Steel structure steel pipe cutting device with automatic cleaning function

A technology for automatic cleaning and cutting devices, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc. It can solve the problems of unfavorable cleaning and recycling, metal debris that affects the health of workers, etc., and achieves convenient recombination, Reduce the workload and avoid the effect of splashing around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

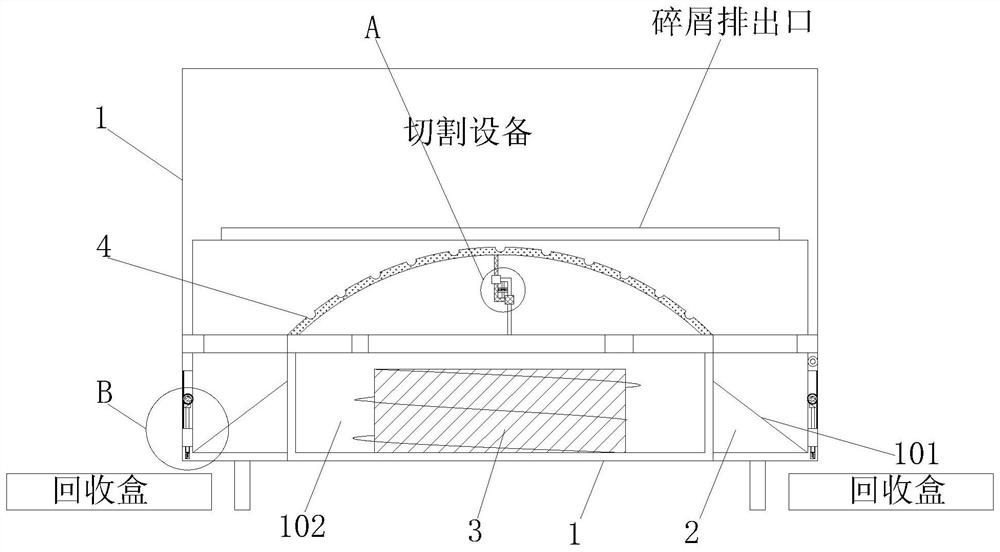

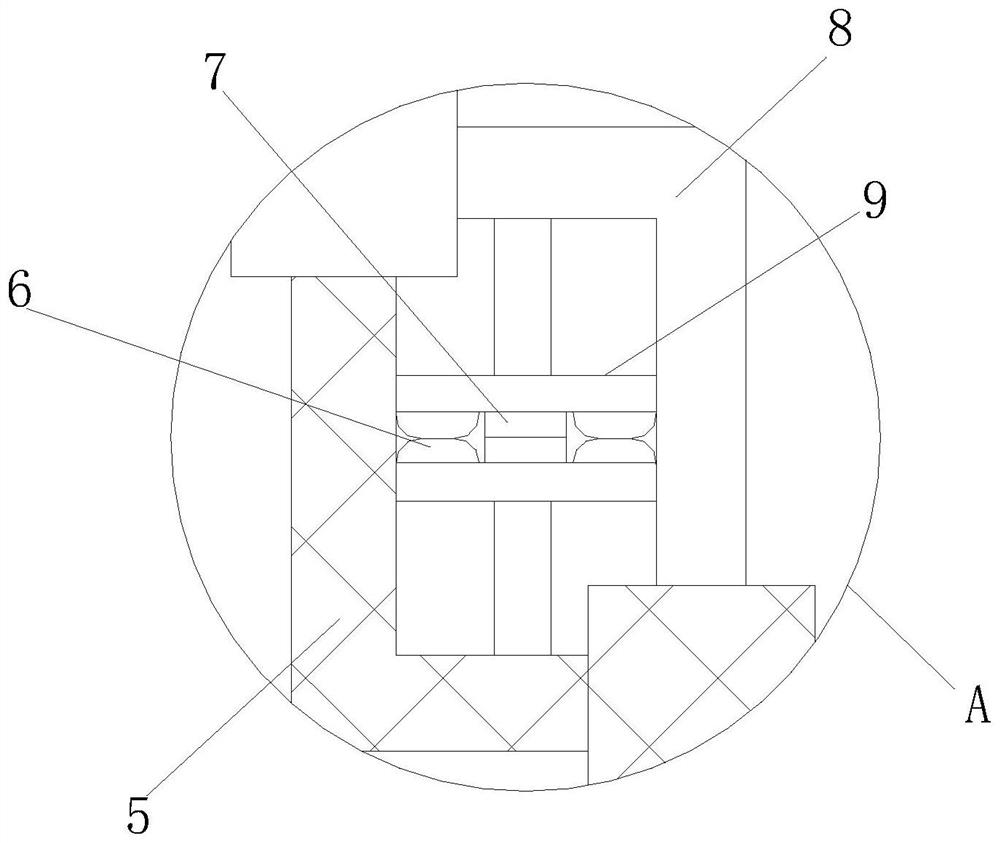

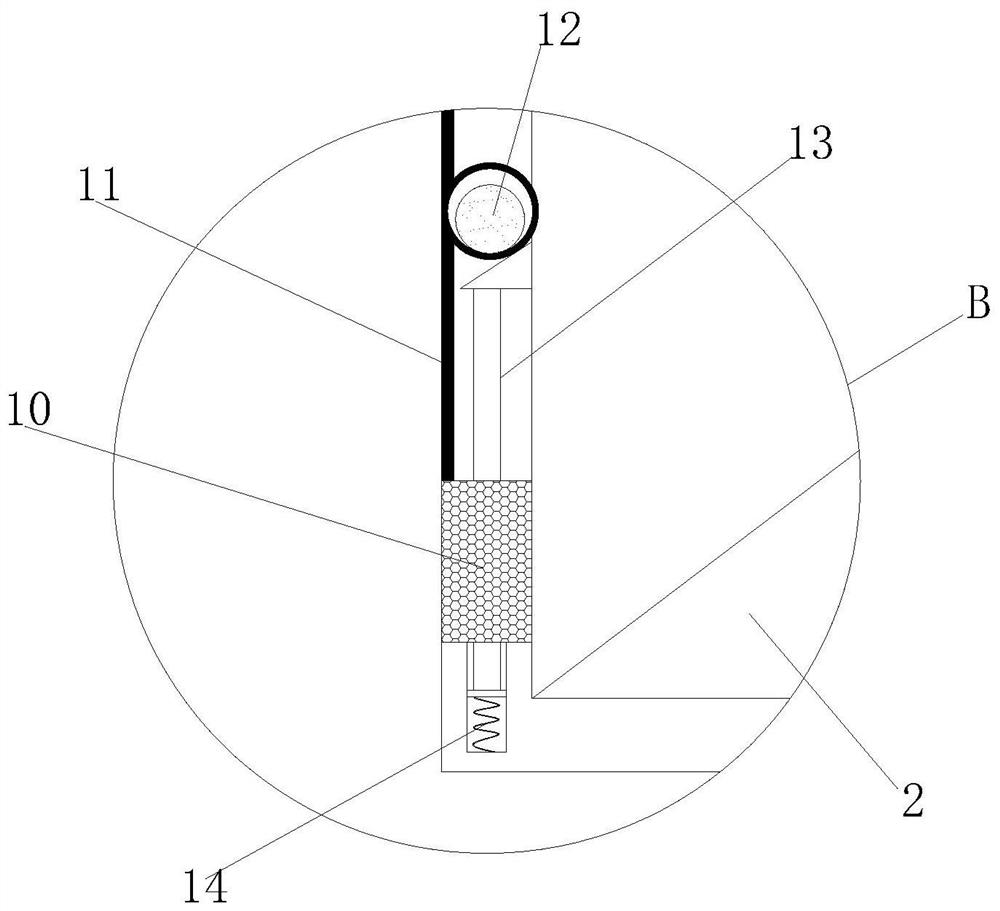

[0040] see figure 1 with figure 2 , a steel structure steel pipe cutting device with automatic cleaning function, comprising a recovery box 1, the bottom end of the recovery box 1 is fixedly connected with a cutting box, and the inside of the recovery box 1 is provided with a recovery groove 101 and an accommodation chamber 102, and the interior of the accommodation chamber 102 The top end is provided with an attachment shed 4, the inner top end of the attachment shed 4 is fixedly connected with a first "L"-shaped rod 5, the outer top end of the accommodating chamber 102 is fixedly connected with a second "L"-shaped rod 8, and the first "L"-shaped rod 5 and one end of the second "L"-shaped rod 8 are fixedly connected with a sleeve, and the sleeve is engaged with the first "L"-shaped rod 5 and the second "L"-shaped rod 8 respectively, and the first "L"-shaped rod 5 and one end of the second "L"-shaped rod 8 are fixedly connected with a "T"-shaped plate 9, one side of the "T"-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com