A large-area, thickness-controllable two-dimensional material nanosheet and its general preparation method

A two-dimensional material and large-area technology, applied in the field of two-dimensional material film and its general preparation, can solve the problems of difficult control of the thickness of two-dimensional layered material film material, restriction of practical application, and poor applicability, so as to avoid high temperature The unevenness of oxidation and thickness, the experimental operation is simple and easy, and the heating effect is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

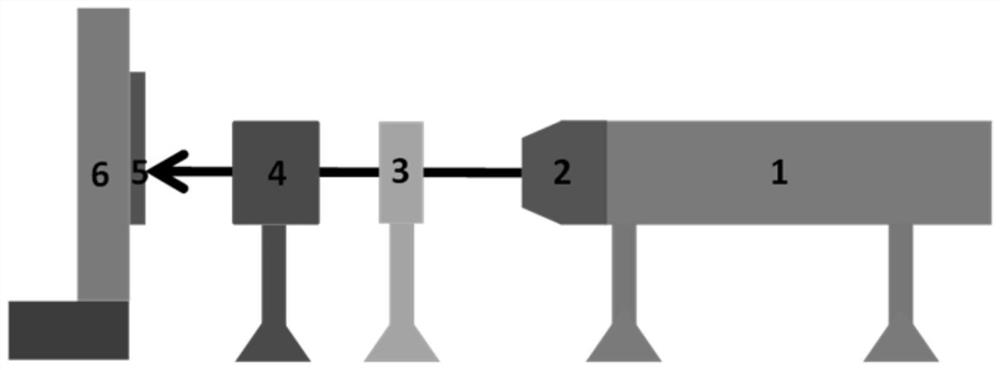

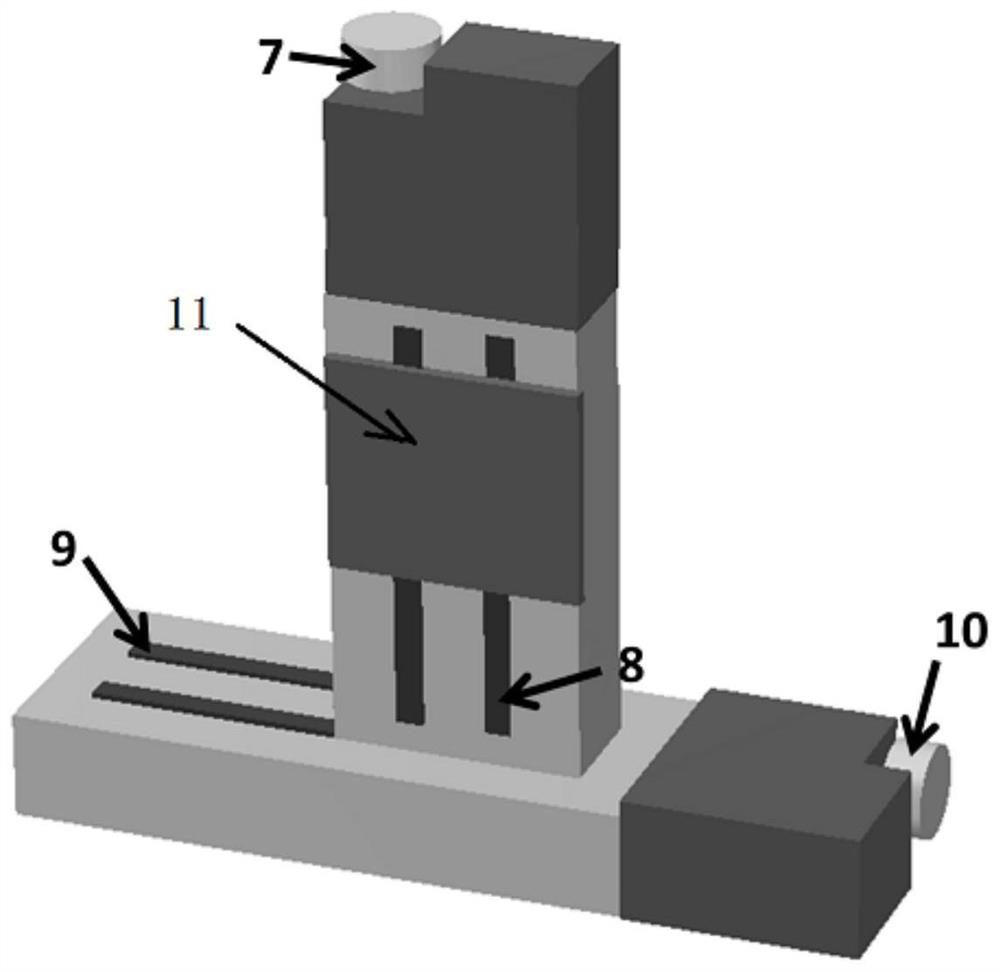

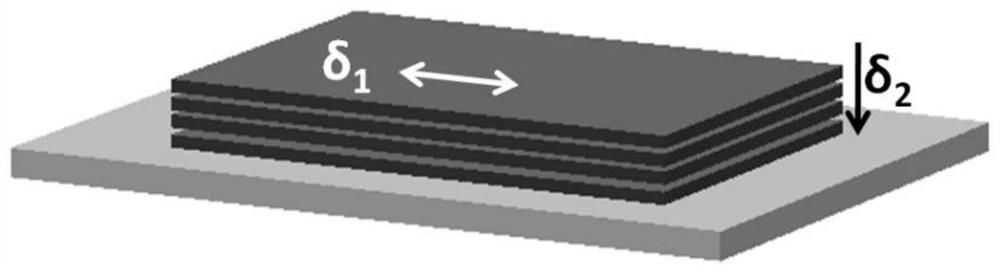

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a graphene film with a size of 10 cm and a thickness of 1 to 100 layers with controllable thickness, the preferred embodiment is explained in detail below:

[0043] 1) The preparation of 100 layers of graphene film comprises the following steps:

[0044] A large area of 100-layer graphene is grown using a CVD material growth process. The selected substrate material is nickel foil with a thickness of 300 nanometers. The nickel foil is etched in dilute nitric acid for 15 minutes, rinsed, and dried with nitrogen; the nickel foil is immediately put into the CVD chamber, and the chamber is evacuated to 500mTorr.

[0045] The growth temperature is 1000°C, the raw material is a mixture of methane and hydrogen, and the gas flow rates are 35sccm and 2sccm respectively, and a large area (10cm*10cm) of clean 100-layer graphene is grown.

[0046] Prepare 4 inches of SiO 2 substrate; the SiO 2 The substrate was ultrasonically cleaned with acetone, isoprop...

Embodiment 2

[0054] A method for preparing a molybdenum disulfide thin film with a size of 10 cm and a thickness from a single layer to 50 layers with a controllable thickness, the preferred embodiment is explained in detail below:

[0055] 1) The preparation of 50 layers of molybdenum disulfide film comprises the following steps:

[0056] A large-area molybdenum disulfide film with a thickness of 50 layers was grown by PVD material growth process. The selected substrate material is SiO 2 , the SiO 2 Place in acetone, isopropanol, ethanol, and deionized water for ultrasonication, rinse, and blow dry with nitrogen; 2 Immediately place in a PVD chamber and evacuate the chamber to 500 mTorr.

[0057] The growth temperature is 800°C, the raw material is high-purity molybdenum disulfide powder, argon is used as the carrier, and the gas flow rate is 100 sccm. A large-area (10 cm*10 cm) surface-clean 50-layer thick stone molybdenum disulfide film is grown.

[0058]PMMA is spin-coated onto the...

Embodiment 3

[0066] A method for preparing a thickness-controllable black phosphorus film with a size of 10 cm and a thickness of 10 to 100 layers. The preferred implementation is explained in detail below:

[0067] 1) The preliminary preparation of the reactant comprises the following steps:

[0068] Prepare 4 inches of SiO 2 substrate; the SiO 2 The substrate was ultrasonically cleaned with acetone, isopropanol, and deionized water for 15 minutes in sequence, and dried for later use; a 1 mg sample of monocrystalline black phosphorus was placed on an adhesive tape, and mechanical peeling was repeated 10 times without overlapping; the black phosphorus obtained by mechanical peeling Nanosheet transfer to cleaned SiO 2 On the substrate; the PMMA is spin-coated onto the surface of the black phosphorus material by a spin-coating machine, and the spin-coating condition is: under 800 revolutions per minute, the time is 10 seconds; under 4000 revolutions per minute, the time is 40s; for spin co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com