Automatic loading, unloading, shaping and installing integrated robot for IGBT chip

An automatic loading and unloading and robot technology, applied in semiconductor/solid-state device manufacturing, conveyor objects, transportation and packaging, etc., can solve problems affecting processing efficiency, chip positioning error, high labor cost, etc., and achieve the effect of solving chip positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

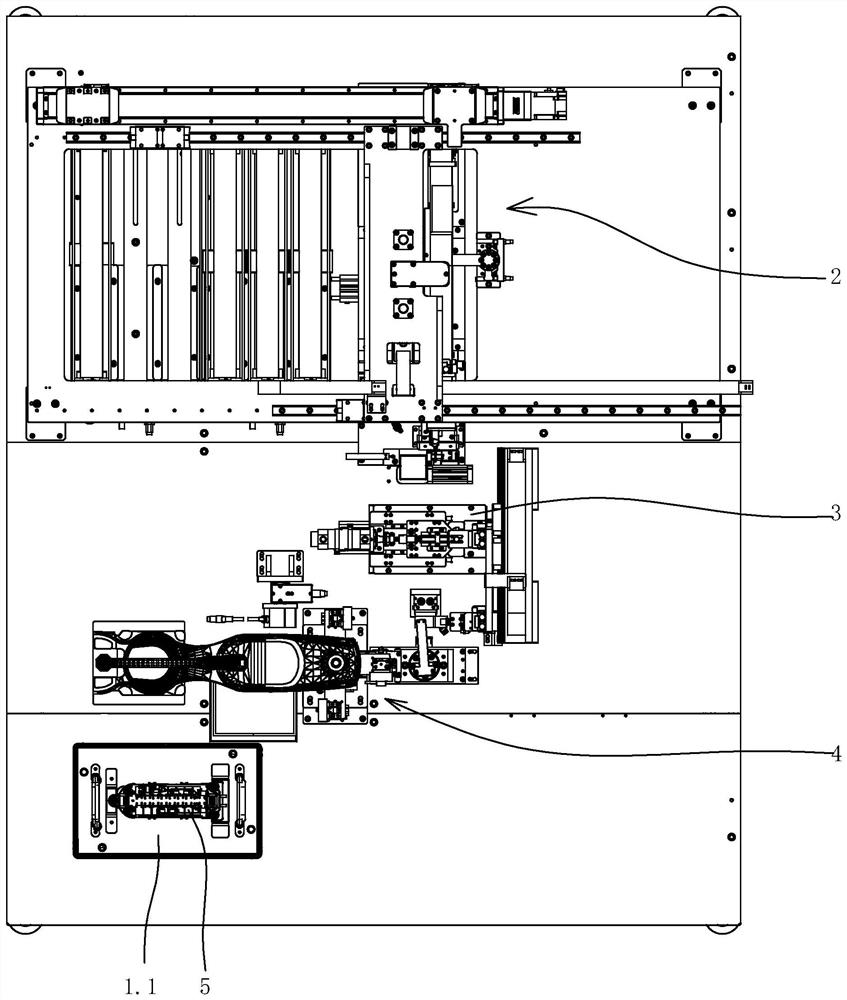

[0085] Specific embodiment one: as figure 1 , figure 2 , image 3As shown, an integrated robot for automatic loading, unloading, shaping and installation of IGBT chips includes a frame, a tray 1.1, an automatic chip unloading machine 2, a chip shaping station 3 and a chip mounting station 4. The tray is used to place the IGBT module 5, and the tray is provided with vertically distributed positioning pins for positioning the IGBT module. The IGBT module is placed on the tray. The IGBT module has a process hole, and the process hole is matched with the positioning pin. In this embodiment, the tray is fixedly placed on the rack.

[0086] The chip automatic blanking machine is used to output the chips in the chip material tube one by one, so as to realize the automatic chip blanking output of the chip material tube; in this embodiment, the chip automatic blanking machine is an automatic chip blanking machine in the prior art .

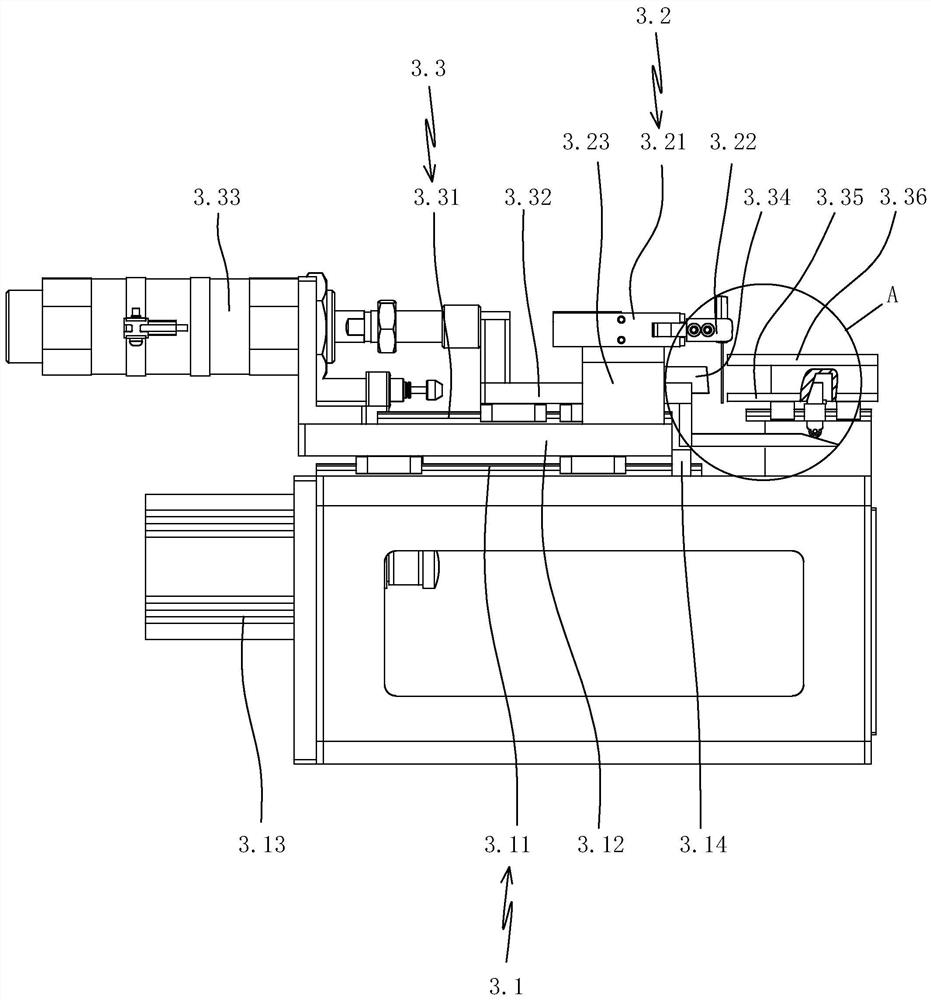

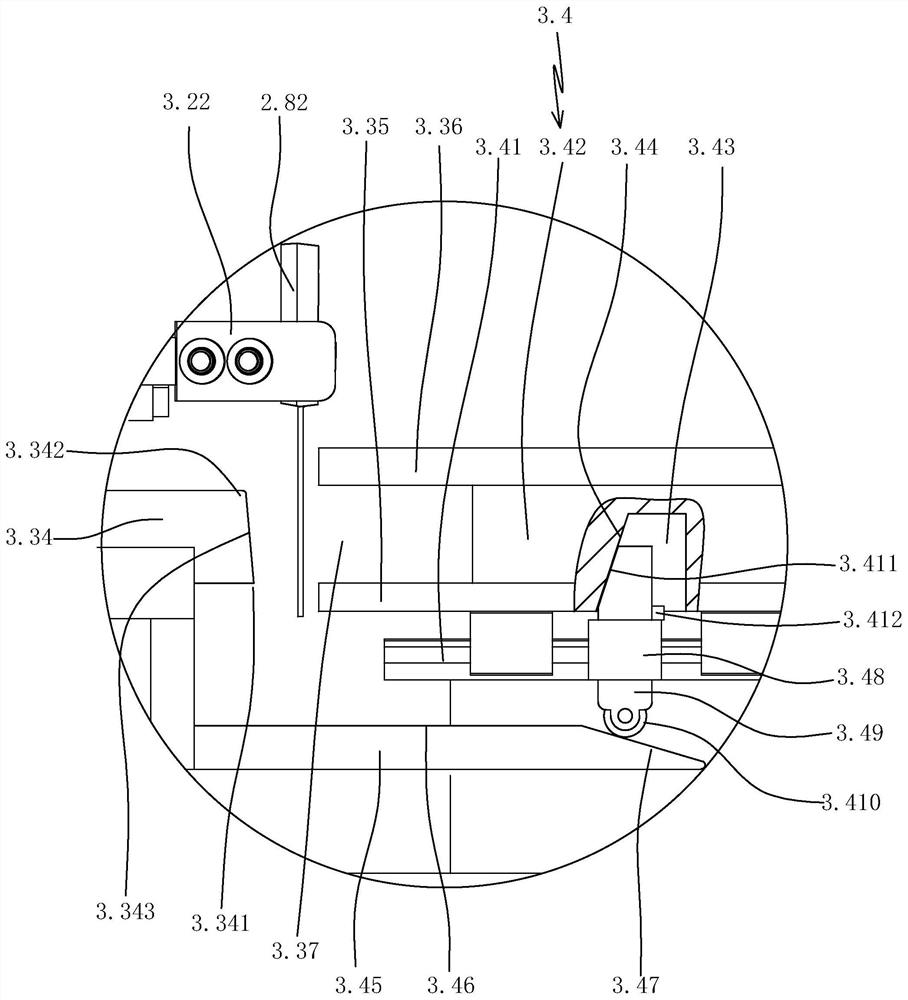

[0087] The chip shaping station includes a chi...

specific Embodiment 2

[0109] Specific embodiment two, all the other structures of this embodiment refer to specific embodiment one, and its difference is:

[0110] Such as Figure 4 As shown, the chip automatic unloading machine includes a first material tube grabbing manipulator 2.2, a second material tube grabbing manipulator 2.4, a chip material warehouse 2.1, a chip material tube direction adjustment device 2.3, a material pushing device 2.5, and a material tube rotating device 2.6 2.7 with chip output device.

[0111] The chip magazine is used to place chip tubes. Such as Figure 5 As shown, the chip material tube 2.8 includes a material tube 2.81 with a rectangular cross section and a number of chips 2.82 sequentially distributed in the material tube. The chip includes a chip body 2.821 and several pins 2.822. The center of gravity of the chip is distributed in the middle of the chip body. The pins of the chips are distributed on the same side of the chip, and the pins of the chips in the...

specific Embodiment 3

[0131] Specific embodiment three, all the other structures of this embodiment refer to specific embodiment three, and its difference is:

[0132] Such as Figure 9 As shown, the chip mounting station of this embodiment includes a loading station 4.3, a detection station 4.4, a blanking station, a rotating platform 4.1 and a platform rotating drive device arranged on the frame, and the platform rotating drive device is used for Drive the rotating platform to rotate. In this embodiment, the platform rotating driving device is a driving motor or a rotating cylinder. The rotary platform is provided with four chip positioning stations 4.2 evenly distributed around the circumference of the rotary axis of the rotary platform. Each chip positioning station includes a chip positioning block 4.21 and a clamping cylinder 4.22 arranged on the upper surface of the rotary platform. The clamping cylinder is used for clamping and positioning the chip placed on the chip positioning block. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com