Multi-screen and multi-category-diamond ordered material distribution equipment and method

A diamond and stencil technology, applied in metal processing equipment, grinding/polishing equipment, grinding devices, etc., to achieve the effects of avoiding manual errors, convenient combination and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the embodiments of the present invention will be described below with reference to the accompanying drawings.

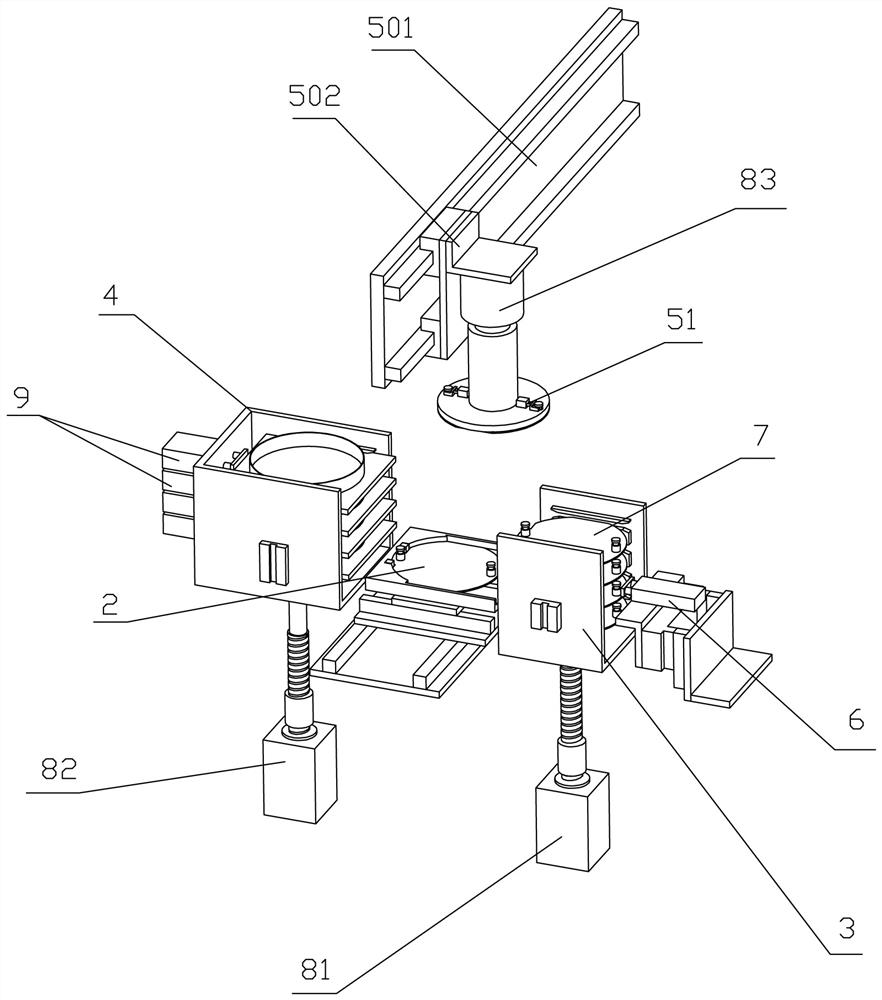

[0033] refer to Figure 1 to Figure 3 , a multi-stencil multi-type diamond orderly distributing device, comprising a distributing frame 1, the distributing frame 1 is provided with a stencil grasping and positioning seat 2, and the two sides of the stencil grasping and positioning seat 2 are respectively provided with a stencil storage The box 3 and the diamond storage bin 4, the center of the grid grab positioning seat 2, the grid storage box 3 and the diamond storage bin 4 are located on the same straight line. A plurality of mesh plates 7 are placed at intervals from top to bottom in the mesh storage box 3 , and several diamond bins 41 are placed at intervals from top to bottom in the diamond storage bin 4 . One side of the net plate storage box 3 is provided with a net plate pushing mechanism for pushing the net plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com