Oily sludge treatment system and method

A technology of sludge treatment and sludge, applied in the field of heating and distillation separation of materials, can solve the problems of low efficiency of treatment methods, large environmental pollution, secondary pollution, etc., and achieve improved energy utilization, low operating costs, and harmless treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

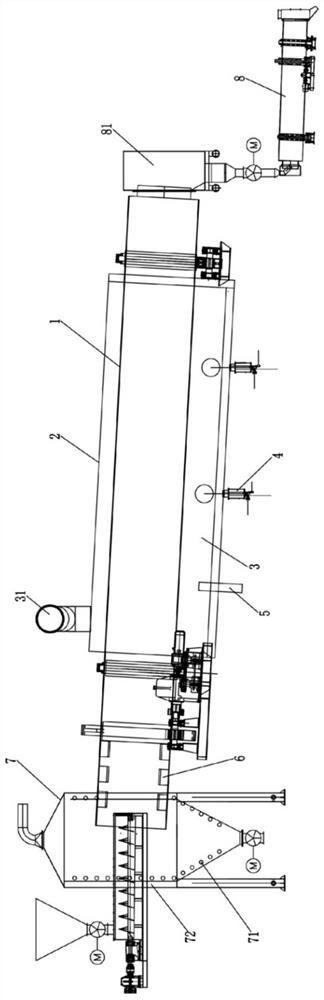

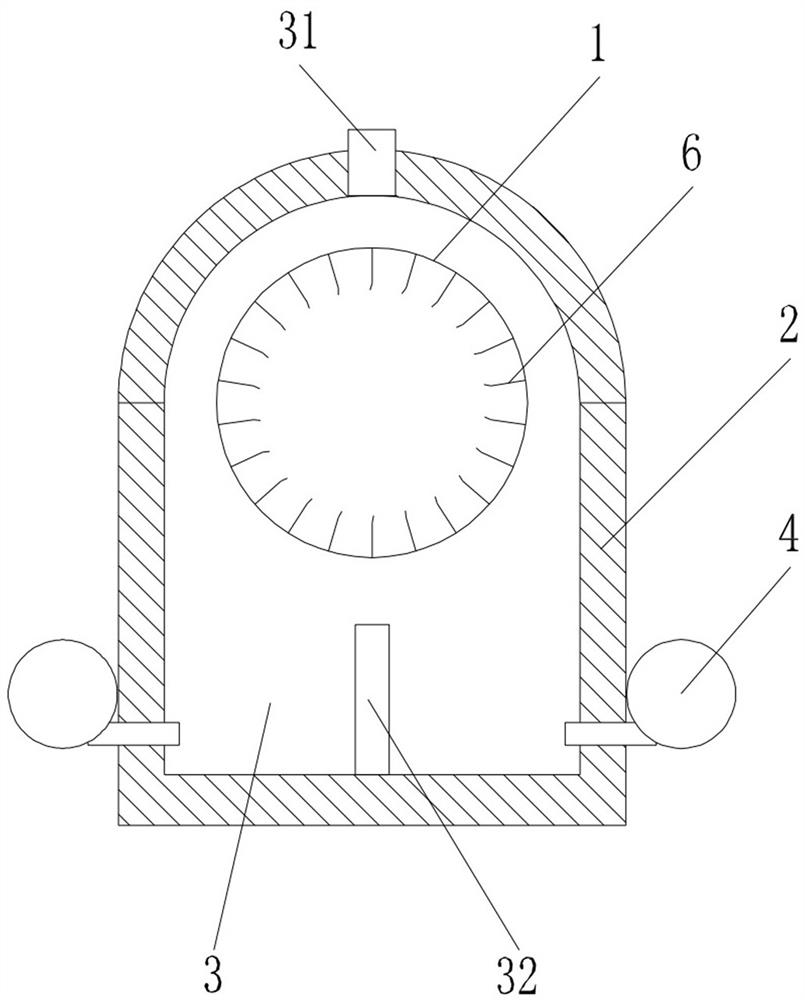

[0055] Such as Figure 1 to Figure 12 As shown, an oily sludge treatment system mainly includes an anaerobic distillation system and a condensation separation system. The anaerobic distillation system includes a rotary drum 1 and a casing 2 surrounding the peripheral periphery of the rotary drum 1. The casing 2 and the rotary drum There is a space between 1 to form a heating chamber 3. The heating chamber 3 surrounds the circumference of the rotary drum 1. A heating system is arranged on the heating chamber 3. The heating system adopts fuel combustion for heating. The rotary drum 1 is a cylinder with openings at both ends, which is driven by a motor assembly to rotate around its axis, and the casing 2 is placed statically, that is, the rotary cylinder 1 rotates relative to the casing 2 inside the casing 2, and the rotary cylinder 1 In the axial direction, sealing mechanisms are respectively provided between the two ends of the casing 2 and the rotating cylinder 1, there is a r...

Embodiment 2

[0084]The difference from Embodiment 1 is that both the condenser and the slag cooling device of the condensation separation system use water as the cooling medium, and the water absorbs the heat of the distillation gas at the condenser and the temperature rises. At the same time, the water in the slag The cooling device absorbs the heat of the sludge and the temperature rises. The heated water is usually sent to the cooling tower to cool down and then circulated to the condenser and the slag cooling device for use. This method wastes heat. Here, the gas-liquid The heat exchange device is to pass the heated water into the gas-liquid heat exchange device to preheat the combustion-supporting gas and non-condensable gas to improve the sufficient rate of heat utilization. The device is preheated by the heated water, and then the combustion gas and non-condensable gas are preheated by the flue gas through the heat exchanger, making full use of heat, improving energy utilization effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com