High-speed stamping die for producing metal parts

A technology of high-speed stamping and metal parts, applied in the field of stamping dies, can solve the problems of material grabbing, affecting the quality of stamping buttons, and the inability to perform targeted repair and maintenance of inserts, so as to stabilize the center point and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

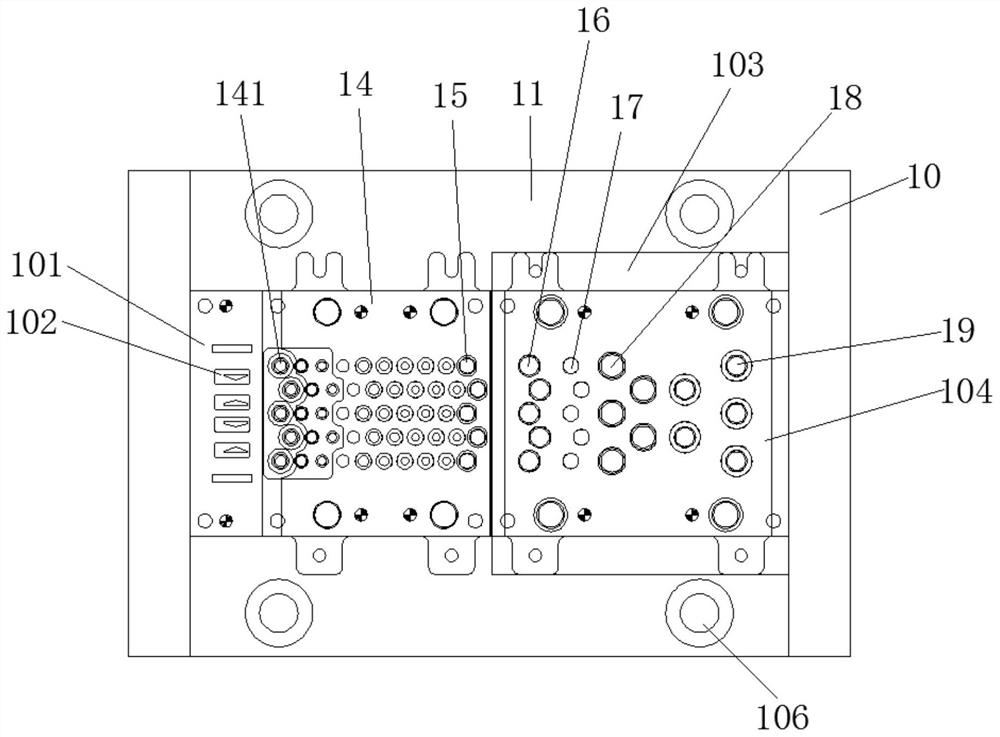

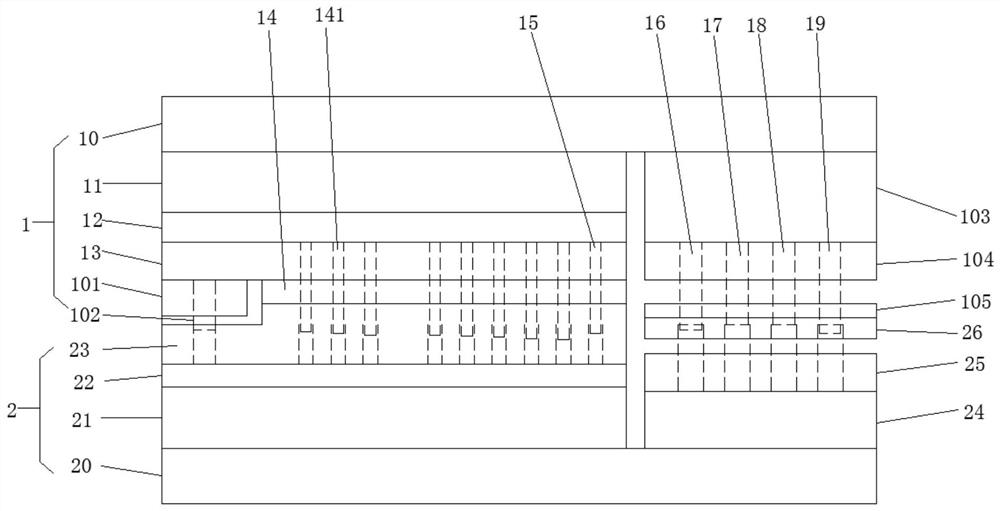

[0033] see figure 1 and figure 2 , in an embodiment of the present invention, a high-speed stamping die for producing metal parts includes an upper die 1 and a lower die 2, the upper die 1 is stacked on the top surface of the lower die 2 in parallel, and the upper die 1 includes There are an upper distribution area, an upper punching area, and an upper cutting area arranged from left to right, the upper distribution area includes a cutting knife 102 (for dividing raw materials), and the upper punching area includes a To the right and the stretching needle 141 (for stretching the shape of the button) arranged from small to large in diameter, the punching needle 15 that is located at the right end, the described upper cutting area includes the needles for opening that are arranged from left to right. The first insert 16 for the window, the second insert 17 for shaping, the third insert 18 for pressing the mark, and the fourth insert 19 for the notch, the lower mold 2 includes ...

Embodiment 2

[0041] In the embodiment of the present invention, the third insert 18 includes a female model and a male model, and the top surface of the female model is provided with a concave surface, which is used to engrave convex on the top surface of several male models. The surface of the male model is used in the product production line. The surface of the product in the production line is engraved with a concave surface corresponding to the male model. The female model and the male model are both made of oil steel. The oil steel is quenched And after low-temperature tempering, it has more excess carbides and higher hardness and wear resistance than chromium steel (Cr12) and 9SiCr steel, so that the male model without heat treatment and the heat-treated hardened female model form about 45 degrees The hardness is poor, which is beneficial to the tapered surface of the male model to be formed, and to protect the concave pattern on the surface of the female model, so that the female mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com