External cable follow-up device of electric transformation equipment for tunnel excavation

A technology for excavating tunnels and connecting external cables is applied in the field of external cable follow-up devices for excavating tunnels using electricity to change equipment, and can solve problems affecting tunnel operation efficiency, quality operation safety, increase in toxic and harmful substances, and equipment power decline. , to ensure the safety of power supply, avoid cable entanglement, and reduce power components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

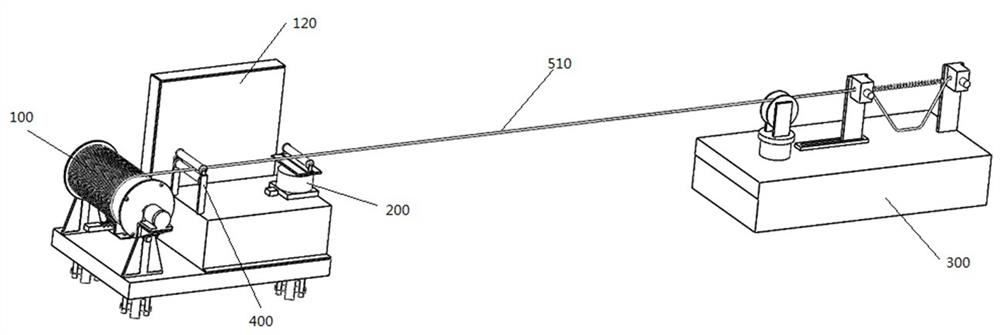

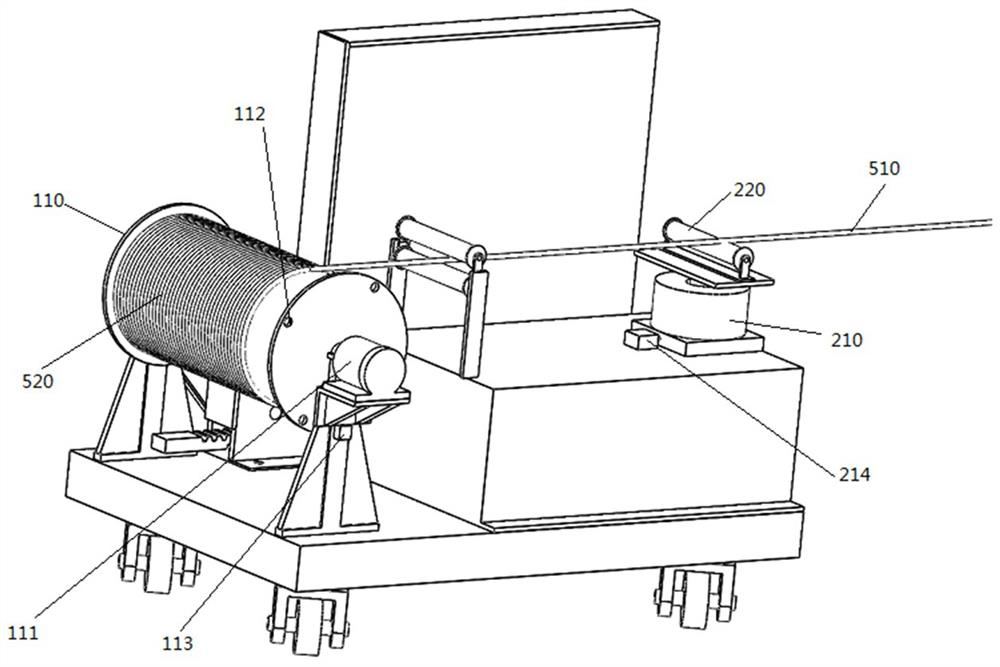

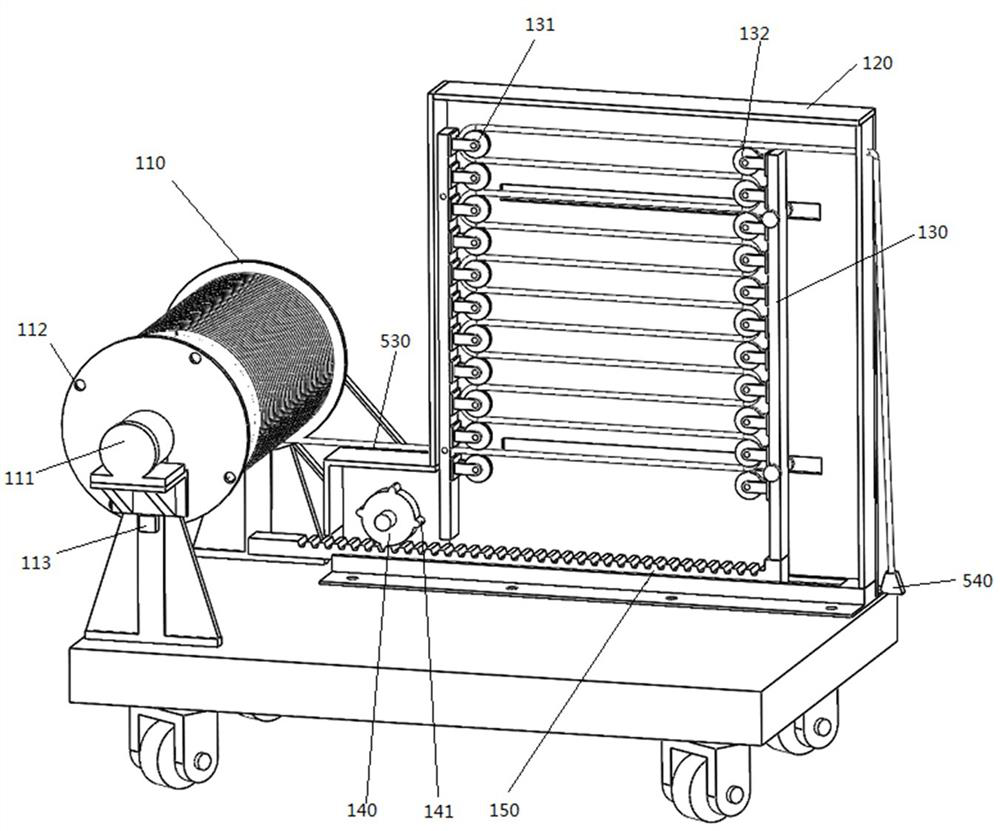

[0038] Such as Figure 1 to Figure 7As shown, an external cable follower for excavating tunnel power conversion equipment includes a winding and unwinding device 100, a weighing device 200 and cables. The winding and unwinding device 100 includes a reel 110 , a motor 111 and a counter 113 . The motor 111 is used to drive the reel 110 to rotate. A counting hole 112 is provided at one end of the reel 110 deviated from the center of the circle, and a counter 113 is matched with the counting hole 112 , and the counter 113 is used for counting when the counting hole 112 passes the position of the counter 113 . The force measuring device 200 includes a weighing device 210 and a carrying roller 220 , and the carrying roller 220 is rotatably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com