Two-component dispensing valve, glue injection machine with same and use method of glue injection machine

A dispensing valve, two-component technology, applied in the field of dispensing valve, can solve the problems of increasing cleaning frequency, complex internal structure, affecting practicability, etc., and achieve the effect of improving use efficiency, improving production efficiency, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

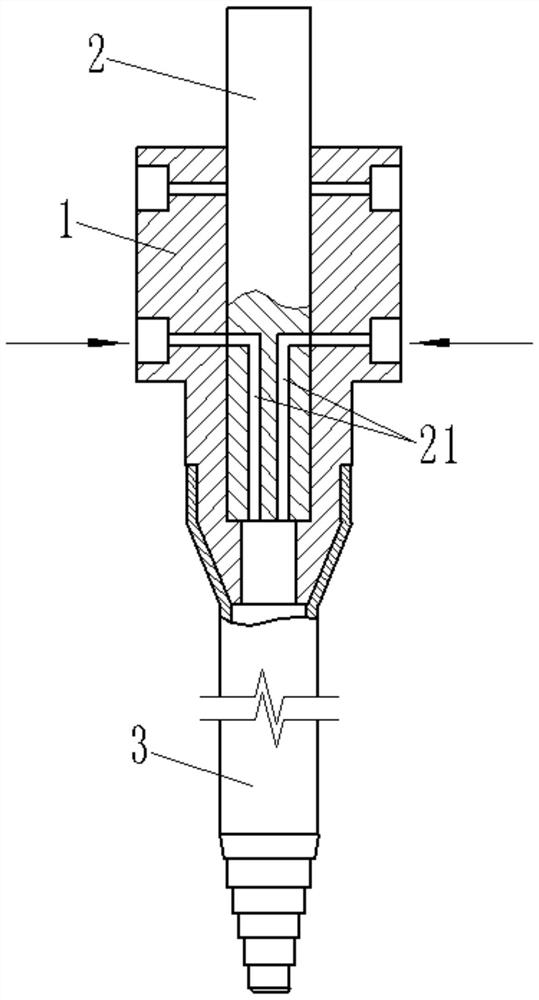

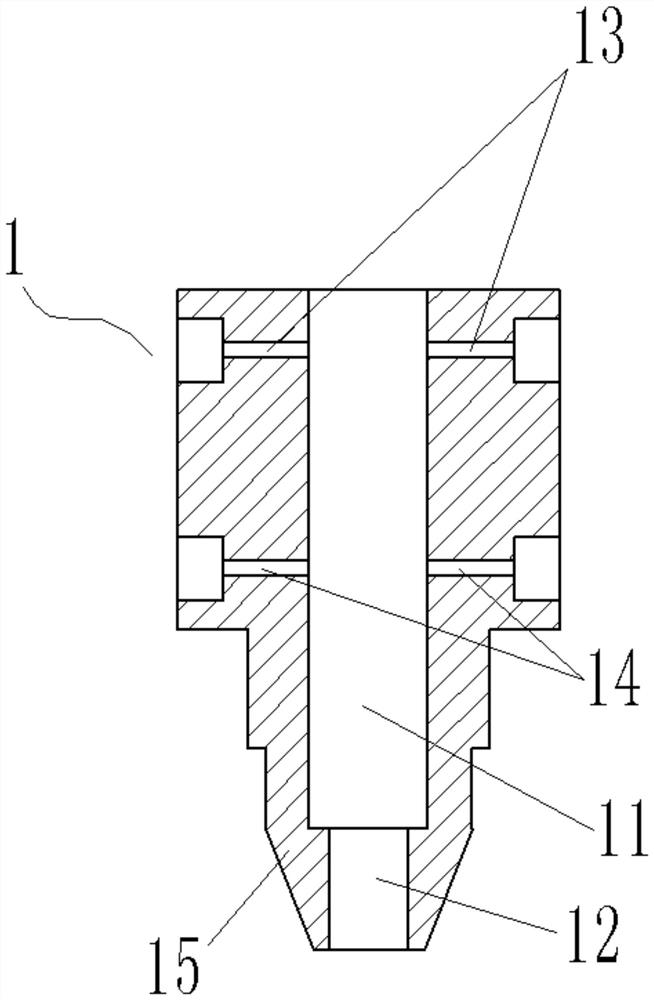

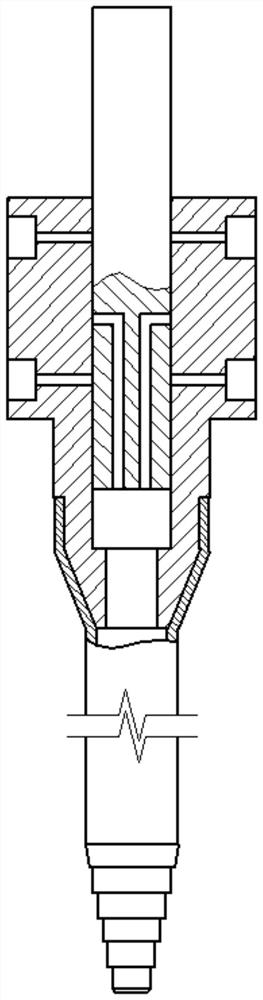

[0032] see Figure 1 ~ Figure 4 , the present invention provides a two-component dispensing valve, comprising: a valve body 1 and a valve stem 2; the lower end of the valve body 1 is provided with an integrated joint 15, and the joint 15 is used to seal the static mixing pipe 3; the valve body 1 is provided with a vertical and through sliding chamber 11; the side of the valve body 1 is provided with an air inlet 13 and a feeding hole 14 communicating with the sliding chamber 11 in sequence from top to bottom, the air inlet 13 and the feeding hole The number of 14 is 2 respectively; wherein, the air inlet 13 is used for inputting water and / or air;

[0033] The valve stem 2 here slides in a sealed manner in the sliding chamber 11. The bottom of the valve stem 2 is provided with a glue channel 21. One end of the glue channel 21 can match and communicate with the air inlet 13 and the feed hole 14, and the other end It is used to output glue; the number of glue channels 21 is 2; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com