Heat dissipation structure and control method of power monitoring communication management machine

A technology of communication management machine and heat dissipation structure, which is applied in the field of heat dissipation structure and control of power monitoring communication management machine, which can solve the problems of loss of heat dissipation performance of management machine, adverse effects of normal work, and low heat dissipation efficiency, so as to facilitate heat dissipation and cooling , Avoid excessive local temperature and improve the effect of heat dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

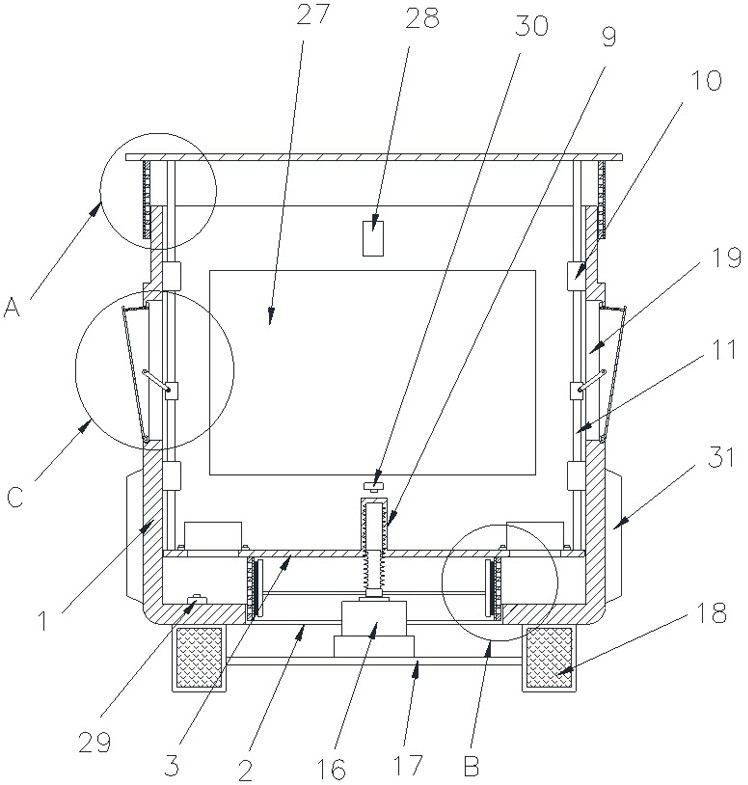

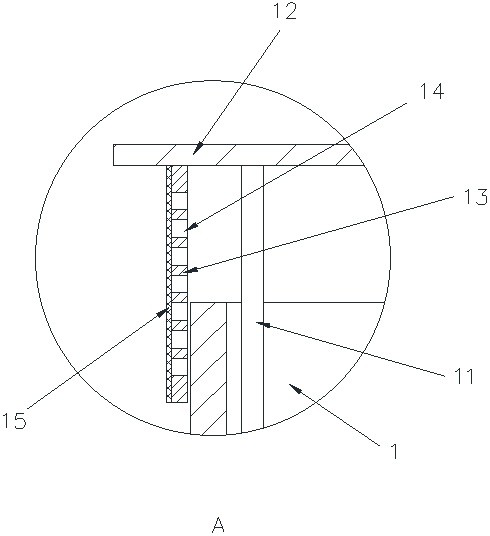

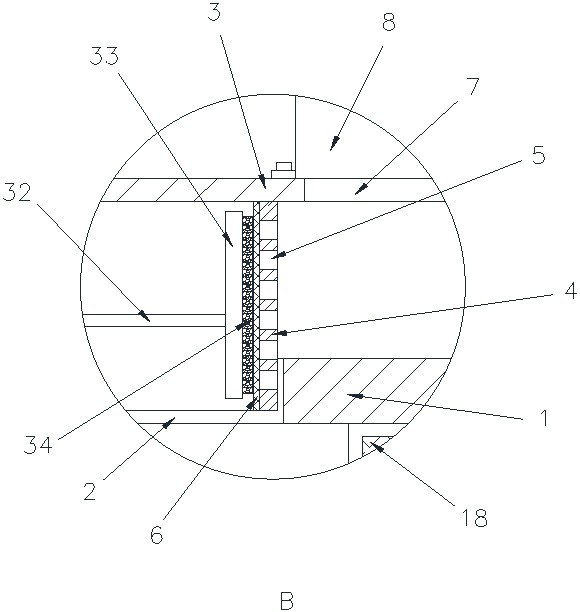

[0036] refer to figure 1 , figure 2 and image 3 In this embodiment, a power monitoring and communication management machine includes: a cylindrical casing 1, a main board 27 installed in the casing 1, and an interface (not shown in the figure) provided on the casing 1. The casing 1 The top of the casing 1 is open, the bottom of the casing 1 is fixed with supporting feet 18, the bottom surface of the casing 1 is provided with a through groove 2, and the bottom of the casing 1 is provided with a supporting plate 3, and the bottom surface of the supporting plate 3 is fixed with a first An annular cover 4, the first annular cover 4 extends downward into the through groove 2, and the first annular cover 4 is coaxial with the through groove 2, and the outer wall of the first annular cover 4 is close to the side wall of the through groove 2. An annular cover 4 is provided with a plurality of air inlet holes 5 .

[0037]A motor 16 is arranged below the support plate 3. The motor ...

Embodiment 2

[0057] refer to Figure 7 and Figure 8 , this embodiment adds a deflector 35 on the basis of the first embodiment. The deflector 35 is arranged just above the fan 8 , and the middle of the deflector 35 is rotatably connected to the casing 1 through the rotating shaft 37 , and a contact block 38 is fixed on the side of the deflector 35 close to the outside of the casing 1 . A support block 39 for supporting the contact block 38 is arranged below the contact block 38 , a first magnet 40 is fixed on the side of the deflector 35 near the middle of the casing 1 , and a blade 41 of the fan 8 is fixed with a first magnet 40 . The second magnet 42 , the first magnet 40 and the second magnet 42 attract each other, and the weight of the contact block 38 is greater than the weight of the first magnet 40 . When the second magnet 42 is close to the first magnet 40, it will attract the first magnet 40 downward, so that the right side of the deflector 35 sinks and the left side of the def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com