Triple-repair double-crosslinked polysiloxane super-hydrophobic elastomer and preparation method thereof

A technology of polysiloxane and elastomer, applied in the direction of coating, etc., to achieve the effect of easy operation, good product performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Triple-repaired double-crosslinked polysiloxane superhydrophobic elastomer, the compound (i.e. triple-repaired double-crosslinked polysiloxane superhydrophobic elastomer, or a novel silicone elastomer with imine / coordination double-crosslinked structure , or super-hydrophobic self-healing polydimethylsiloxane elastomer, referred to as HB-imine-BZn-PDMS) has the chemical structural formula shown in (I):

[0040]

[0041] In the formula: x:y:z:=90:8:2;

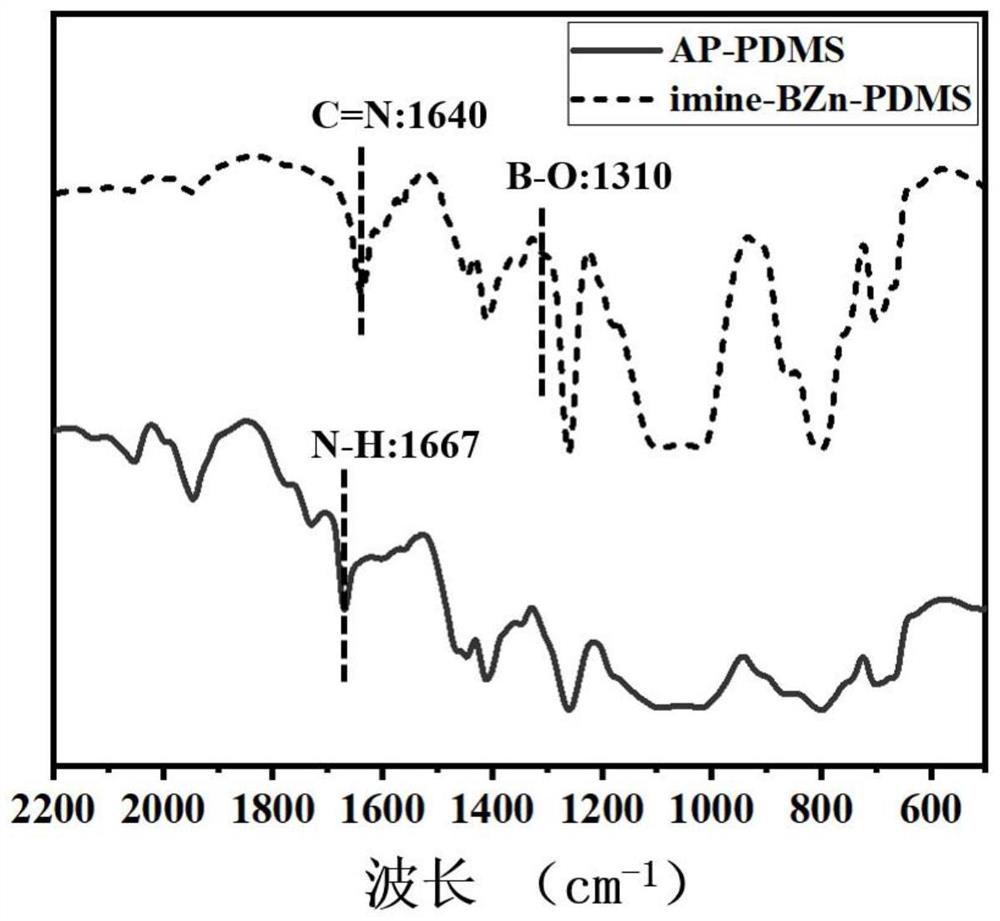

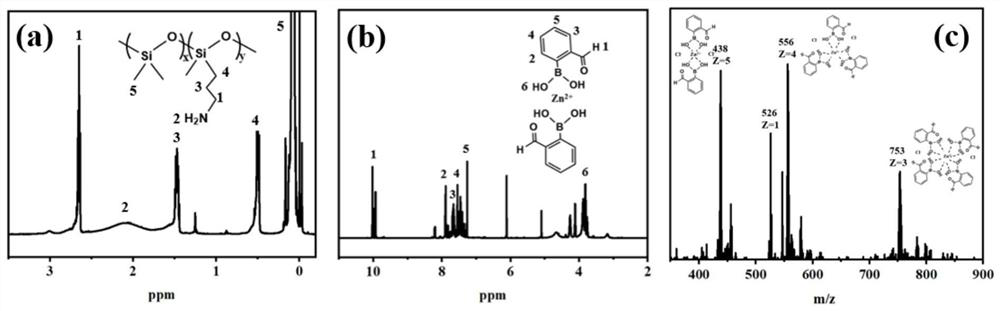

[0042] The basic feature of the compound (I) is: transparent orange-yellow elastomer; the structural characterization is as follows: infrared spectrum IR (KBr tablet, cm -1 ): 1640(C=N), 1310(B-O); 1 H NMR (600MHz, CDCl 3 ) δ (ppm): 10.0 (-CHO), 3.8 (b-O-H); the molecular weight is ~11800 (molecular weight is about 11800), and the molecular weight distribution is 3.75.

Embodiment 2

[0044] The preparation method of the double-crosslinked polysiloxane superhydrophobic elastomer of triple repair, the steps are as follows:

[0045] a. Preparation of (2-formylphenylboronic acid) zinc chloride [abbreviated as CHO-Bz]:

[0046] Add 0.45 to 0.55 g of 2-formylphenylboronic acid into a reactor (such as a 50 mL flask, etc.), add 18 to 22 mL of ethanol, ultrasonically disperse, add 0.22 to 0.24 g of zinc chloride, and stir (at room temperature) for 22 ~26 hours. Ethanol was rotary distilled at a temperature of 40-60° C. to obtain (orange product) (2-formylphenylboronic acid) zinc chloride [abbreviated as CHO-Bz], and set aside;

[0047] b. Preparation of side chain aminated polysiloxane [abbreviated as AP-PDMS]:

[0048] Add 50g of octamethylcyclotetrasiloxane, 14.3g of aminopropylmethyldiethoxysilane, 0.20g of dimethylsulfoxide, 0.1g of Potassium, 1.5mL of deionized water; react under nitrogen atmosphere at 90°C for 4 hours, then lower the temperature to 60°C, a...

Embodiment 3

[0059] The preparation method of the double-crosslinked polysiloxane superhydrophobic elastomer of triple repair, the steps are as follows:

[0060] a. Preparation of (2-formylphenylboronic acid) zinc chloride [abbreviated as CHO-Bz]:

[0061] Add 0.45 g of 2-formylphenylboronic acid to a reactor (such as a 50 mL flask, etc.), add 18 mL of ethanol, ultrasonically disperse, add 0.22 g of zinc chloride, and stir (at room temperature) for 22 hours. Ethanol was rotary distilled at a temperature of 40-60° C. to obtain (orange product) (2-formylphenylboronic acid) zinc chloride [abbreviated as CHO-Bz], and set aside;

[0062] b. Preparation of side chain aminated polysiloxane [abbreviated as AP-PDMS]:

[0063] Add 48g of octamethylcyclotetrasiloxane, 13.8g of aminopropylmethyldiethoxysilane, 0.20g of dimethyl sulfoxide, 0.09g of Potassium, 1.3mL of deionized water; react for 5 hours under a nitrogen atmosphere at a temperature of 85°C, then lower the temperature to 55°C, and remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com