Normal-temperature yoghourt and preparation method thereof

A room temperature, yogurt technology, applied in milk preparations, bacteria used in food preparation, dairy products, etc., can solve the loss of taste and particle integrity, the viscosity of the material should not be too high, and affect the heat transfer rate of the heating surface and the solid interface. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

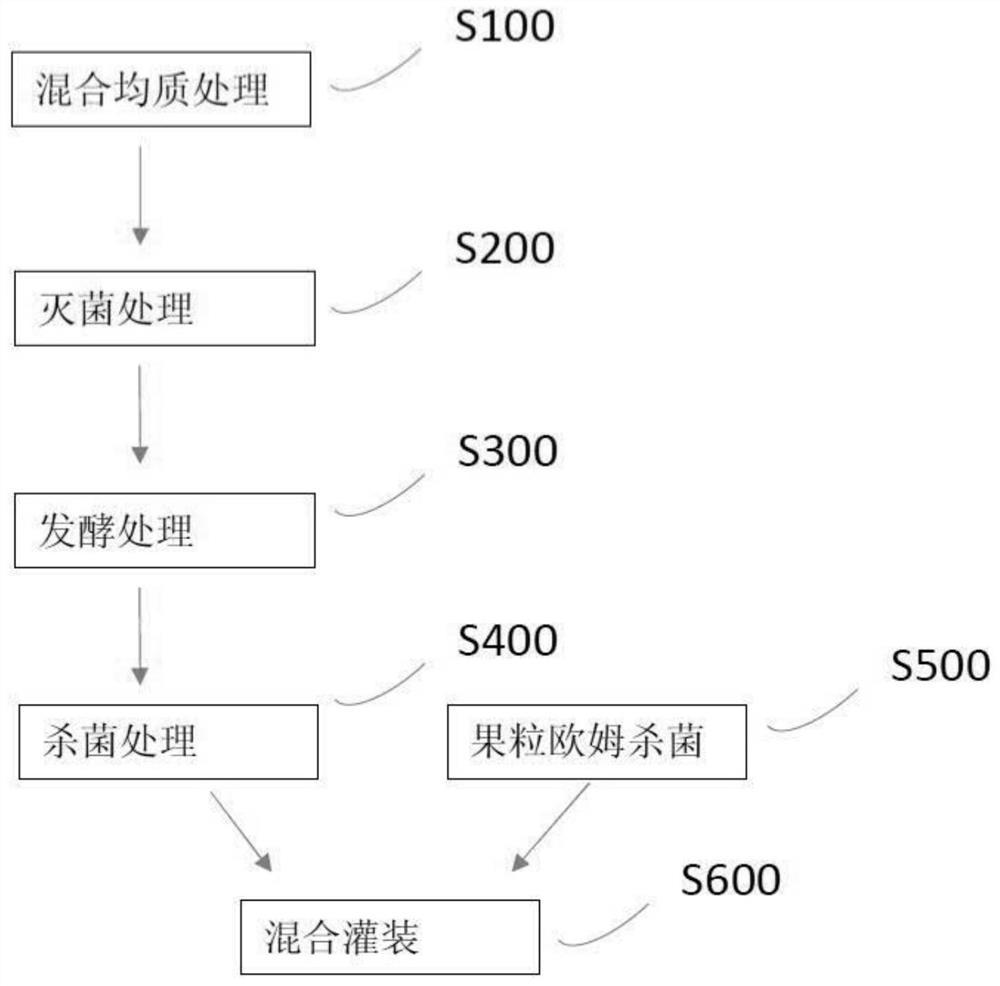

Method used

Image

Examples

Embodiment 1

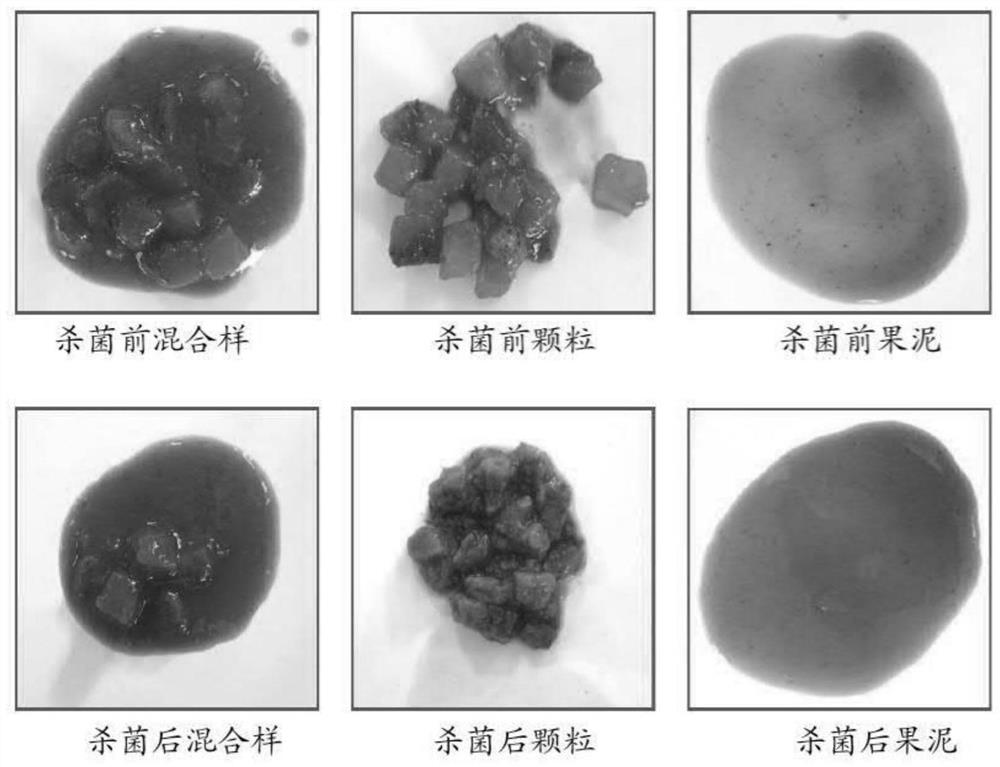

[0179] This example provides a method for producing normal-temperature yogurt with real strawberry grain taste.

[0180] 1. Preparation process of normal temperature yogurt base material:

[0181]

[0182]

[0183] 1. Use a high-speed shearing machine to disperse the stabilizer and white sugar into raw milk at 45°C;

[0184] 2. Mix concentrated milk protein powder with raw milk at 45°C for 15 minutes;

[0185] 3. Mix the mixture of 1 and 2 for 15 minutes, and dilute with raw milk;

[0186] 4. Homogenize after preheating to 55°C, and the homogenization pressure is 180bar;

[0187] 5. The sterilization treatment parameters are 95°C, 300s;

[0188] 6. Fermentation: Cool at 42°C and inoculate the starter;

[0189] 7. Demulsification cooling: Stir for 15 minutes, cool through a plate heat exchanger, and temporarily store the feed liquid until it is ready to be filled in a tank.

[0190] 2. Fruit preparation process:

[0191] 1. Fruit selection: choose 7 ripe strawberrie...

Embodiment 2

[0199] 1. Preparation process of normal temperature yogurt base material:

[0200]

[0201]

[0202] 1. Use a high-speed shearing machine to disperse the stabilizer and white sugar into raw milk at 45°C;

[0203] 2. Mix concentrated milk protein powder with raw milk at 45°C for 15 minutes;

[0204] 3. Mix the mixture of 1 and 2 for 15 minutes, and dilute with raw milk;

[0205] 4. Homogenize after preheating to 65°C, and the homogenization pressure is 200bar;

[0206] 5. The sterilization treatment parameters are 100°C, 200s;

[0207] 6. Fermentation: Cool at 42°C and inoculate the starter;

[0208] 7. Demulsification cooling: Stir for 15 minutes, cool through a plate heat exchanger, and temporarily store the feed liquid until it is ready to be filled in a tank.

[0209] 2. Fruit preparation process:

[0210] 1. Fruit selection: choose 6 ripe strawberries with pure color and no mechanical damage;

[0211] 2. Fruit dicing: Use a dicing machine to cut the fruit into ...

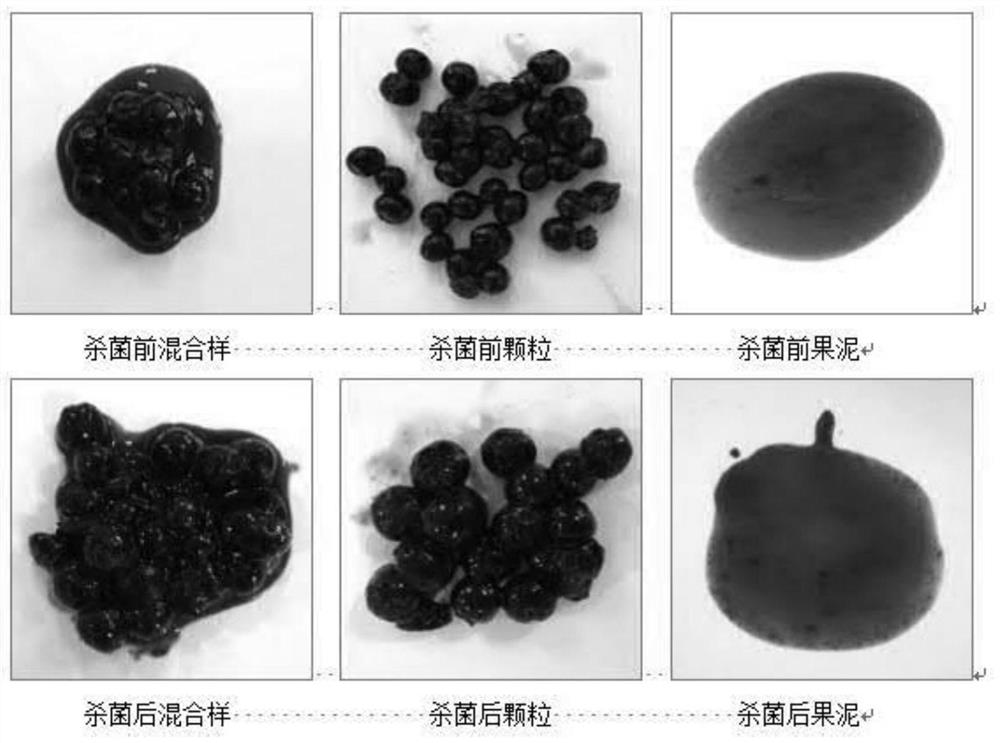

Embodiment 3

[0218] 1. Preparation process of normal temperature yogurt base material:

[0219] raw milk 805.6kg White sugar 70kg fruit 100kg Concentrated Milk Protein Powder 4.2kg stabilizer 20.2kg starter 100DCU Wherein the stabilizing agent is composed as follows: Hydroxypropyl Distarch Phosphate 19kg low ester pectin 0.4kg Diacetyl tartrate mono-diglycerides 0.8kg

[0220] 1. Use a high-speed shearing machine to disperse the stabilizer and white sugar into raw milk at 45°C;

[0221] 2. Mix concentrated milk protein powder with raw milk at 45°C for 15 minutes;

[0222] 3. Mix the mixture of 1 and 2 for 15 minutes, and dilute with raw milk;

[0223] 4. Homogenize after preheating to 80°C, and the homogenization pressure is 220bar;

[0224] 5. The sterilization treatment parameters are 120°C, 400s;

[0225] 6. Fermentation: Cool at 42°C and inoculate the starter;

[0226] 7. Demulsification cooling: Stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com