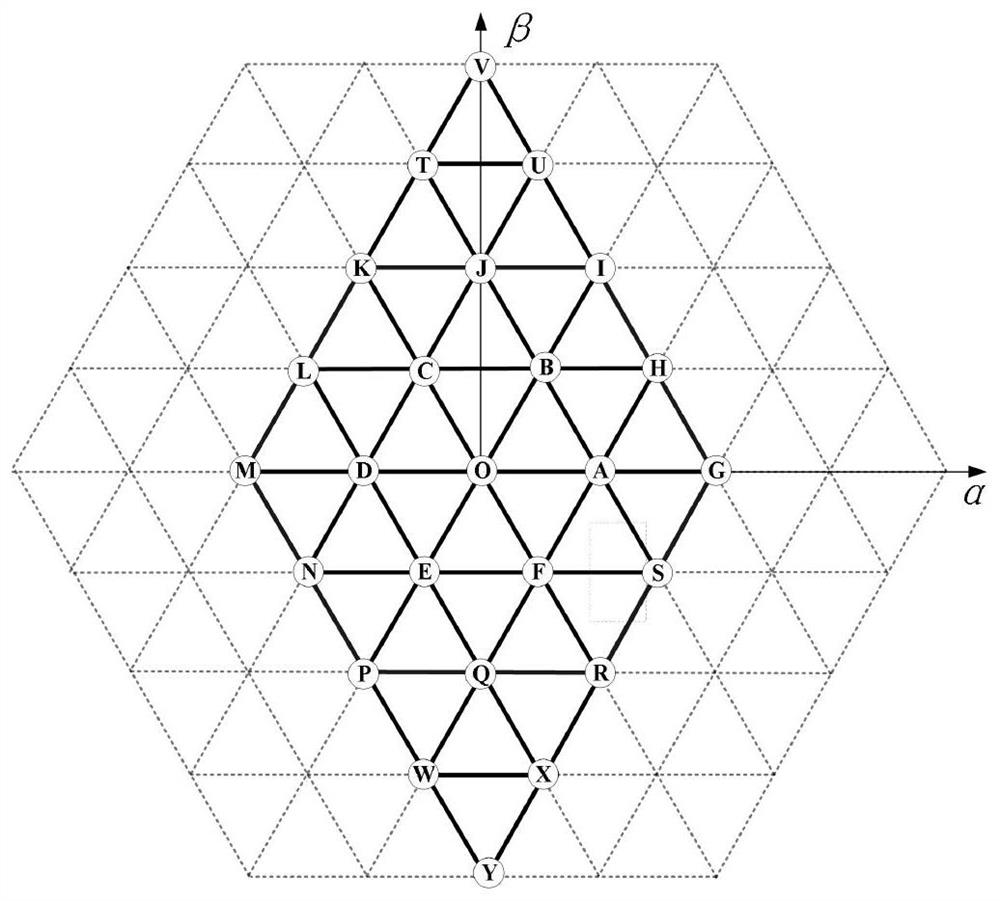

Fault-tolerant control method of dual three-level inverter topology based on vector clamping modulation strategy

A three-level inverter, fault-tolerant control technology, applied in vector control systems, motor generator control, AC motor control, etc. , can not be practically applied and other problems, to achieve the effect of reducing system switching loss, achieving mid-point potential balance, and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing:

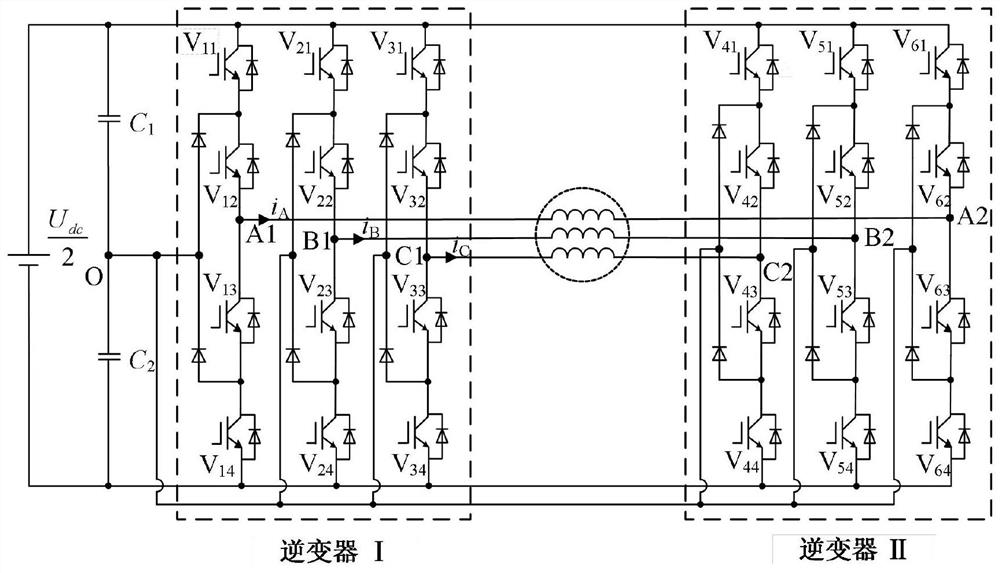

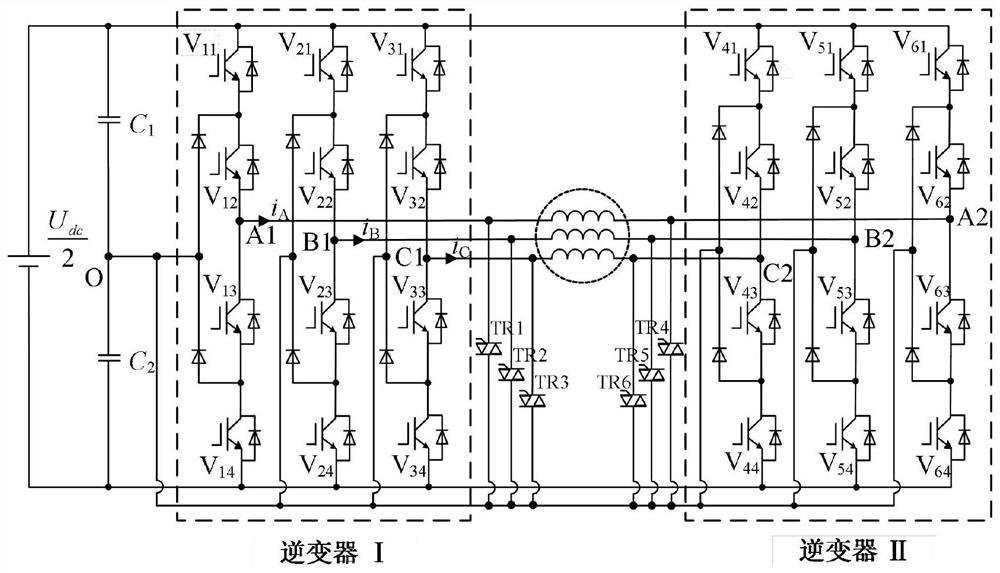

[0057] The dual three-level inverter topology fault-tolerant control method based on the vector clamp modulation strategy of the present invention involves a dual three-level inverter system including inverter I and inverter II, wherein inverter I includes Bridge arm A1, bridge arm B1 and bridge arm C1; inverter II includes bridge arm A2, bridge arm B2 and bridge arm C2, bridge arm A1 is connected to the midpoint of the system through bidirectional thyristor TR1, and bridge arm B1 is connected to the middle point of the system through bidirectional thyristor TR2 The midpoint of the system is connected, the bridge arm C1 is connected to the midpoint of the system through the triac TR3, the bridge arm A2 is connected to the midpoint of the system through the triac TR4, the bridge arm B2 is connected to the midpoint of the system through the triac TR5, and the bridge arm C2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com