Pushing device for tea processing and use method

A pushing device and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems that the effect of tea roasting cannot be guaranteed, and tea is prone to sun blocking and sun blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

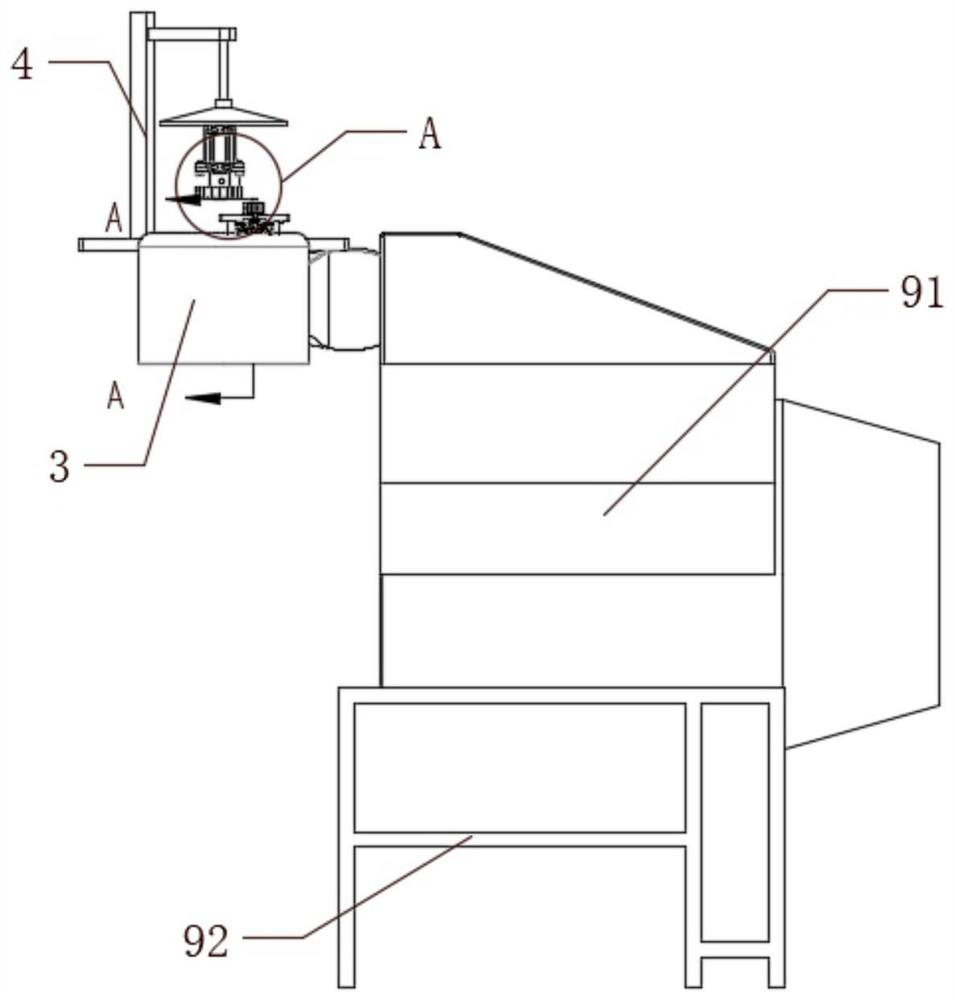

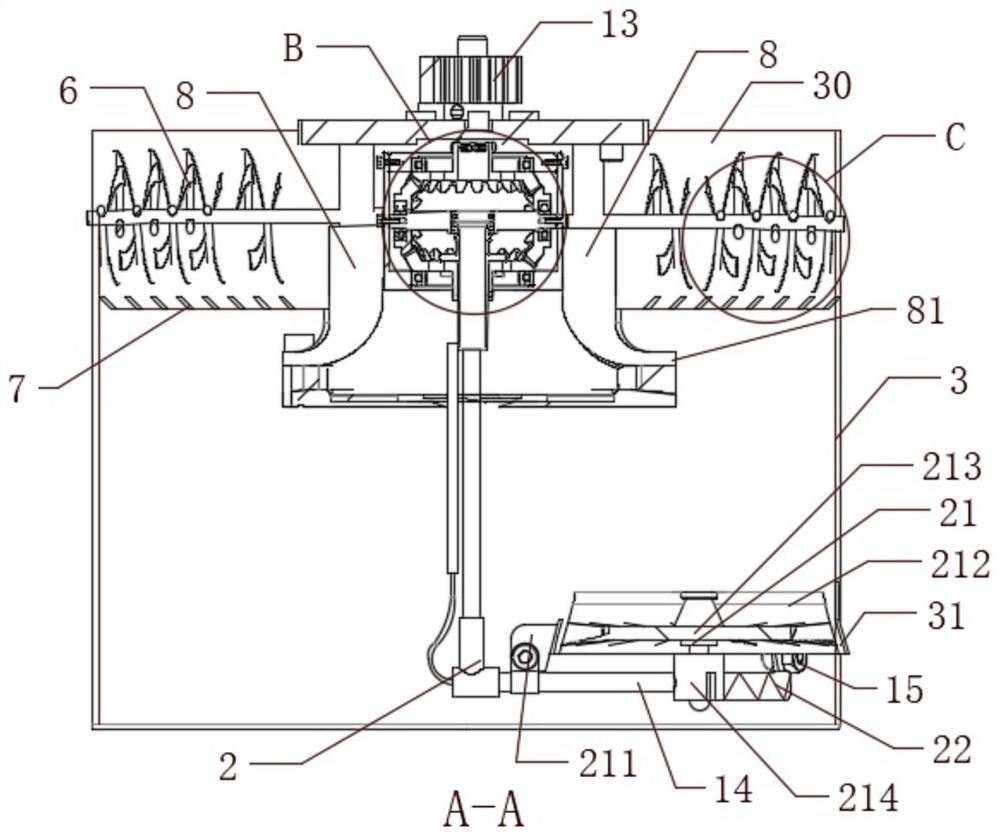

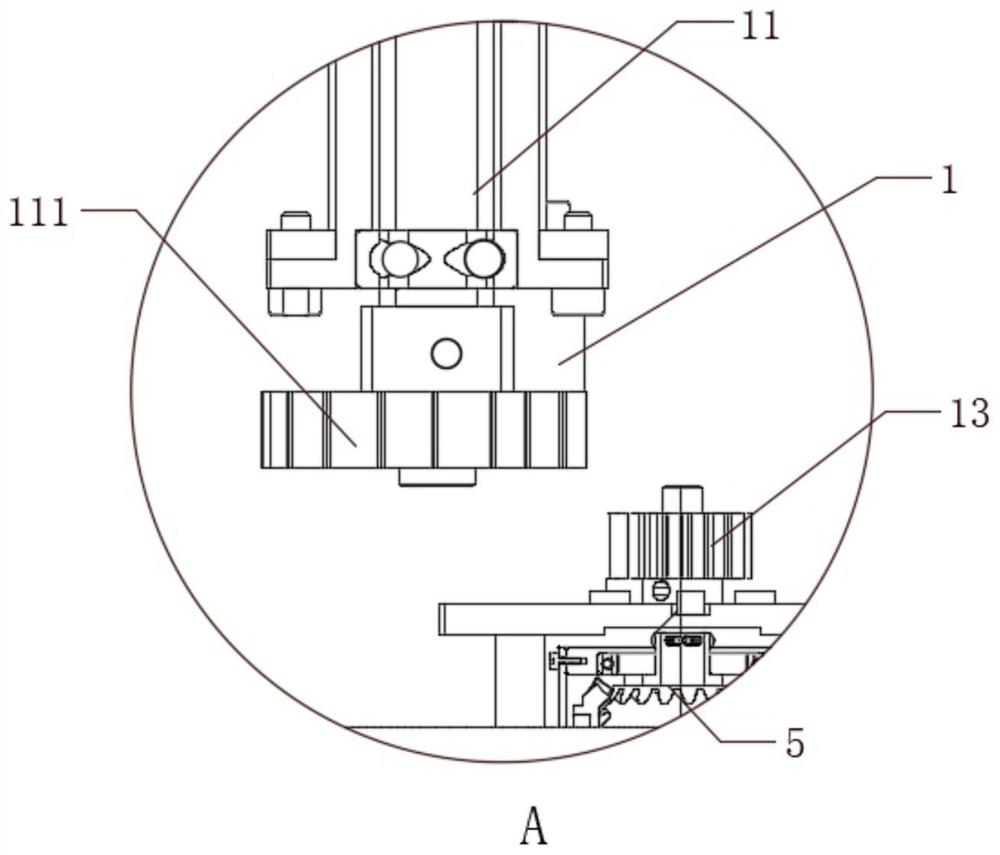

[0047] like Figure 1-6 As shown, a tea processing feeding device of the present invention includes a push-drive portion 1, a push-based execution unit 2, a pretreative housing 3, a push driving unit 1, and a push executive execution unit 2 are provided in a pretreatment. The inside of the housing 3 is connected to the upper portion of the push-up housing 3, and the shorter active portion 2 is active with the lower end of the pusher driving portion 1, and the pusher driving portion 1 drives the pusher 2 in the pre- The internal rotation of the housing 3 is processed. In the outer side of the killing device 91, the tea leaf is started to be added to the pretreatment housing 3, and the pre-dispersion of the tea is achieved, and the discredible tea is agitated at the bottom of the pretreatment housing 3, and The transport cavity 9 is entered in an orderly manner by the push outlet 31 to avoid obscuring the tea in the transport channel.

[0048] The push-out port 31 is opened on the pr...

Embodiment 2

[0052] This embodiment is further improved as the above example, such as Figure 1-6 As shown, a tea processing feeding device of the present invention includes a push-drive portion 1, a push-based execution unit 2, a pretreative housing 3, a push driving unit 1, and a push executive execution unit 2 are provided in a pretreatment. The inside of the housing 3 is connected to the upper portion of the push-up housing 3, and the shorter active portion 2 is active with the lower end of the pusher driving portion 1, and the pusher driving portion 1 drives the pusher 2 in the pre- The internal rotation of the housing 3 is processed. In the outer side of the killing device 91, the tea leaf is started to be added to the pretreatment housing 3, and the pre-dispersion of the tea is achieved, and the discredible tea is agitated at the bottom of the pretreatment housing 3, and The transport cavity 9 is entered in an orderly manner by the push outlet 31 to avoid obscuring the tea in the transpo...

Embodiment 3

[0059] This embodiment is further improved as the above example, such as Figure 1-6As shown, a tea processing feeding device of the present invention includes a push-drive portion 1, a push-based execution unit 2, a pretreative housing 3, a push driving unit 1, and a push executive execution unit 2 are provided in a pretreatment. The inside of the housing 3 is connected to the upper portion of the push-up housing 3, and the shorter active portion 2 is active with the lower end of the pusher driving portion 1, and the pusher driving portion 1 drives the pusher 2 in the pre- The internal rotation of the housing 3 is processed. In the outer side of the killing device 91, the tea leaf is started to be added to the pretreatment housing 3, and the pre-dispersion of the tea is achieved, and the discredible tea is agitated at the bottom of the pretreatment housing 3, and The transport cavity 9 is entered in an orderly manner by the push outlet 31 to avoid obscuring the tea in the transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com