A method and device for improving the temperature uniformity of metal plate resistance heating by using gallium

A resistance heating, metal plate technology, applied in ohmic resistance heating parts, ohmic resistance electrodes, improving energy efficiency, etc., can solve the problems of uneven temperature distribution of steel plates, inconsistent deformation ability of steel plates, and different sizes, and achieve good results. Conductive performance, reduce the overall temperature difference, and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

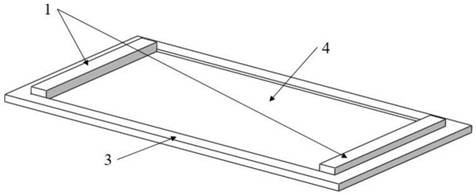

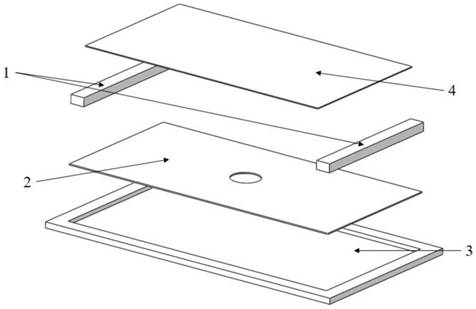

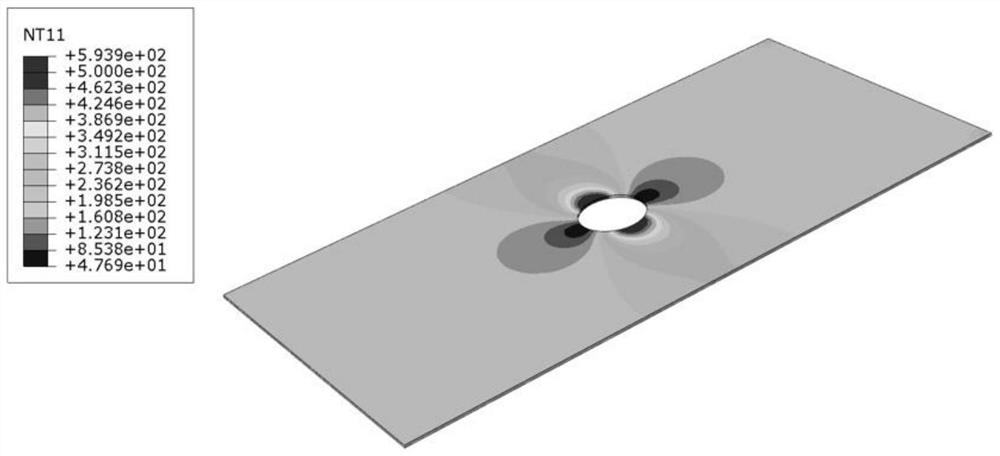

[0029] Combine below Figure 1-6 Describe this embodiment, a method of using gallium to improve the temperature uniformity of metal plate resistance heating, including a conductive metal plate 2, a mold 3, a pressure plate 4 and two electrodes 1, gaps and holes between the conductive metal plate 2 and the mold 3 Filled with liquid gallium, the pressure plate 4 is pressed on the conductive metal plate 2; it can be filled into the gaps and holes between the conductive metal plate 2 and the mold 3 through the liquid metal gallium, which ensures good electrical conductivity of the contact interface and reduces the The skin effect effectively compensates the area with a small cross-sectional area of the irregular conductive metal plate 2, so that the cross-sectional area of the conductive metal plate 2 in the direction of the current is almost the same, thus ensuring that the conductive metal plate 2 is heated at any time during the heating process. The current density of the c...

specific Embodiment approach 2

[0030] Combine below Figure 1-6 Describe this embodiment mode, this embodiment mode will further describe Embodiment 1, and described this method comprises the following steps:

[0031] Step 1: Add a sufficient amount of metal gallium into the mold 3, and heat the mold 3 so that the temperature of any part of the inner groove of the mold 3 exceeds 30°C. At this time, the metal gallium exists in liquid form; the melting point of gallium is 29.8°C The mold 3 can be heated with a heat gun, etc., to ensure that the temperature of the mold 3 is higher than the melting point of metal gallium, so that the metal gallium exists in a liquid state before the conductive metal plate 2 is placed into the groove of the mold 3;

[0032] Step 2: Put the conductive metal plate 2 into the groove of the mold 3, adjust the position of the conductive metal plate 2 so that the conductive metal plate is located in the center of the groove of the mold 3; check whether the liquid gallium completely fi...

specific Embodiment approach 3

[0036] Combine below Figure 1-6 Illustrate this embodiment, this embodiment will further illustrate Embodiment 2, the length, width and depth of the inner groove of the mold 3 are respectively greater than the length, width and height of the conductive metal plate 2; the length and width of the groove of the mold 3 Respectively greater than the length and width of the conductive metal plate 2, one is to ensure that the thermal expansion of the conductive metal plate 2 during the heating process will not affect the mold 3, so that the conductive metal plate 2 can be fully deformed; the other is to ensure that the liquid metal gallium can be The gap is completely filled; the depth of the groove of the mold 3 is greater than the thickness of the conductive metal plate 2, so that excess liquid metal gallium can be stored in the groove of the mold 3 without overflowing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com