Electrolytic degreasing synergist

An electrolytic degreasing and synergistic technology, applied in the field of cleaning agents, can solve the problems of increased corrosion of metal workpiece substrates, decreased water washing performance, and reduced active components, so as to reduce the total amount of pollutants, reduce treatment costs, and reduce replacement. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-4

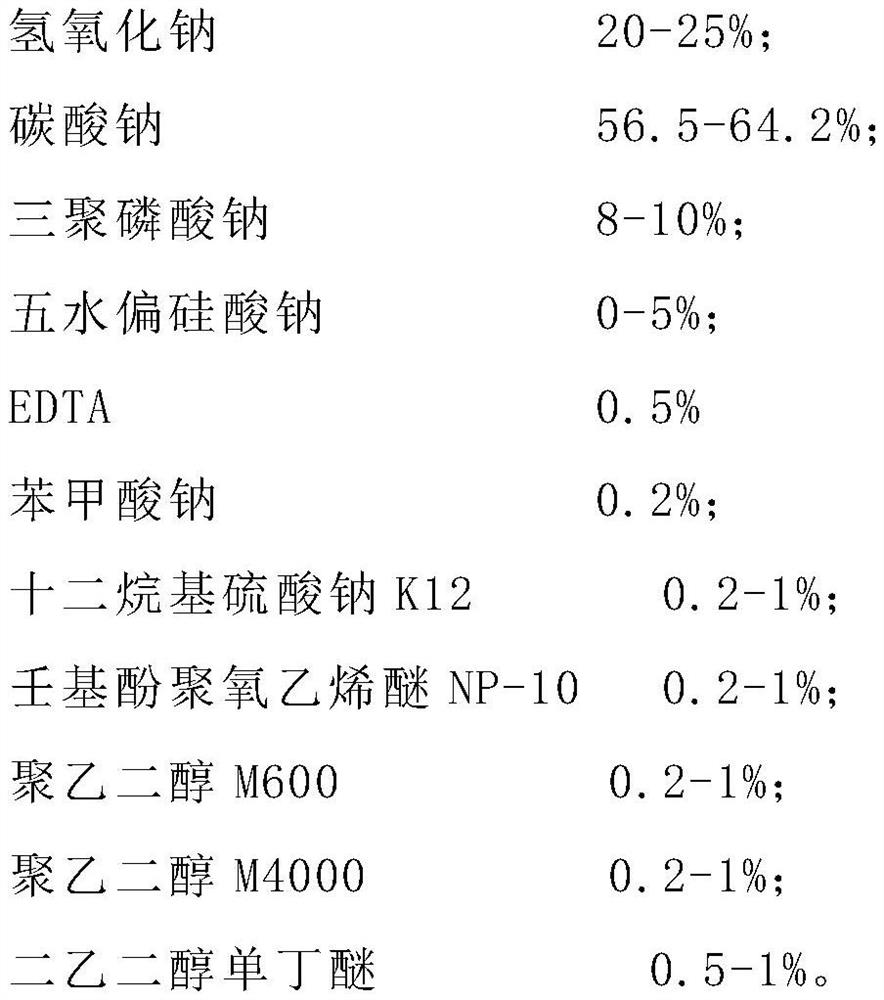

[0053] Prepare raw materials according to the formula table shown in table 1, then prepare electrolytic degreasing synergist according to the following steps:

[0054] 1) Add sodium carbonate, sodium tripolyphosphate, sodium metasilicate pentahydrate, EDTA and sodium benzoate into the powder mixing tank in proportion;

[0055] 2) Then add sodium lauryl sulfate, nonylphenol polyoxyethylene ether, low-molecular-weight polyethylene glycol, high-molecular-weight polyethylene glycol and diethylene glycol monobutyl ether in proportion, and add it to the stirring tank under stirring conditions, well mixed;

[0056] 3) Add sodium hydroxide, continue to stir and mix evenly, and sample inspection;

[0057] 4) Pack and ship after passing the inspection.

[0058] Table 1 Electrolytic degreasing synergist formula table (unit: parts by weight)

[0059]

[0060] The performance evaluation verification method of the electrolytic synergist of embodiment and comparative example:

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com