Image pickup lens, image pickup apparatus, and mobile terminal

A technology of camera lens and camera device, which is applied in the field of camera lens, and can solve problems such as large changes in refractive index and temperature changes, large changes in image point positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

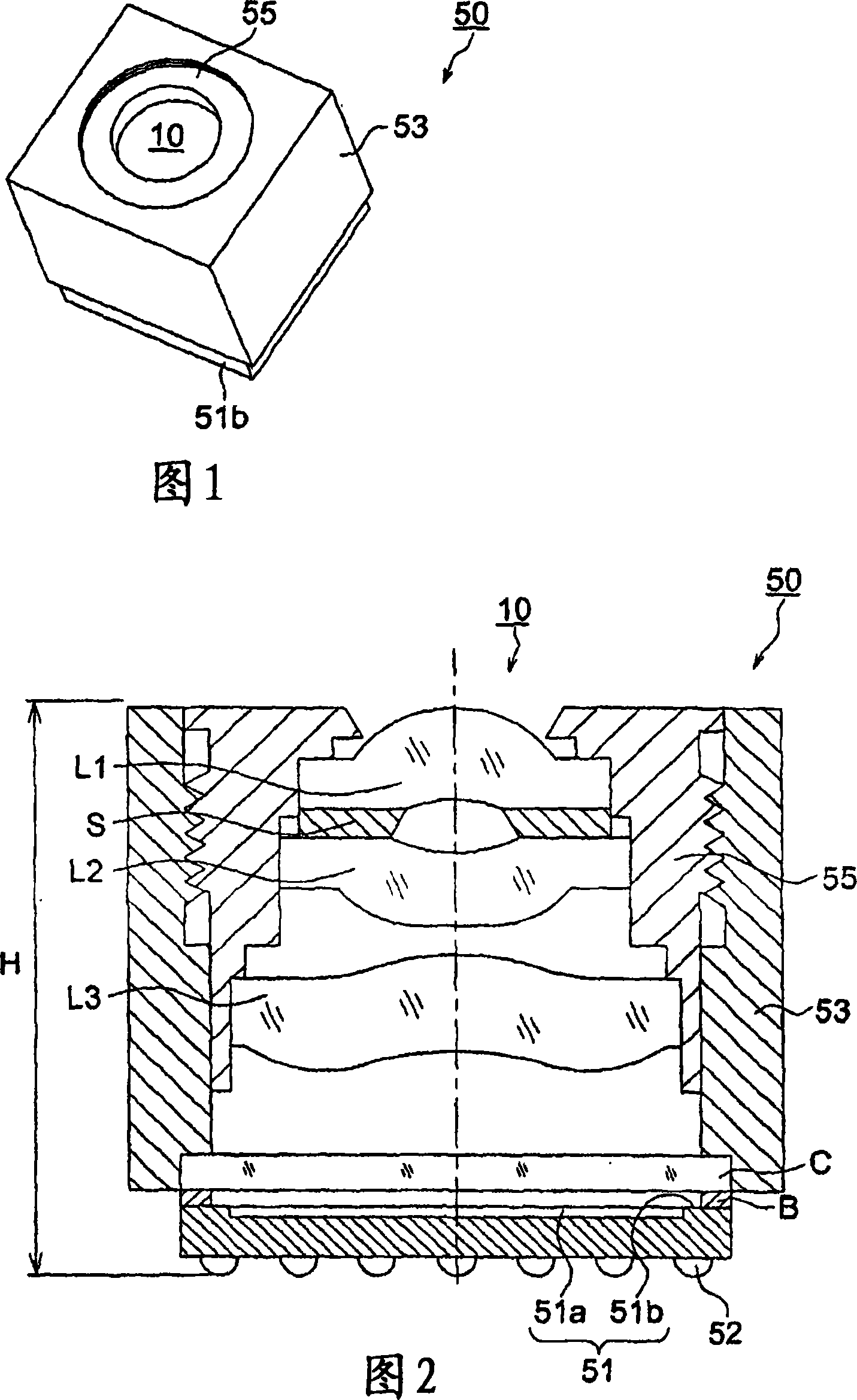

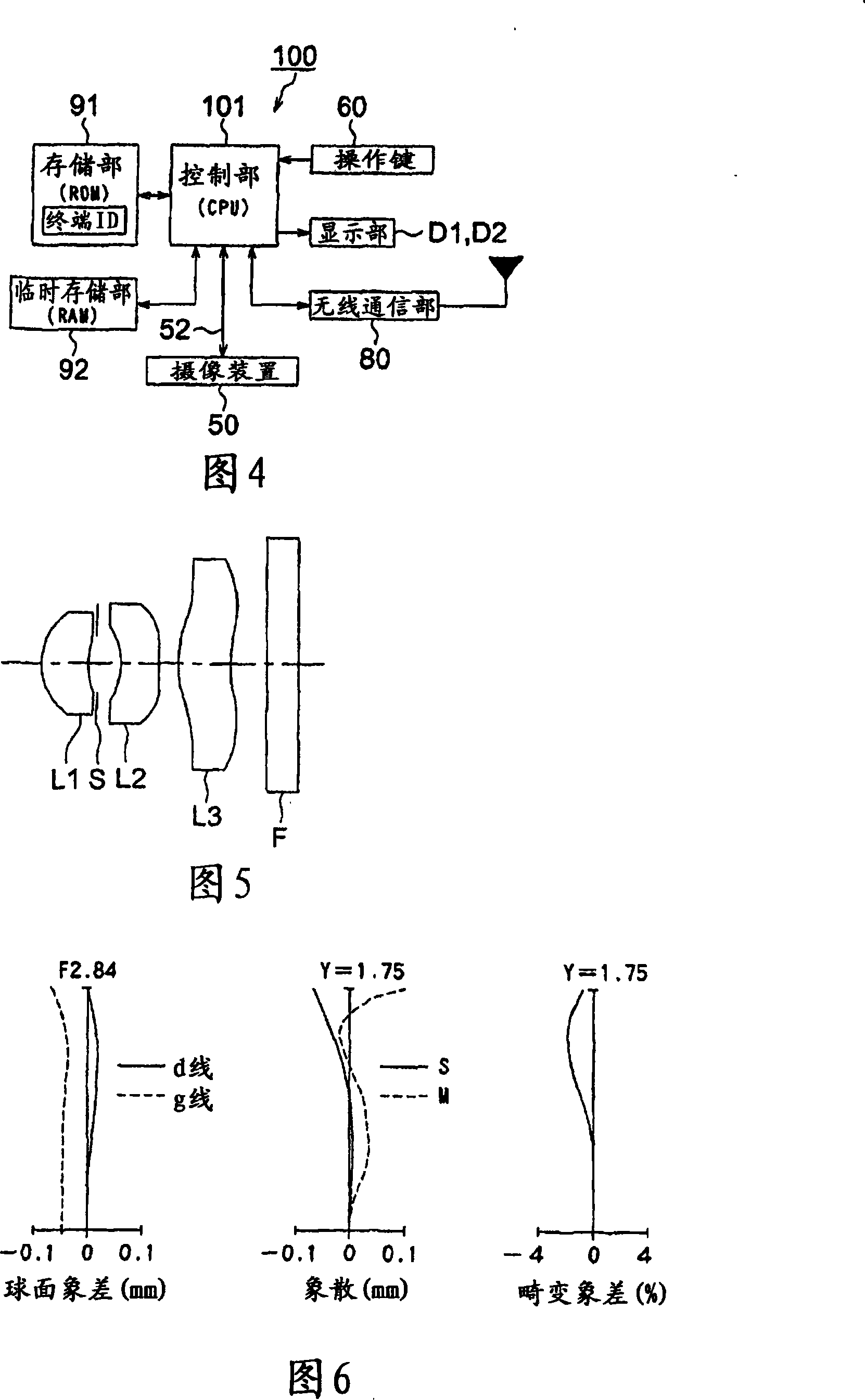

[0176] The following (Table 3) and (Table 4) show the lens data of the imaging lens of Example 1. The imaging lens shown in Embodiment 1 is composed of a first lens with maximum positive refractive power, a second lens with negative refractive power, and a third lens with positive refractive power. The first lens is a glass lens, and the second and third lenses are plastic lenses made of curable resin with an allyl ether structure with a glass transition temperature (Tg) of 300°C or higher.

[0177] [table 3]

[0178] (Example 1)

[0179] f1=2.70 fB=0.90 F=2.84 Y=1.75

[0180] Surface number R(mm) D(mm) Nd vd

[0181] 1 0.878 0.69 1.58313 59.4

[0182] 2 1.504 0.07

[0183] Aperture ∞ 0.30

[0184] 3 -1.462 0.56 1.51300 55.9

[0185] 4 -5.958 0.25

[0186] 5 1.074 0.67 1.51300 55.9

[0187] 6 1.720 0.30

[0188] 7 ∞ 0.40 1.51633 64.1

[0189] 8 ∞

[0190] [Table 4]

[0191] Aspheric coefficient

[0192] side 1

[0193] K=2.64770E-01

[0194] A4=-2.02470E-02

...

Embodiment 2

[0237] The following (Table 5) and (Table 6) show the lens data of the imaging lens of Example 2. The imaging lens shown in Embodiment 2 is composed of a first lens having the largest positive refracting power, a second lens having positive refracting power, and a third lens having negative refracting power. The first lens is a glass lens, and the second and third lenses are plastic lenses made of curable resin with an allyl ether structure with a glass transition temperature (Tg) of 300°C or higher.

[0238] [table 5]

[0239] (Example 2)

[0240] f1=2.70 fB=0.08 F=2.84 Y=1.75

[0241] Surface number R(mm) D(mm) Nd vd

[0242] 1 1.156 0.56 1.58313 59.4

[0243] 2 3.961 0.07

[0244] Aperture ∞ 0.51

[0245] 3 -0.880 0.47 1.51300 55.9

[0246] 4 -0.804 0.19

[0247] 5 3.640 0.62 1.51300 55.9

[0248] 6 1.444 0.50

[0249] 7 ∞ 0.40 1.51633 64.1

[0250] 8 ∞

[0251] [Table 6]

[0252] Aspheric coefficient

[0253] side 1

[0254] K=2.04510E-01

[0255] A4=-2.215...

Embodiment 3

[0302] The following (Table 7) and (Table 8) show the lens data of the imaging lens of Example 3. The imaging lens shown in Embodiment 3 is composed of a first lens with the largest positive refraction power, a second lens with positive refraction power, and a third lens with negative refraction power. The first lens is a glass lens, and the second lens and the third lens are plastic lenses formed of an acrylic curable resin having a glass transition temperature (Tg) of 270° C. or higher.

[0303] [Table 7]

[0304] Example 3

[0305] f1=2.70 fB=0.18 F=2.84 Y=1.75

[0306] Surface number R(mm) D(mm) Nd vd

[0307] 1 1.272 0.59 1.58913 61.2

[0308] 2 23.753 0.04

[0309] Aperture ∞ 0.41

[0310] 3 -0.915 0.66 1.52700 53.7

[0311] 4 -0.785 0.27

[0312] 5 41.191 0.47 1.52700 53.7

[0313] 6 1.444 0.40

[0314] 7 ∞ 0.40 1.51630 64.1

[0315] 8 ∞ 0.18

[0316] [Table 8]

[0317] Aspheric coefficient

[0318] side 1

[0319] K=1.4238E-02

[0320] A4=-4.1089E-02

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com