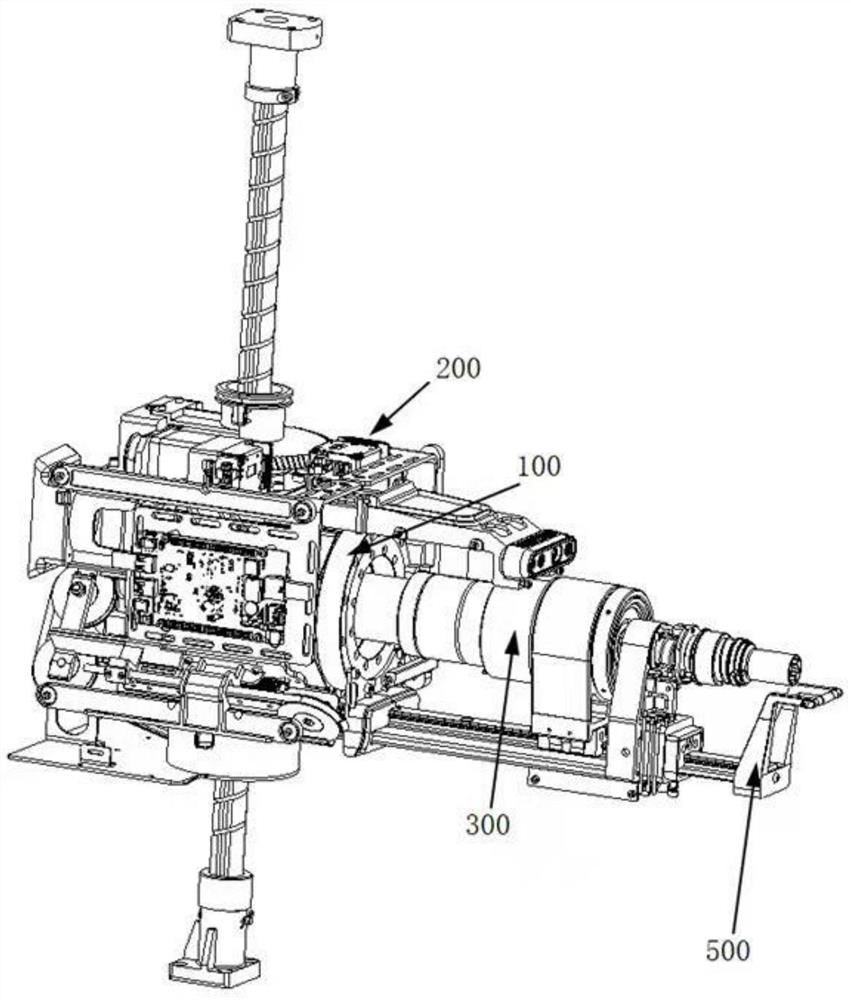

Switch cabinet grounding knife switch operating mechanism

A grounding knife switch and operating mechanism technology, applied in the field of indoor operation robots, can solve the problems of exposed endoscope wire harness, poor overall structure rigidity, easy wear and tear, etc., to improve the operation success rate, reduce the expansion resistance, and increase the rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

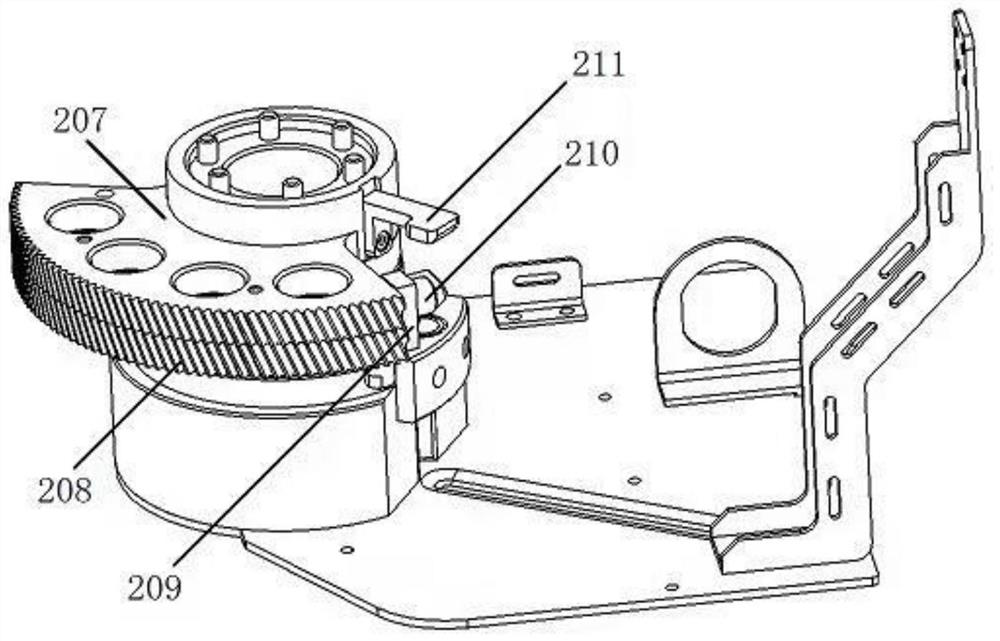

Method used

Image

Examples

specific Embodiment approach

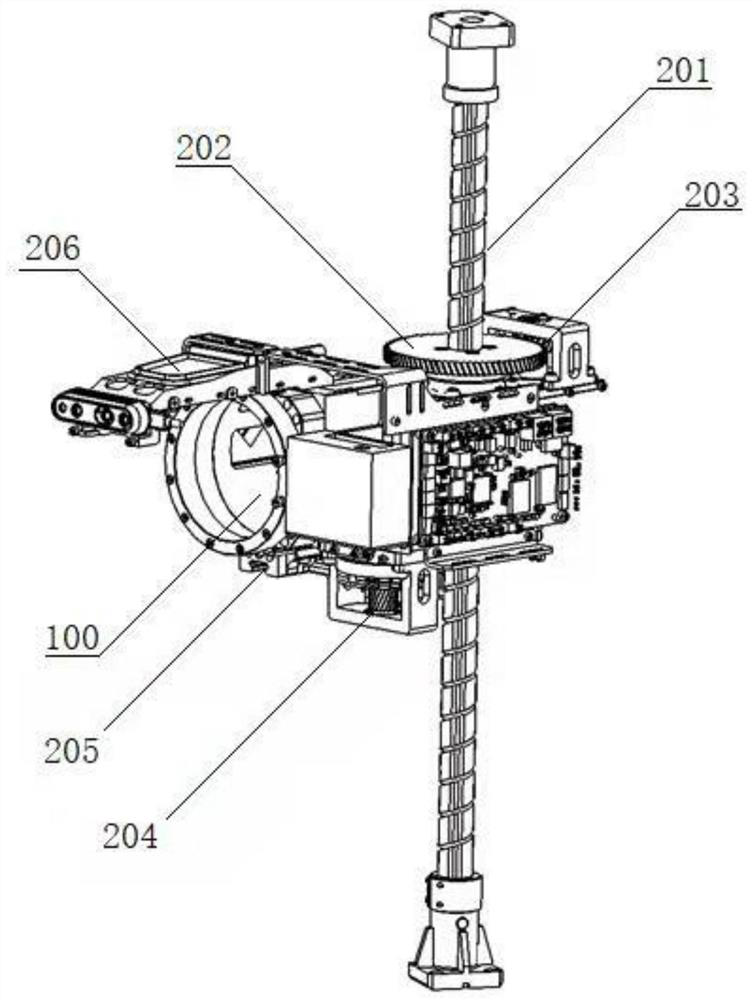

[0059] S1 Coarse positioning: After the robot is in place, the posture adjustment of the rack 100 is realized through the cooperation of the rack assembly 200 and the depth camera 206 until the operation assembly 300 rotates to a position perpendicular to the switch cabinet surface, and the pressure plate assembly 500 is located on the ground. above the knife cover;

[0060] S2 Open the floor knife cover: the output shaft assembly drives the pressure plate assembly 500 to extend until the floor knife pressure plate 501 is against the cabinet surface, and then the frame assembly 200 drives the pressure plate assembly 500 to press down the floor knife cover;

[0061] S3 fine positioning: After the ground knife cover is opened, the image is collected by the depth camera 206 and the endoscopic probe, and the concentricity and relative angle adjustment between the floating operation cylinder 322 and the operation head are realized in cooperation with the robot and the frame assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com