Rubber ring blind plugging device

A rubber ring, rubber ring technology, applied in heat exchanger sealing devices, lighting and heating equipment, pipes/pipe joints/pipe fittings, etc. The effect of heat tracing and thermal insulation protection, prolonging the service life and eliminating tedious steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

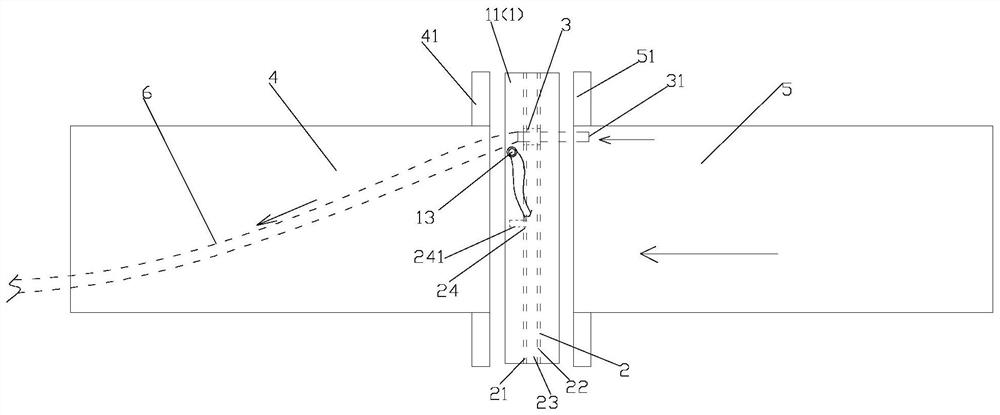

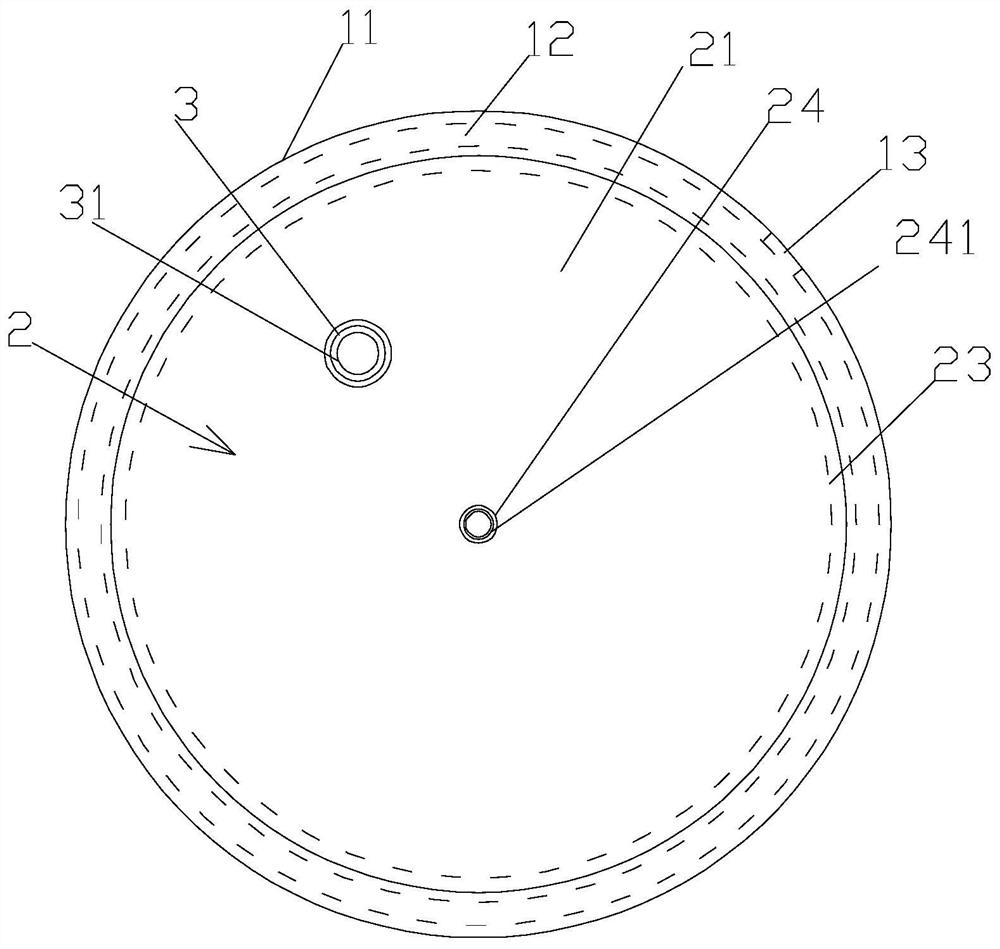

[0024] see Figure 1-2 The rubber ring blind plugging device shown includes a rubber ring 1, a film 2 and a ventilation hole 3. The rubber ring 1 is in the shape of a ring, and the middle part of the rubber ring 1 matches and fixes the film 2. The film 2 is circular. Ventilation holes 3 are provided, and the ventilation holes 3 pass through the film 2 .

[0025] The rubber ring 1 includes an outer ring 11, an inflation cavity 12 and an inflation hole 13. The outer ring 11 is made of an elastic rubber material, the outer ring 11 is provided with an inflation cavity 12, and the side wall of the outer ring 11 is provided with an inflation hole 13, and the inflation hole 13 is connected with the inflation hole. Cavities 12 communicate with each other. Rubber ring 1 selects the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com