Hydraulic rolling wheel device, telescopic supporting leg with hydraulic rolling wheel device and engineering machinery

A technology of telescopic outriggers and rollers, which is applied in the direction of casters, wheels, transportation and packaging, etc. It can solve the problems of unsmooth telescopic outriggers and large frictional resistance, and achieve the effect of improving the smoothness of telescopic and reducing the telescopic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

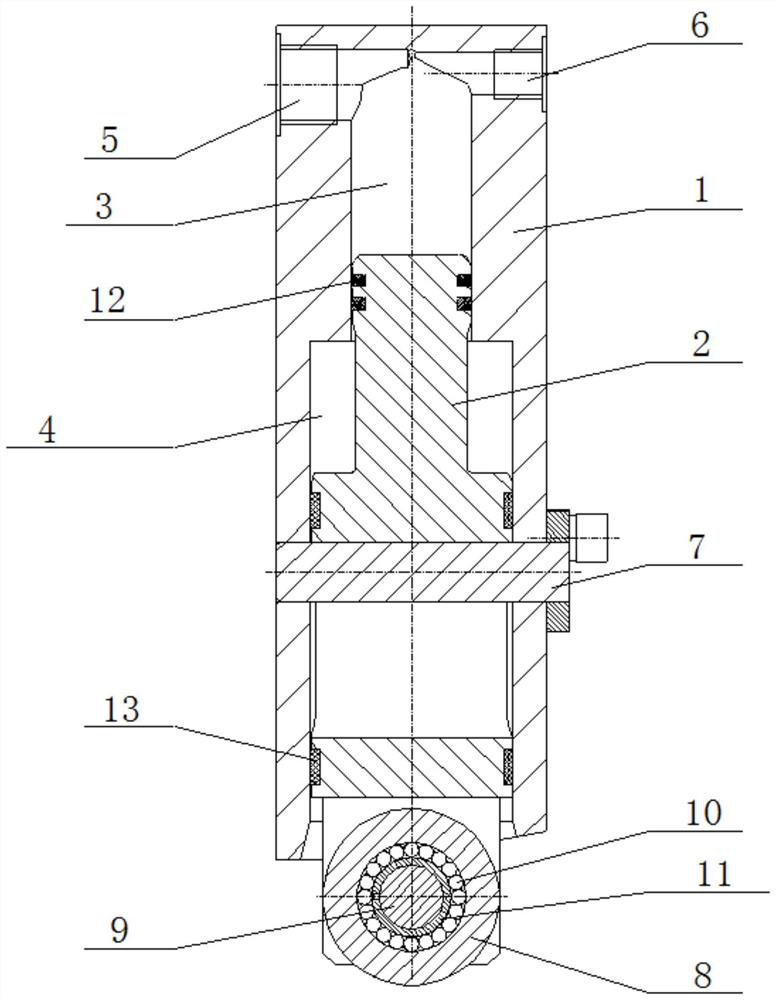

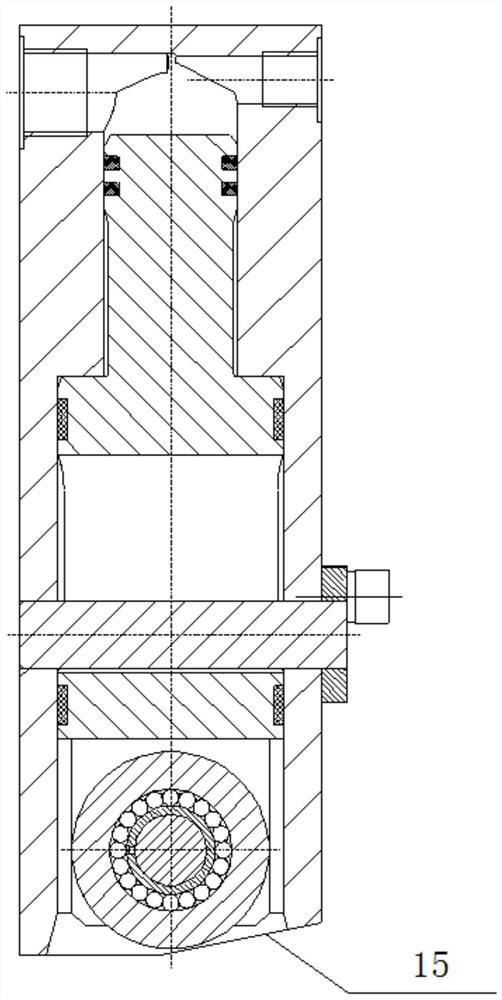

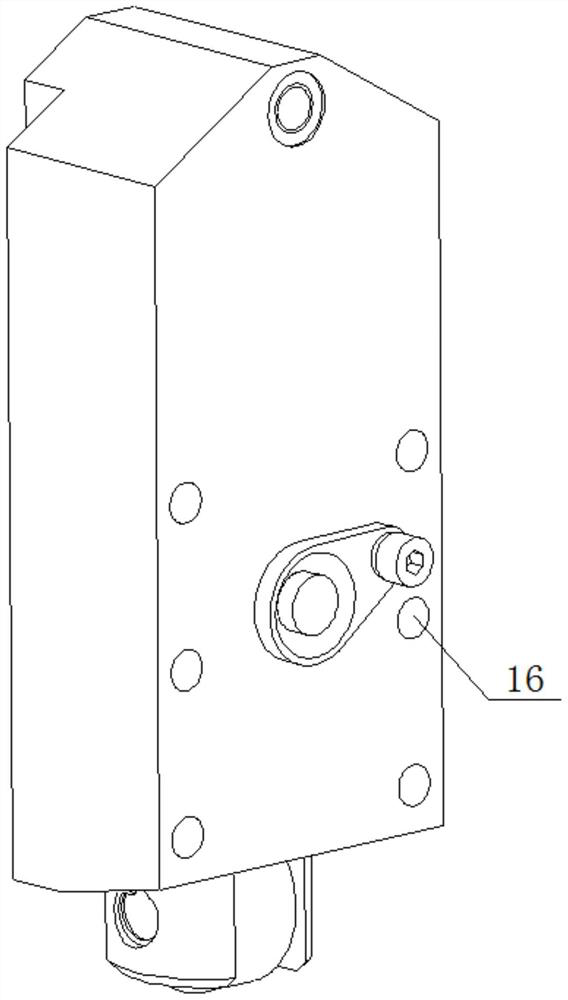

[0030] like Figure 1-7 As shown, a hydraulic roller device includes a valve body 1, a piston rod 2, a rolling structure and a limiting device.

[0031] The valve body 1 is provided with a high-pressure oil chamber 3 , a supporting and guiding chamber 4 , an oil inlet 5 , and a pressure measuring port 6 . The high-pressure oil chamber 3 communicates with the supporting and guiding chamber 4 and is a stepped hole; the oil inlet 5 and the pressure measuring port 6 are both connected with the high-pressure oil chamber 3 . The rolling structure includes a roller 8 and a roller shaft 9; a rolling body 10 and a supporting inner ring 11 are arranged between the roller 8 and the roller shaft 9;

[0032] The valve body 1 is provided with a limiting device, the limiting device includes a limiting pin and a limiting pin hole, the limiting pin is installed in the limiting pin hole on the valve body, and passes through the hole on the piston rod. An oblong hole; the limit pin performs te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com