging agent, active agent to the product obtained in step (1) in sequence, and stir for 3 to 5 minutes to mix;

[0046] (3) Add soft water, mix and let stand, preferably, add the remaining 1 / 2 soft water, stir for 3-5min; stand for 4-6h;

[0047](4) Filter the product obtained in step (3), homogenize it, and leave it to stand before processing and molding; preferably, the latex after standing is filtered into the homogenizer with double-layer gauze, and the chloroform value of the t...

Embodiment 1

[0051] A method for preparing a low-hardness and high-tear-resistant natural rubber latex material suitable for space environments:

[0052] (1) Compounding: Weigh the natural rubber latex in the rubber mixing bucket, add one-half of the soft water, stabilizer, diffusing agent, and casein in sequence, and stir for 3 to 5 minutes;

[0053] (2) Then add vulcanizing agent, accelerator, anti-aging agent and active agent in turn, and stir for 3-5 minutes;

[0054] (3) Finally, add the remaining 1 / 2 soft water, stir for 3-5 minutes; let stand for 4-6 hours.

[0055] (4) filter: the latex after standing is filtered in the homogenizer with double-layer gauze, after homogenizing, the gained glue stands for subsequent use after standing 24h. The chloroform value of the mucilage after homogenizing is the first to the second end;

[0056] The ceramic or aluminum mold impregnated with coagulant can be processed into the required elastic product by immersing in the mortar. The immersion c...

Embodiment 2

[0065] A method for preparing a low-hardness and high-tear-resistant natural rubber latex material suitable for space environments:

[0066] (1) Compounding: Weigh the natural rubber latex in the rubber mixing bucket, add one-half of the soft water, stabilizer, diffusing agent, and casein in sequence, and stir for 3 to 5 minutes;

[0067] (2) Then add vulcanizing agent, accelerator, anti-aging agent and active agent in turn, and stir for 3-5 minutes;

[0068] (3) Finally, add the remaining 1 / 2 soft water, stir for 3-5 minutes; let stand for 4-6 hours.

[0069] (4) filter: the latex after standing is filtered in the homogenizer with double-layer gauze, after homogenizing, the gained glue stands for subsequent use after standing 24h. The chloroform value of the mucilage after homogenizing is the first to the second end;

[0070] The ceramic or aluminum mold impregnated with coagulant can be processed into the required elastic product by immersing in the mortar. The immersion c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com