A Hydrogen Combustor Based on Axial Vortex-to-column Mixing

A combustion chamber, axial technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problem of complex structure of transverse jet micro-mixing combustion chamber, difficulty in burning high-concentration hydrogen and pure hydrogen, high design and test costs, etc. problem, to achieve the effect of increasing the combustion power per unit volume, fast processing speed and cheap geometric shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, embodiments of the present disclosure will be described with reference to the accompanying drawings. It should be understood, however, that these descriptions are exemplary only

[0062] The terminology used herein is for the purpose of describing particular embodiments only and is not intended to limit the present disclosure. use here

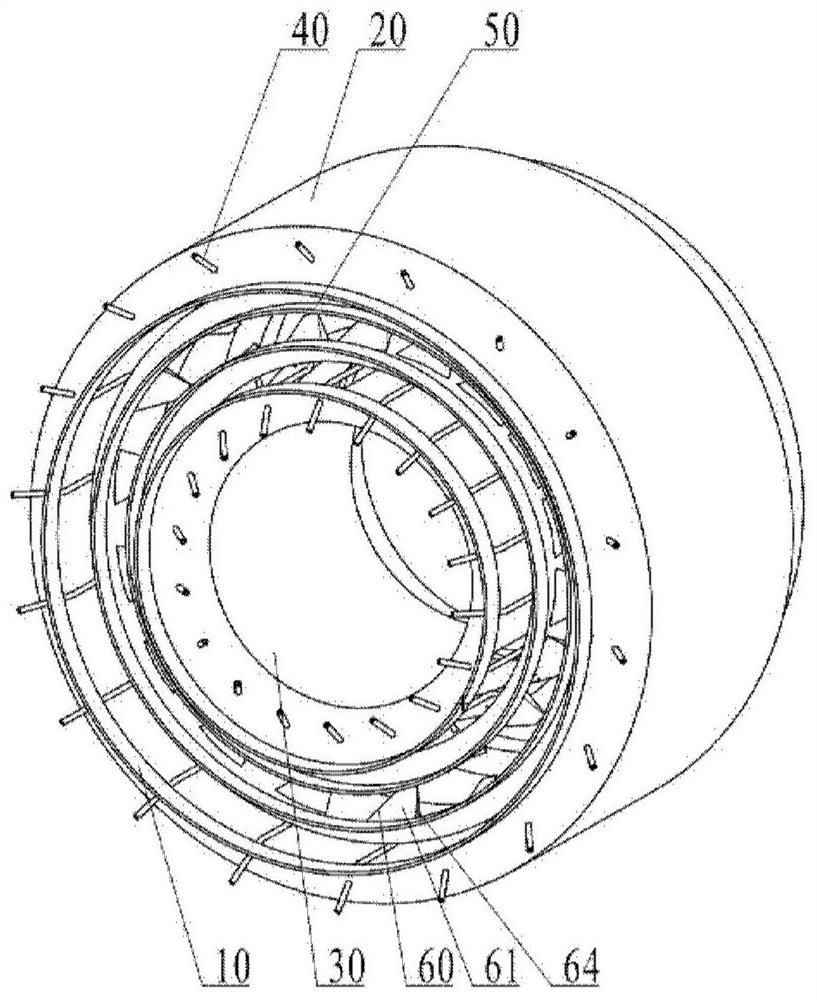

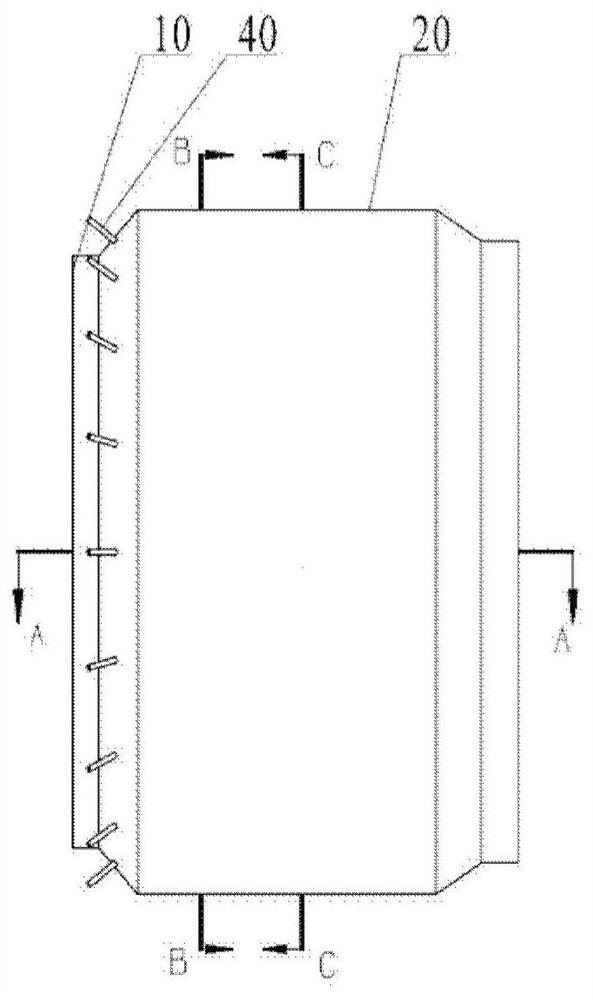

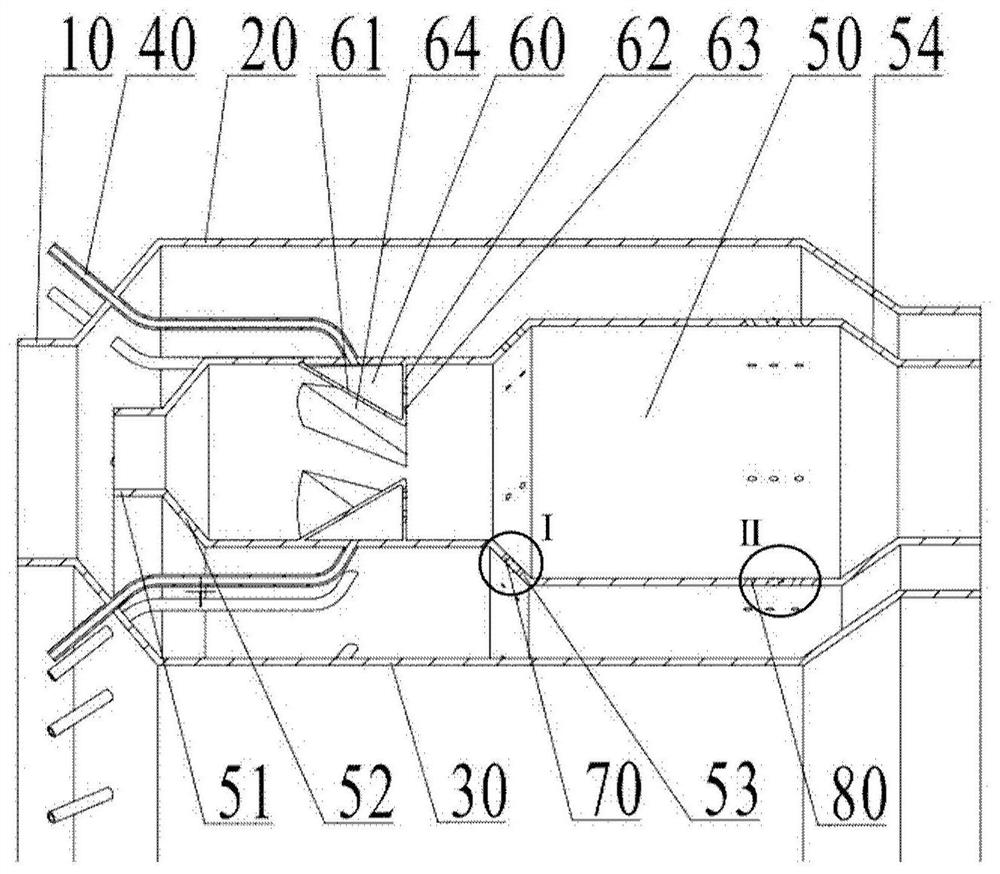

[0065] The present disclosure provides a blended hydrogen combustor based on an axial vortex row arrangement, as shown in FIGS. 1 to 3, comprising:

[0070] The above-mentioned trailing edge 62 includes at least one fuel hole 63. As shown in FIG. 9, the axis of the fuel hole 63 is parallel with the trailing edge 62.

[0072] The above-mentioned axial vortex generator 60 locally mixes the air axial vortex with the jet hydrogen fuel to realize diffusion combustion.

[0077] The above-mentioned circumferentially aligned arrangement enhances the blending effect, improves the combustion power per unit volume, and further reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com